An electric motor for driving an ABB system

A technology of ABS system and electric motor, applied in the direction of electric components, synchronous motor with stationary armature and rotating magnet, manufacturing motor generator, etc., can solve problems such as limitations, achieve manufacturability, high efficiency, reduce Effect of small risk of demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

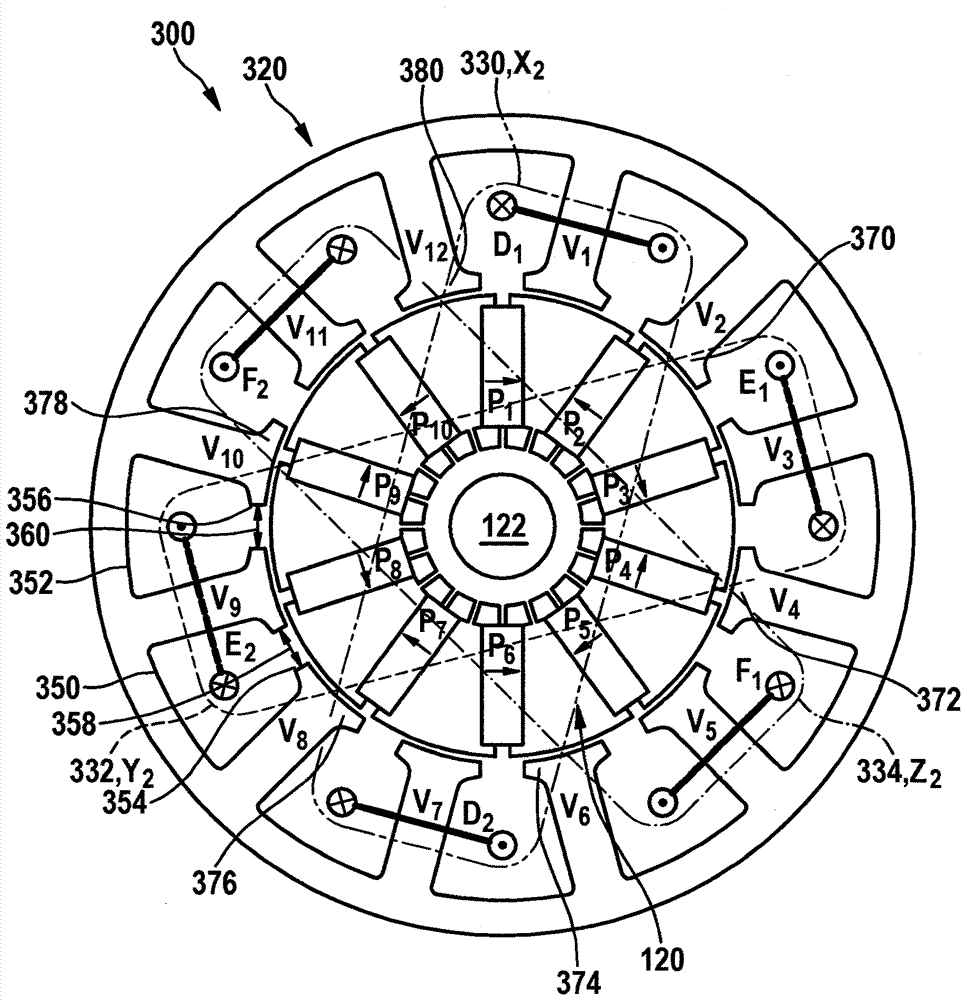

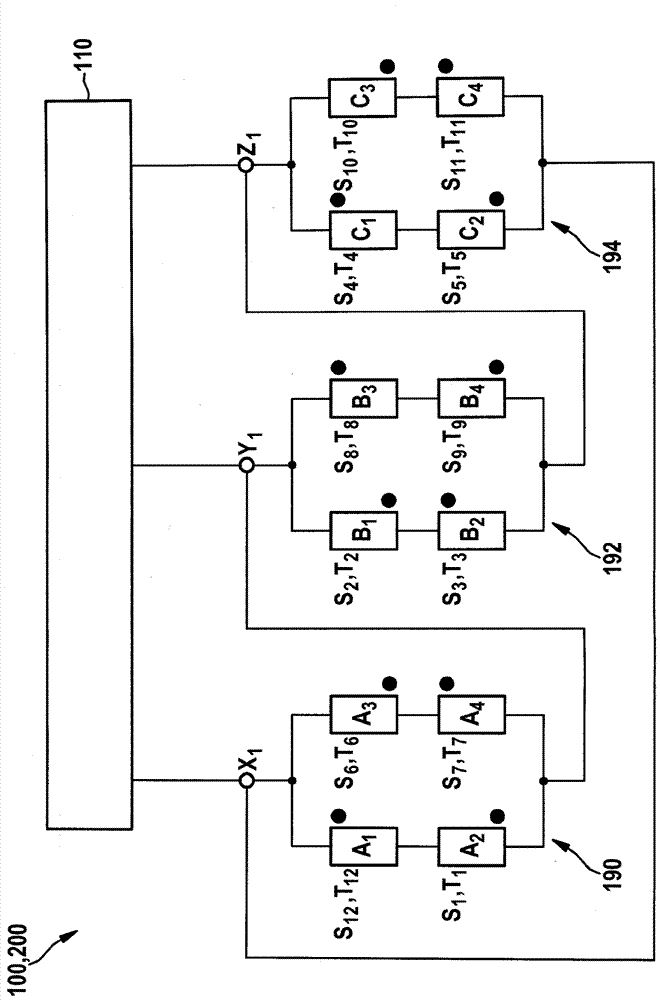

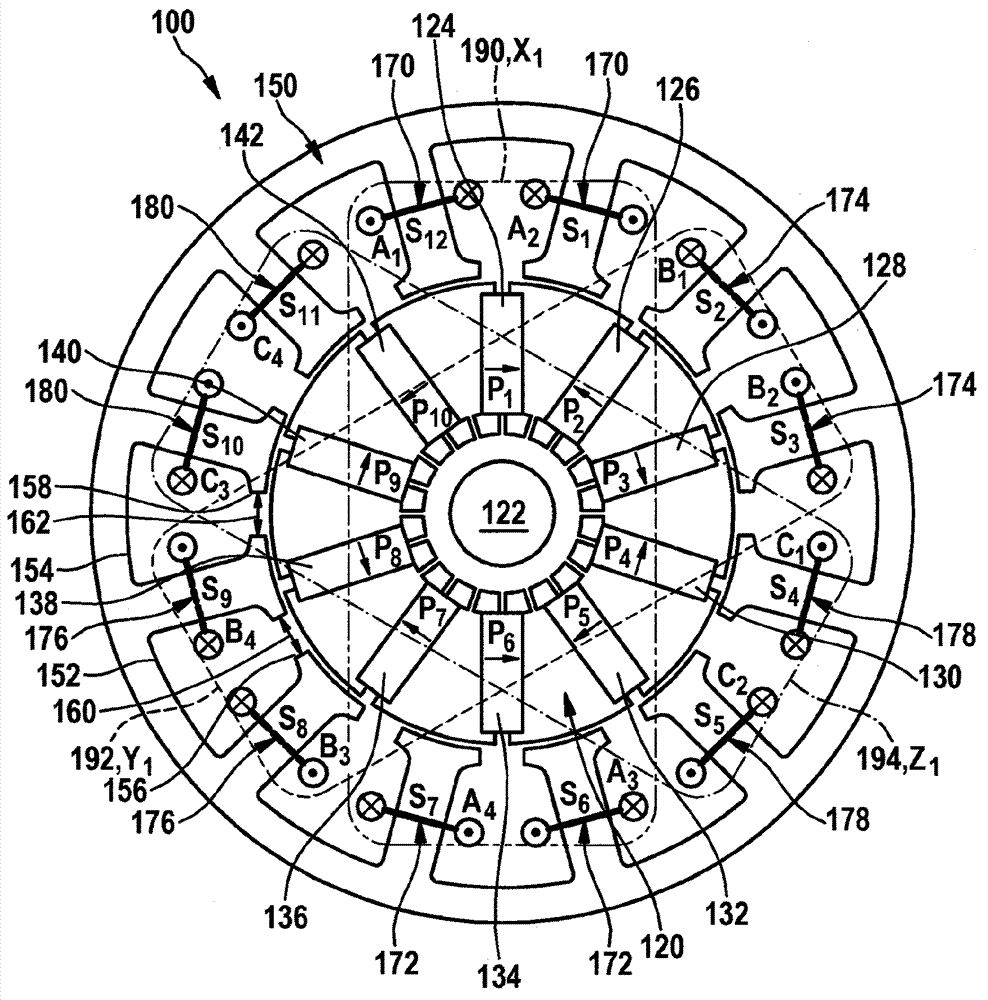

[0034] figure 1 An electric motor 100 , which is embodied as an example of an inner rotor motor with an inner rotor 120 and an outer stator 150 , is shown. The inner rotor 120 is preferably rotatably mounted on a rotor shaft 122 and coaxially surrounded by an outer stator 150 . In the ensuing description, the inner rotor 120 is simply referred to as the concept "rotor", and the outer stator 150 is simply referred to as the term "stator".

[0035] It is pointed out below that, figure 1 The electric motor 100 is shown only in principle, because the basic structure and function of suitable electric motors are well known from the prior art, thus for the sake of brevity and simplicity of the description, a detailed description of the electric motor 100 is omitted here. instruction of. Furthermore, it should be pointed out that the electric motor 100 is only shown as an example and is not intended to limit the invention as an inner rotor motor. It should also be mentioned that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com