Method for determining caprylin and caprin in cigarette blasting bead

A technology of glyceryl caprate and glyceryl tricaprylate, which is applied in the field of chemical analysis and testing, can solve the problems of difficulty in obtaining and restricting the calibration of classical chromatographic analysis methods, and achieve simplification of calculation difficulty, easy operation of pretreatment methods, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

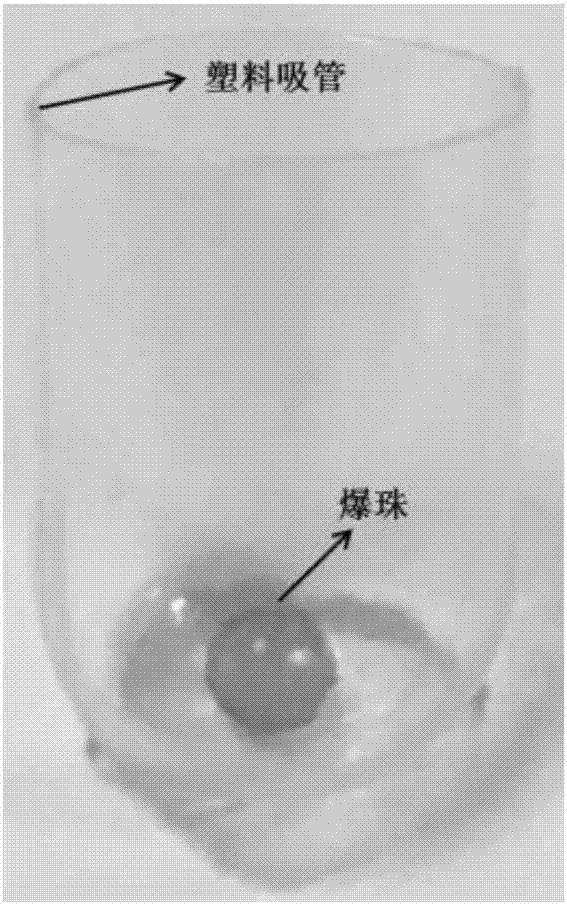

[0058] The assay method of capric acid glyceride in the cigarette quick-fried pearl of the present embodiment, such as figure 1 shown, including the following steps:

[0059] 1. Preparation of test solution

[0060] Take a cigarette popping bead and weigh its mass (accurate to 0.1mg), put the popping bead on the bottom of the cut plastic straw such as figure 2 As shown, after crushing the pop-up beads, put them together with the straw into a 50mL stoppered centrifuge tube, add 10mL n-hexane and 100μL internal standard solution, vortex for 5min, and take the supernatant to obtain the test solution; the internal standard solution is 25mg / mL n-hexane solution of n-hexadecane;

[0061] 2. Preparation of standard working solution

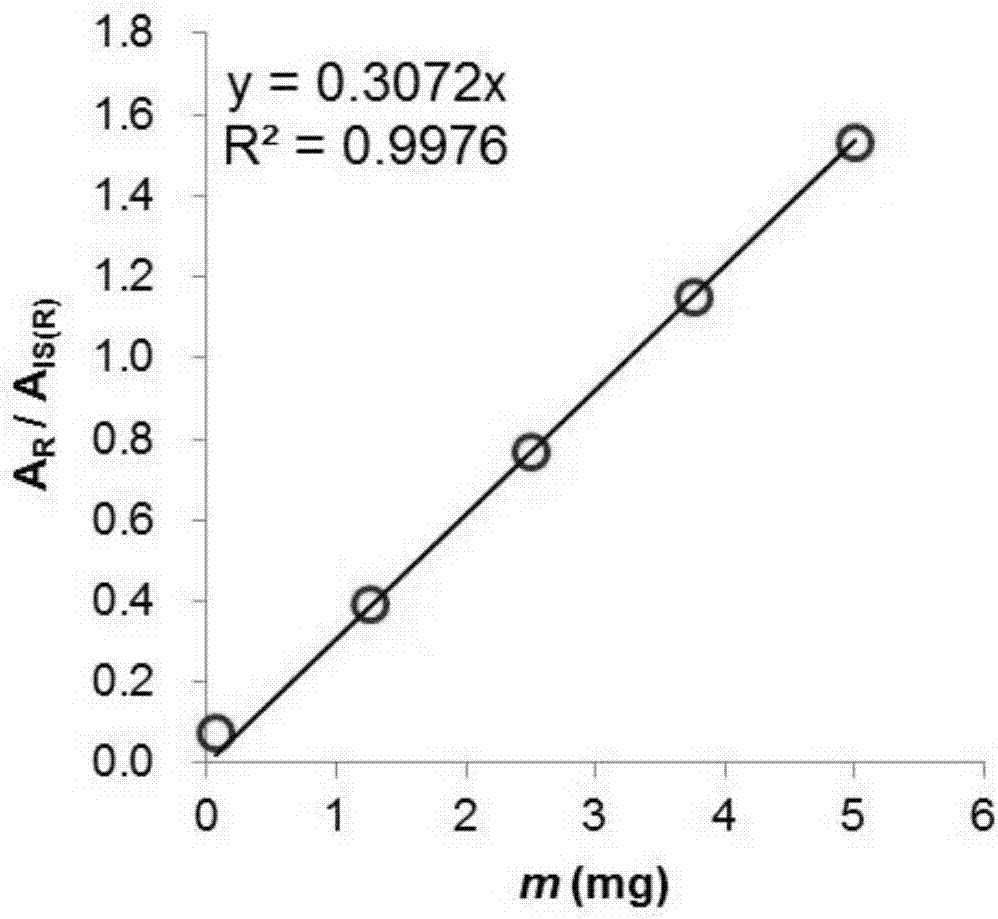

[0062] Weigh 25mg (accurate to 0.1mg) tricaprylic acid glyceride in a 10mL volumetric flask, dissolve it with n-hexane and set the volume to the mark, and prepare a standard stock solution with a concentration of 2.5mg / mL; pipette 0.025mL, 0.5 mL, 1...

Embodiment 2

[0078] Caprylic, capric acid glyceride food additive is measured according to the assay method of embodiment 1, and the gas chromatogram that records is as follows Figure 4 as shown, Figure 4 The middle chromatographic peaks 3-9 are glyceryl dicaprylate, glyceryl monocaprylate, glyceryl dicaprate, glyceryl tricaprylate, glyceryl monocaprylate dicaprylate, glyceryl monocaprylate dicaprate, tricapric acid The chromatographic peak of glyceride, IS is the chromatographic peak of n-hexadecane, and monocaprylic acid glyceride and monocapric glyceride are not detected.

Embodiment 3

[0080] According to the assay method of Example 1, the content of caprylic and capric glycerides in samples 1-1, 1-2, and 1-3 of unknown cigarette quick-fried pearls is shown in Table 4, and the gas chromatogram of the 1-1 sample is shown in Table 4. Figure 5 As shown, wherein the chromatographic peaks 3-9 are successively glyceryl dicaprylate, glyceryl monocaprylate, glyceryl dicaprate, glyceryl tricaprylate, glyceryl monocaprate dicaprylate, glyceryl monocaprylate dicaprate, The chromatographic peak of glyceryl tricaprate, IS is the chromatographic peak of n-hexadecane, glyceryl monocaprylate and glyceryl monocaprate are not detected.

[0081] Table 4 Statistical results of actual samples

[0082]

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com