Preparation method and application of foamed surimi slurry

A technology for foaming fish and surimi products, which is applied in the field of preparation of foamed surimi slurry, can solve problems such as activity instability, product batch differences, and foaming degree differences, and achieve stable foaming state and high quality. Fluffy and juicy texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

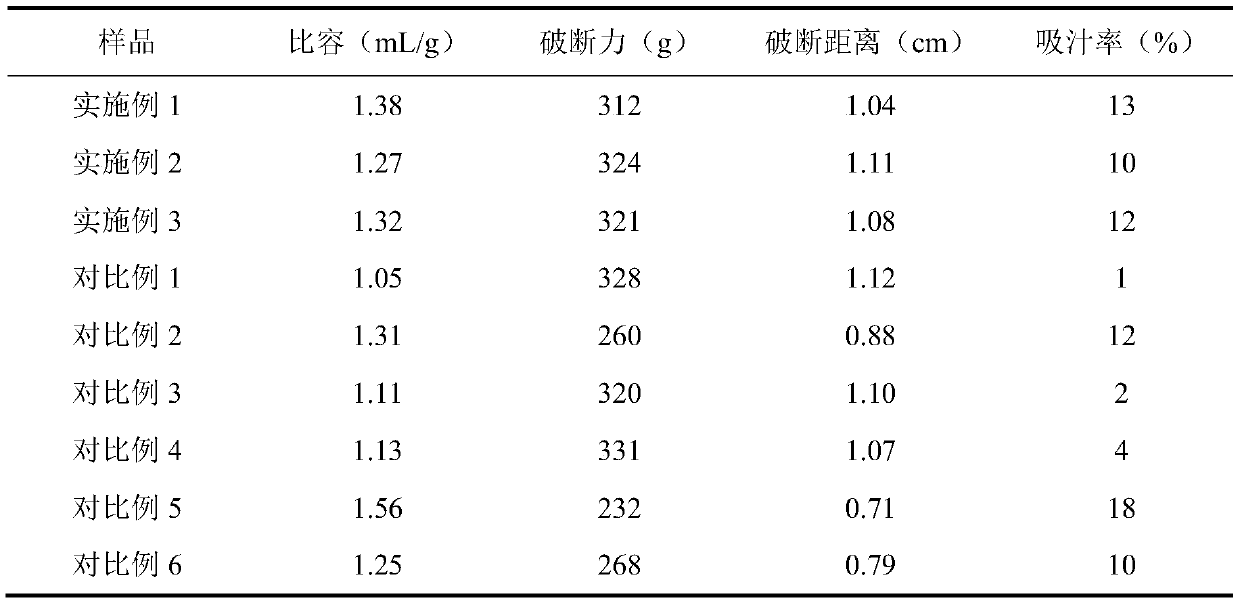

Examples

Embodiment 1

[0030] A processing method of foamed surimi, the method comprising the following steps:

[0031] (1) Preparation of basic surimi slurry: take 60 parts of semi-thawed frozen surimi flakes according to the number of parts by weight, and chop them in the air at low speed in a chopper until there are no hard particles; add 2.0 parts by weight of edible salt and chop at high speed. Until the slurry is fine, viscous and glossy; then add 10 parts by weight of starch, 6 parts by weight of minced fat, 20 parts by weight of ice water, 2 parts by weight of seasonings, and mix at high speed until the slurry is uniform and fine. When the material discharge temperature does not exceed 6°C, the basic surimi slurry is obtained.

[0032] (2) Preparation of foamed surimi slurry: Take 100 parts by weight of basic surimi slurry and put it into the whisk, add 0.05 parts by weight of sodium polyacrylate and 3 parts by weight of pre-gelatinized tapioca starch, turn on the whisk for stirring and aeration ...

Embodiment 2

[0035] With reference to the method of Example 1, the weight ratio of basic surimi slurry: foamed surimi slurry was adjusted to 55:45.

Embodiment 3

[0037] With reference to the method of Example 1, the time spent was adjusted to 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com