Method for testing producing profiles of horizontal well through coiled tubing optical fiber technology

A production profile and horizontal well technology, which is used in surveying, earthwork drilling, wellbore/well components, etc., can solve the problem of difficult to accurately monitor the whole wellbore profile, and difficult to implement the production profile test of highly deviated horizontal wells, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

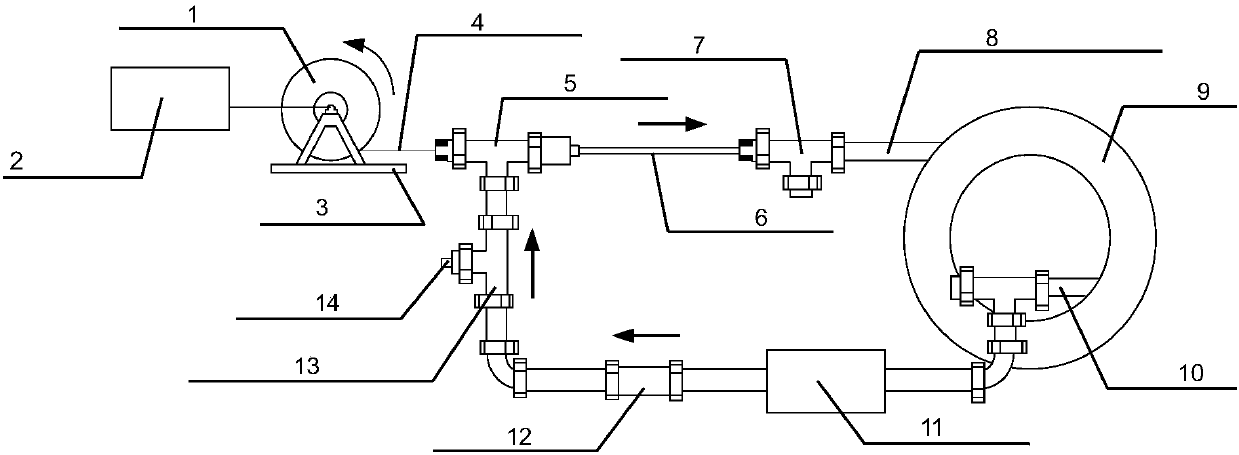

Method used

Image

Examples

Embodiment 1

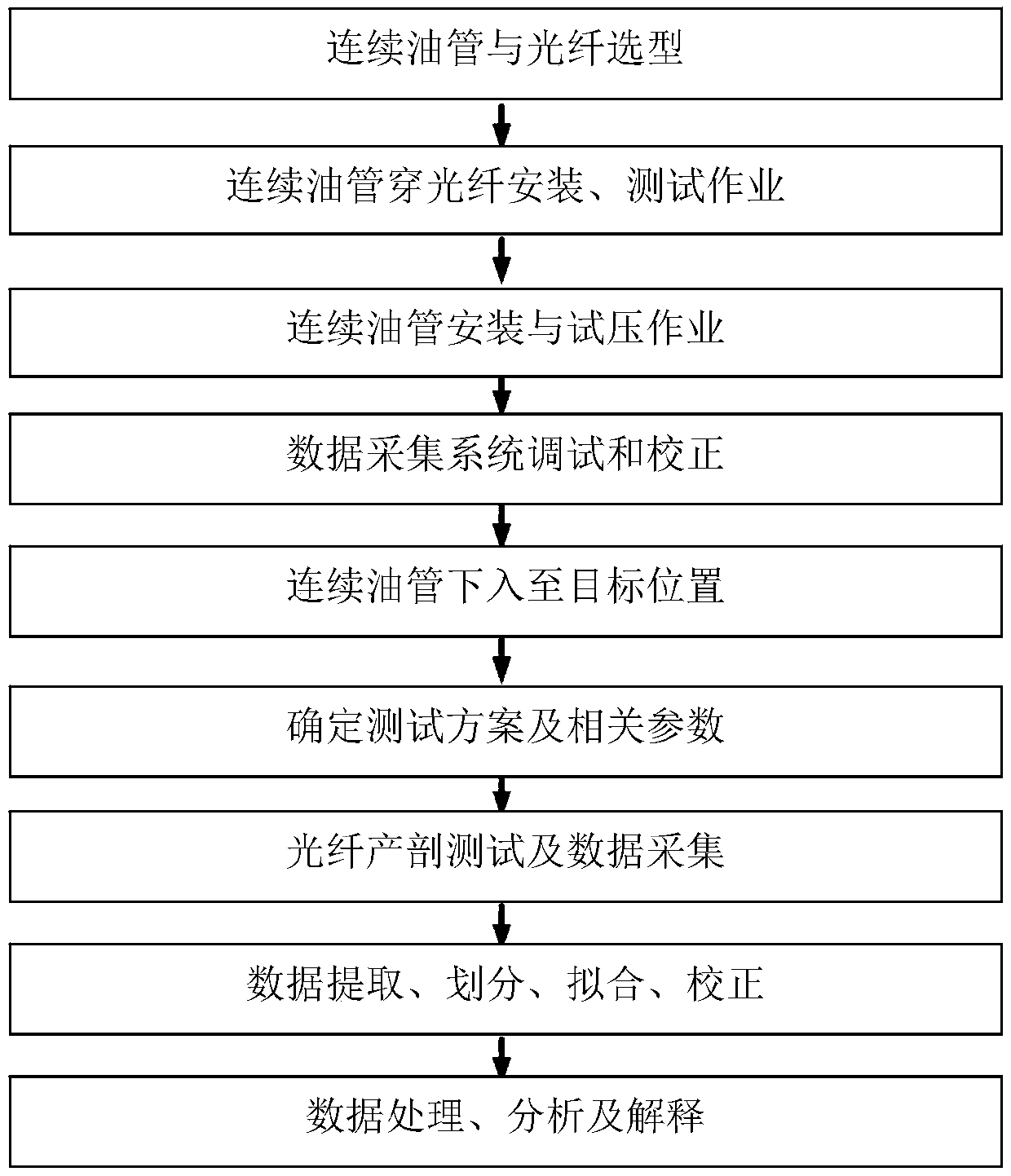

[0096] This embodiment provides a method for testing the production profile of a horizontal well using coiled tubing optical fiber technology, and its specific process flow chart is as follows figure 2 shown, from figure 2 It can be seen that the method includes the following steps:

