All-metal screw pump heavy oil injection and production integrated control device and method

A control device and screw pump technology, which are applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of increasing the operation cost and construction risk, reducing the service life of the screw pump, and lowering the error, etc. The probability of occurrence of safety accidents, the effect of reducing construction costs and operation time, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

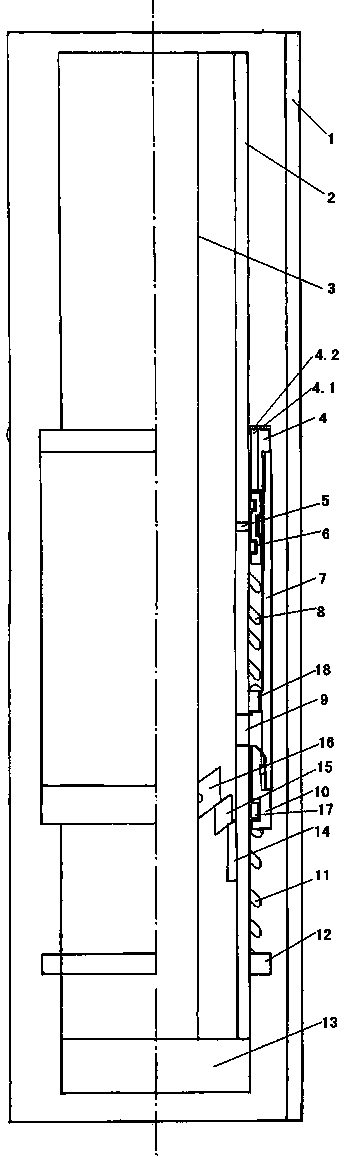

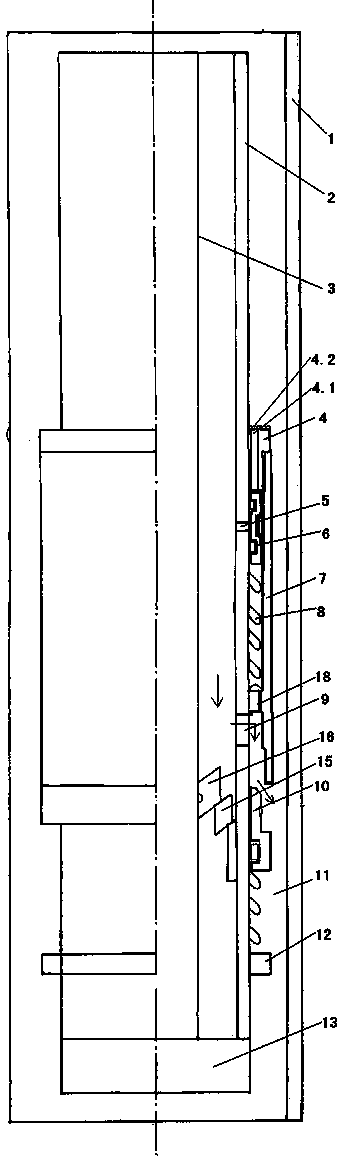

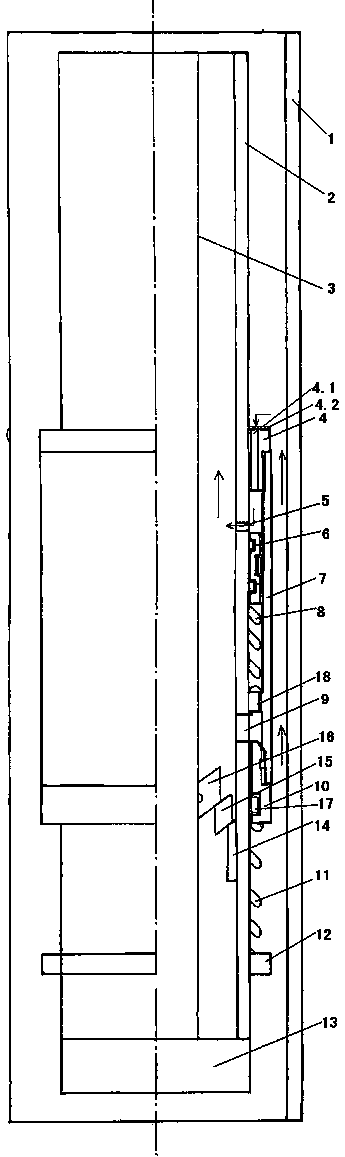

[0028] Embodiment 1, with reference to attached figure 1 , an all-metal screw pump heavy oil injection and production integrated control device mentioned in the present invention, its technical solution is: including a central tube 2, a rotor connecting rod 3, a pressure relief piston 6, a cylinder liner 7, a pressure relief spring 8, an injection Steam piston 10, steam injection spring 11, spring stopper 12, screw pump joint 13, fixed ring 14, movable ring 15, sliding ring 16, connecting protrusion 18, the central tube 2 is installed in the inner cavity of the casing 1, The rotor connecting rod 3 is installed in the inner cavity of the central tube 2, and the rotor connecting rod 3 is connected to the rotor of the all-metal screw pump through the screw pump joint 13. A sliding ring 16 is installed, and a movable ring 15 is installed between the fixed ring 14 and the sliding ring 16; the outside of the middle part of the center pipe 2 is fixed to the cylinder liner 7 by connec...

Embodiment 2

[0041] Embodiment 2, the difference between the present invention and Embodiment 1 is: the pressure relief piston 6 mentioned in the present invention is an arcuate structure, the center position of the pressure relief piston 6 is facing the pressure relief hole 5, and the lengths of both sides are equal, so It is more conducive to steam injection, and the pressure relief hole remains closed.

Embodiment 3

[0042] Embodiment 3, the difference between the present invention and Embodiment 1 is that a steam injection buffer chamber is formed between the outside of the steam injection hole 9 and the cylinder liner 7 of the present invention, and a steam injection piston 10 is located below the steam injection buffer chamber, so The steam injection piston 10 has a narrow top and a thick bottom, and the upper outer wall is in contact with the cylinder liner 7 through a metal seal, and the lower inner wall of the steam injection piston 10 is in contact with the central tube 2 through a metal seal. In addition, the top of the steam injection piston 10 has a right-angled trapezoidal cross-section, and the shapes of the steam injection buffer chamber and the steam injection piston 10 are conducive to the smooth movement of the high-temperature and high-pressure steam to push the steam injection piston 10 downward, avoiding the occurrence of the steam injection piston 10. Locked fault.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com