A led light structure

A technology of LED lamp structure and LED lamp beads, which is applied in lighting and heating equipment, light sources, components of lighting devices, etc. problems, to achieve the effect of improving the cooling effect, ensuring the use effect and service life, and improving the speed of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

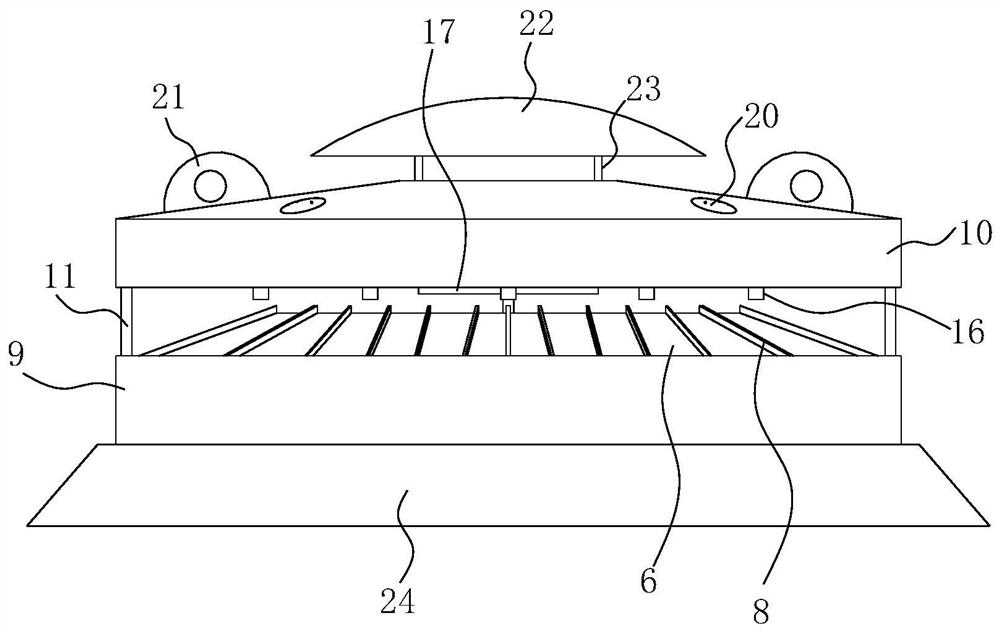

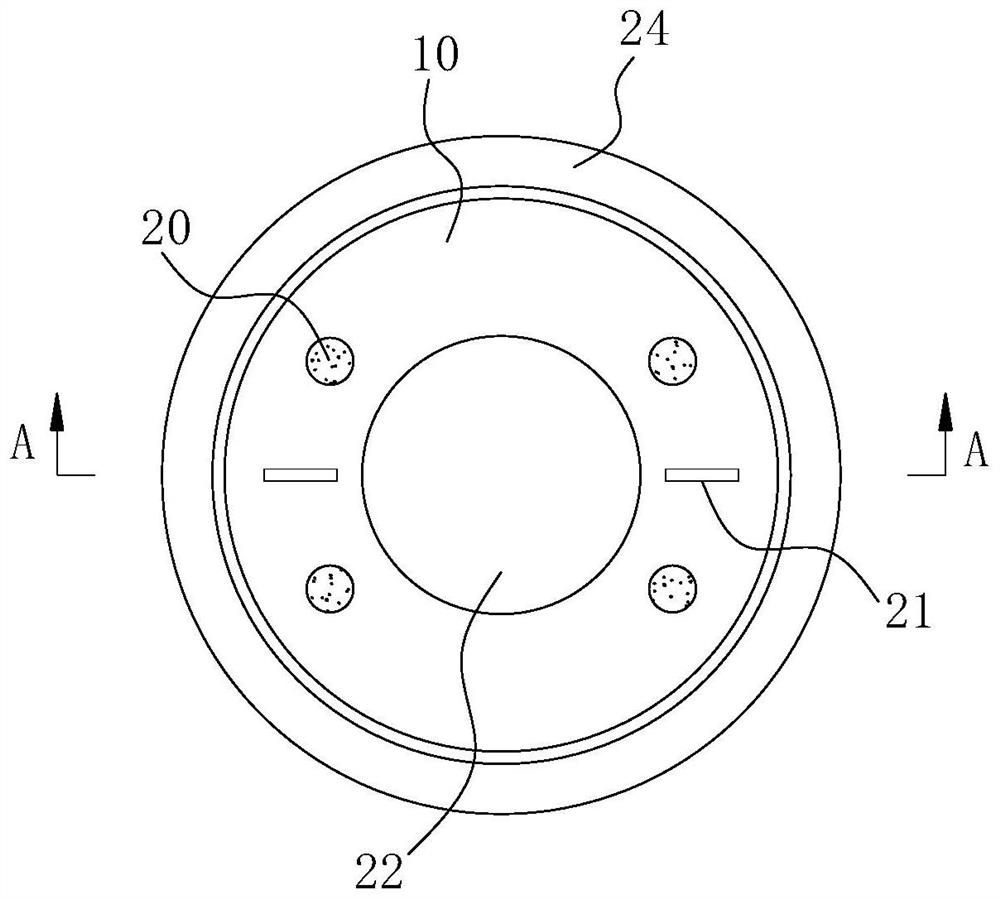

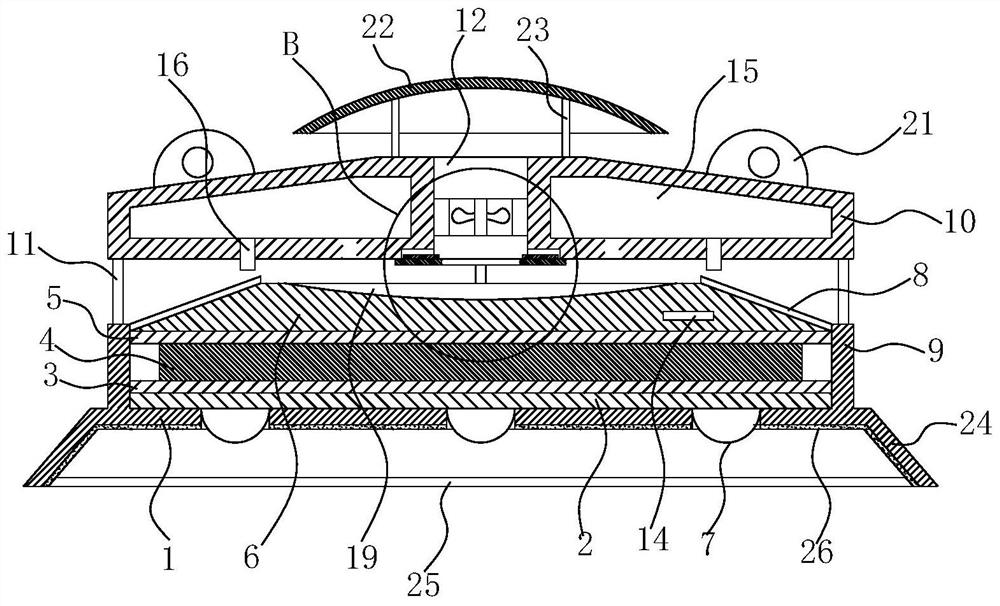

[0028] combine Figure 1-5 The LED lamp structure shown includes a board body 1. The shape of the board body 1 can be set according to the actual needs of the LED lamp. For example, when the LED lamp is generally rectangular, the board body 1 can be rectangular. When the LED lamp When the overall shape is circular, the plate body 1 can be rotated circularly. For the convenience of description, a circular shape is taken as an example in the figure. Such as image 3 As shown, the upper surface of the board body 1 is provided with a mounting substrate 2 , a first semiconductor cooling fin 3 , a heat conduction plate 4 , a second semiconductor cooling fin 5 and a heat dissipation block 6 in sequence along a direction away from the board body 1 . That is to say, the installation substrate 2, the first semiconductor cooling chip 3, the heat conduction plate 4, the second semiconductor cooling chip 5 and the heat dissipation block 6 are arranged sequentially from bottom to top, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com