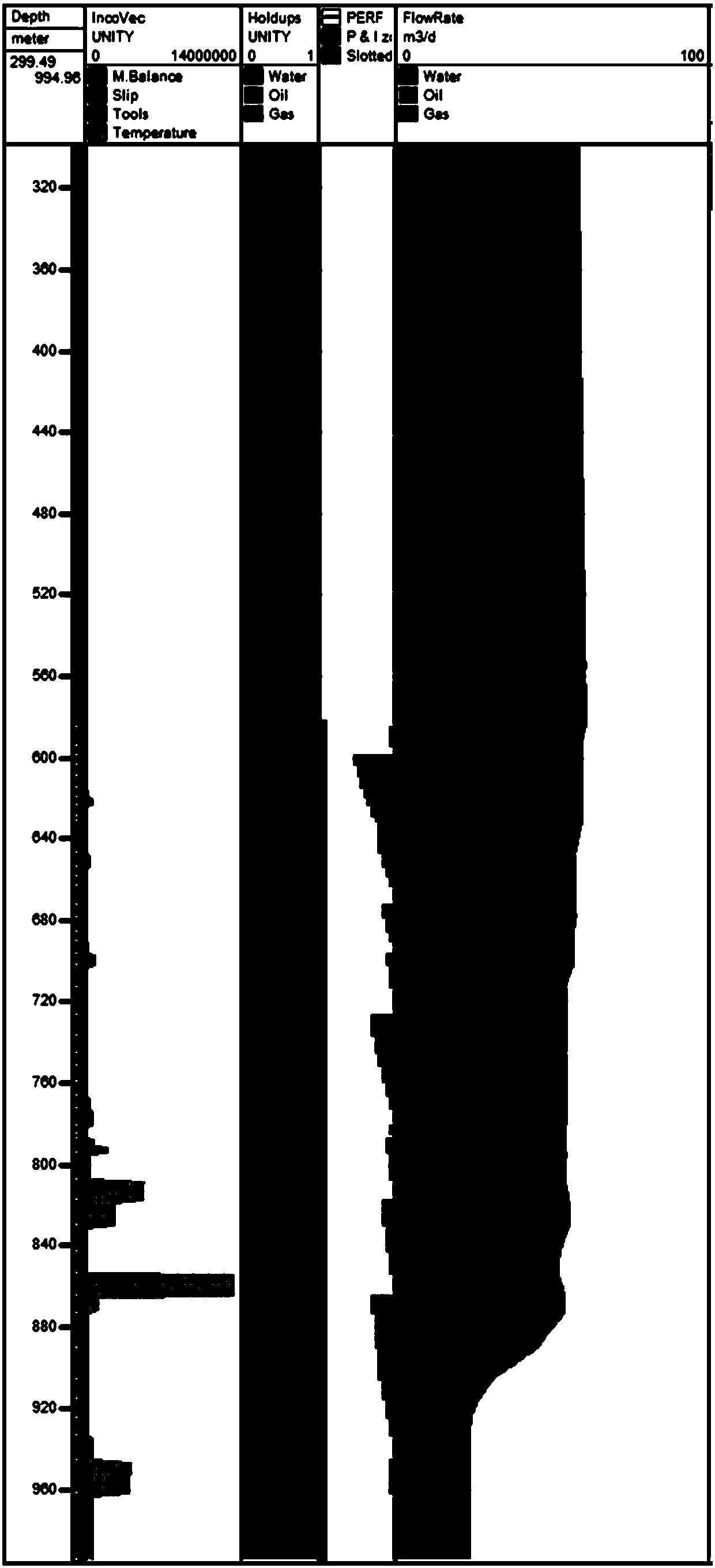

[0097] Take the test production profile of a horizontal well XX-1 as an example.

[0098] (1), coiled tubing and optical fiber selection:

[0099] The outer diameter of the casing used in this horizontal well is 139.7mm, the inner diameter is 115.02mm, the completed drilling depth is 4498.0m, the actual exploration artificial well bottom is 4465.0m, the horizontal well section length is 1645.0m, and the reservoir temperature is 160°C. Analyze data such as the trajectory of the horizontal well itself and the integrity of the wellbore, and at the same time use the coiled tubing mechanical simulation analysis software to perform mechanical simulation, limit simulation, and coiled tubing producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com