A kind of ultra-high basicity vanadium-titanium sinter and production method thereof

A technology for vanadium-titanium sintered ore and production method, which is applied in the field of iron and steel smelting to achieve the effects of suitable mechanical strength and reducibility, reducing sintering speed and increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

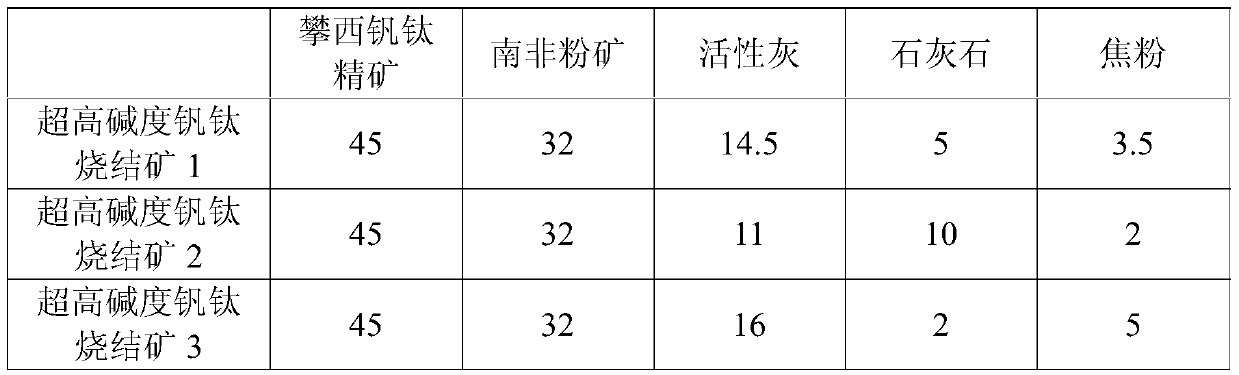

Examples

Embodiment

[0031] Use ultra-high alkalinity vanadium-titanium sinter 1 for batching, according to the control parameters of process 4 in Table 4, other parameters remain unchanged, after mixing, the particle size of the mixture is 75.31% above +3mm.

[0032] The results of the benchmark example are as follows: the obtained R is 3.3, the TFe content of the sintered ore is 48.08%, the FeO content is 7.04%, and the TiO 2 The ultra-high alkalinity sinter with a content of 5.12% and a drum index of 73.23% has a sintering time of 34 minutes and a utilization factor of 1.213t / m for the sintering machine 2 .h, the sintering yield is 82.62%.

Embodiment 1

[0035] The results of Example 1 are as follows: the obtained R is 3.3, the sinter TFe content is 48.11%, the FeO content is 7.64%, and the TiO 2 The ultra-high alkalinity sinter with a content of 5.35% and a drum index of 73.41% has a sintering time of 47 minutes and a utilization factor of 0.943t / m for the sintering machine 2 .h, the sintering yield is 78.25%.

Embodiment 2

[0038] The results of Example 2 are as follows: the obtained R is 3.3, the sinter TFe content is 48.17%, the FeO content is 10.64%, and the TiO 2 The ultra-high alkalinity sinter with a content of 5.15% and a drum index of 74.71% has a sintering time of 26 minutes and a sintering machine utilization factor of 1.121t / m 2 .h, the sintering yield is 75.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com