Graphene-copper composite core light-weight fireproof flexible cable used for data center power supply

A data center and graphene technology, applied in the direction of power cables, insulated cables, bendable cables, etc., can solve problems such as easy to break, difficult to batch, high energy consumption, etc., to achieve improved insulation and increased softness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

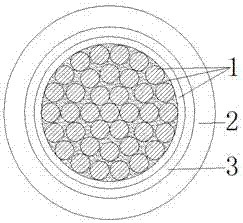

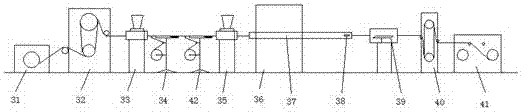

[0031] like figure 1 As shown, it is the graphene-copper composite core light-weight fire-resistant flexible cable for data center power supply of the present invention. Vinyl insulation2.

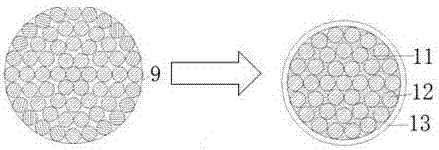

[0032] Graphene-copper composite core 1 of the present invention is made up of soft copper monofilament 12, graphene conductive glue 11 and semi-conductive elastic wrapping tape 13; Described soft copper monofilament 12 is twisted and formed copper wire, and described The graphene conductive glue 11 is filled in the gaps of the copper wires; the semiconductive elastic tape 13 is longitudinally wrapped around the copper wires filled with the graphene conductive glue 11 .

[0033] The flexible copper monofilament 12 of the present invention is an annealed copper wire with a conductor monofilament diameter between 0.10 and 0.20mm, and the elongation rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com