Automatic manufacturing method of steel grid plate

A manufacturing method and steel grating technology, applied in the field of steel grating manufacturing, can solve problems such as poor quality of welding points, low production efficiency, virtual welding, etc., achieve consistent size and shape, improve labor efficiency, and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

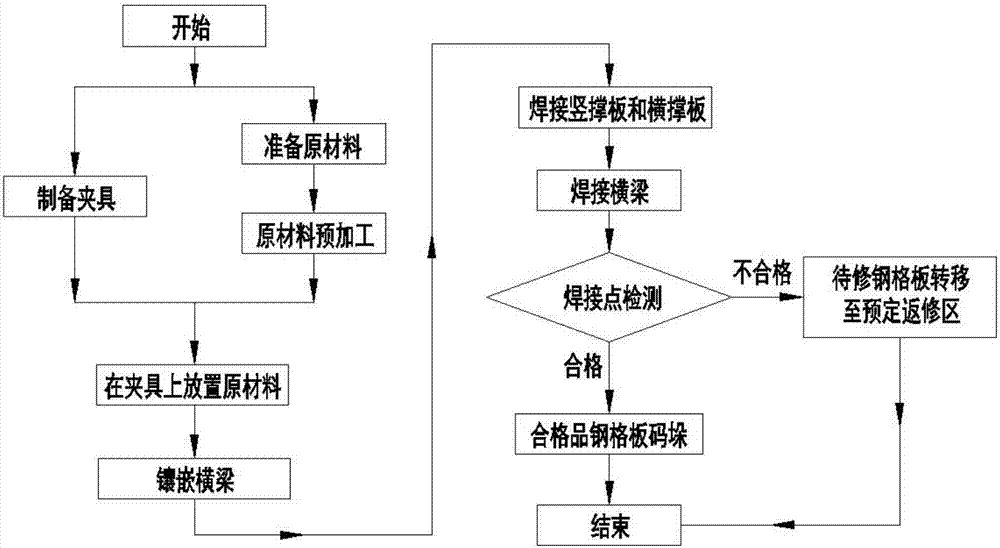

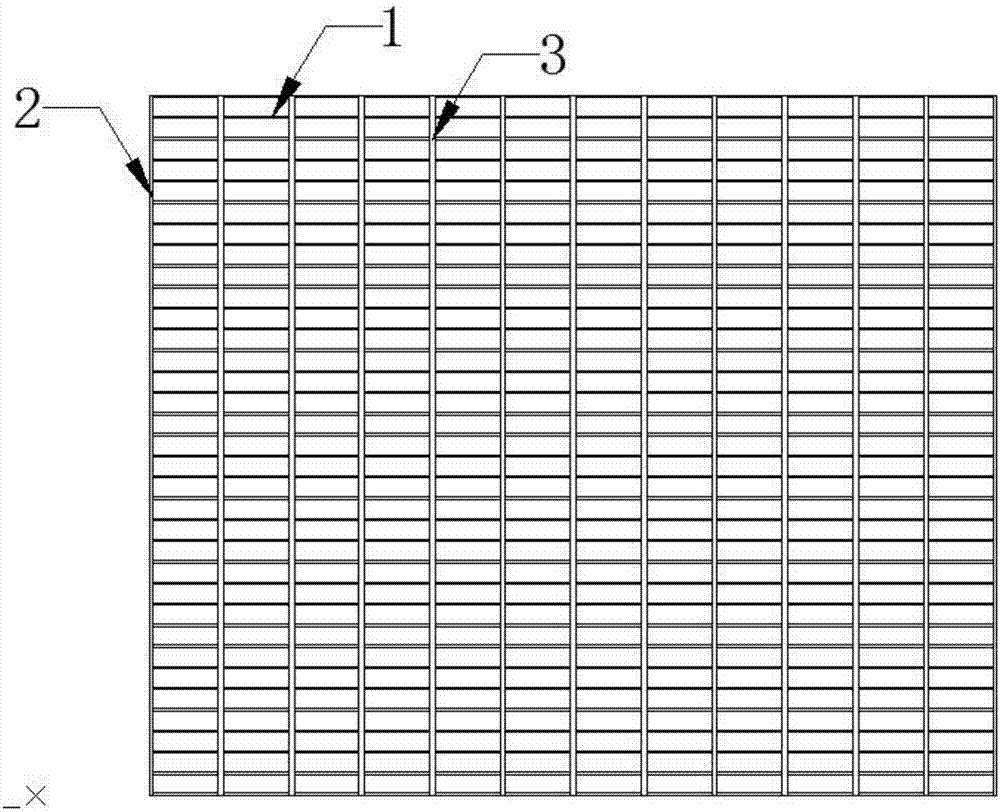

[0035] The invention provides an automatic manufacturing method for a steel grating, such as Figure 1 to Figure 6 shown, including the following steps:

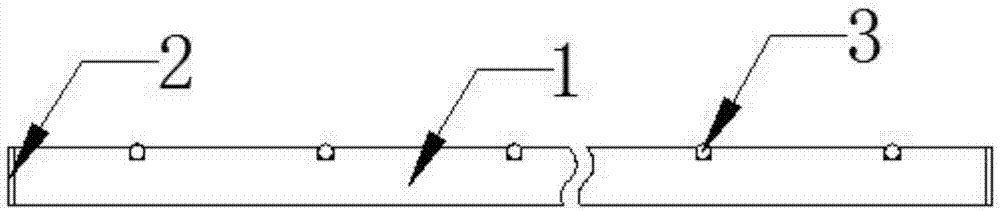

[0036] Step 1: Prepare raw materials: Prepare several vertical braces 1 of equal length, at least two horizontal braces 2 of equal length, and several beams 3 of equal length; further, the horizontal braces 2 and vertical braces 1 in Step 1 All flat steel. The crossbeam 3 in step 1 is rebar or twisted square steel. Further, the total number of cross braces 2 and vertical braces 1 is 34, of which there are two cross braces 2 and eleven cross beams 3 . Other specifications are the same.

[0037] Step 2: raw material pre-processing: using a punching machine to process several supporting grooves 4 with the same position, shape and size on one side edge of each vertical support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com