Stainless steel water tank

A stainless steel and water tank technology, applied in the field of stainless steel products, can solve problems such as easy breeding of bacteria and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

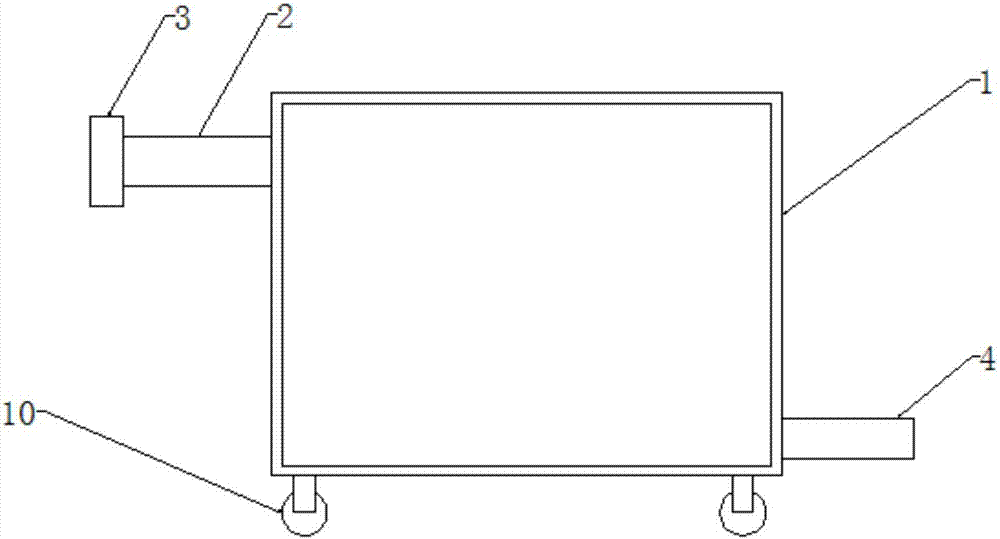

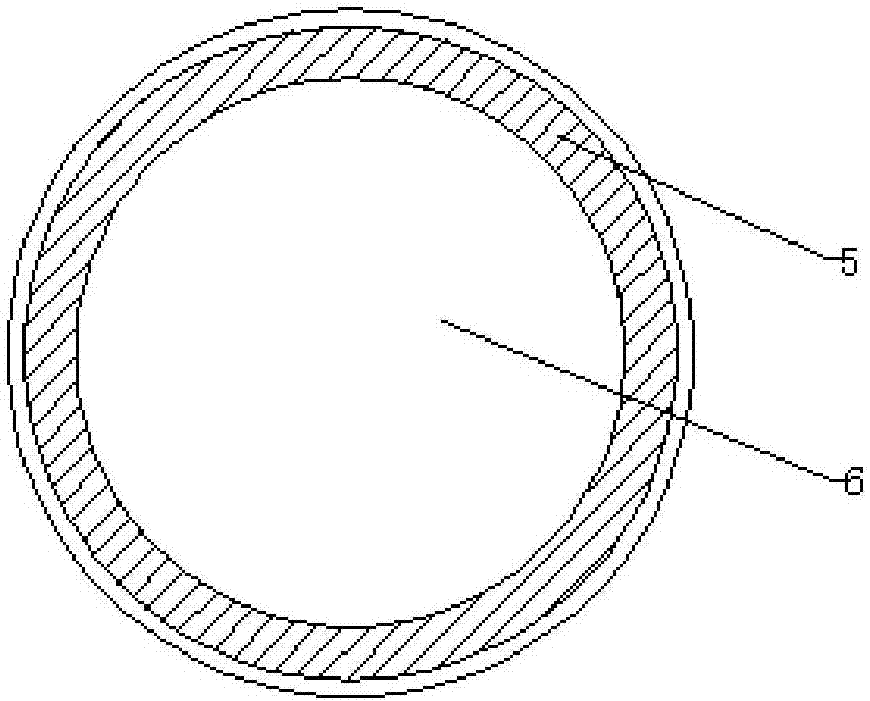

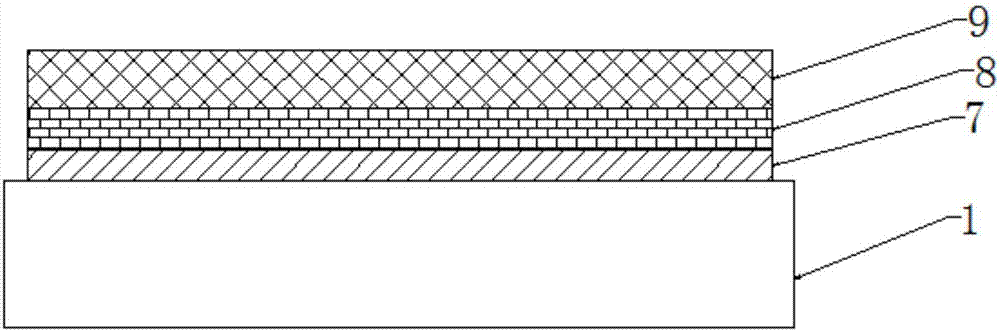

[0018] The reference signs in the drawings of the specification include: box body 1, water inlet 2, cover 3, water outlet 4, sealing layer 5, antibacterial film 6, zinc layer 7, copper layer 8, composite layer 9, universal wheel 10 .

[0019] Such as figure 1 , figure 2 and image 3 As shown, the application provides a stainless steel water tank, comprising a tank 1, the tank 1 is provided with a water inlet 2 and a water outlet 4, the water inlet 2 is connected with a cover 3, the cover 3 and the water inlet 2 are connected by threads, The lid 3 is connected with an annular sealing layer 5, the sealing layer 5 is made of rubber, and the lid 3 is also coated with an antibacterial film 6. The inner surface of the box body 1 is also coated with an antibacterial coating, the zinc layer 7, the copper layer 8 and the composite layer 9 successively connected by the antibacterial coating, the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com