A Method of Improving the Performance of Metal Capacitor TDDB

A technology of metal capacitance and performance, applied in the direction of capacitors, circuits, electrical components, etc., can solve problems such as chip failure and easy breakdown of capacitors, and achieve the effects of increasing service life, improving breakdown resistance, and repairing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

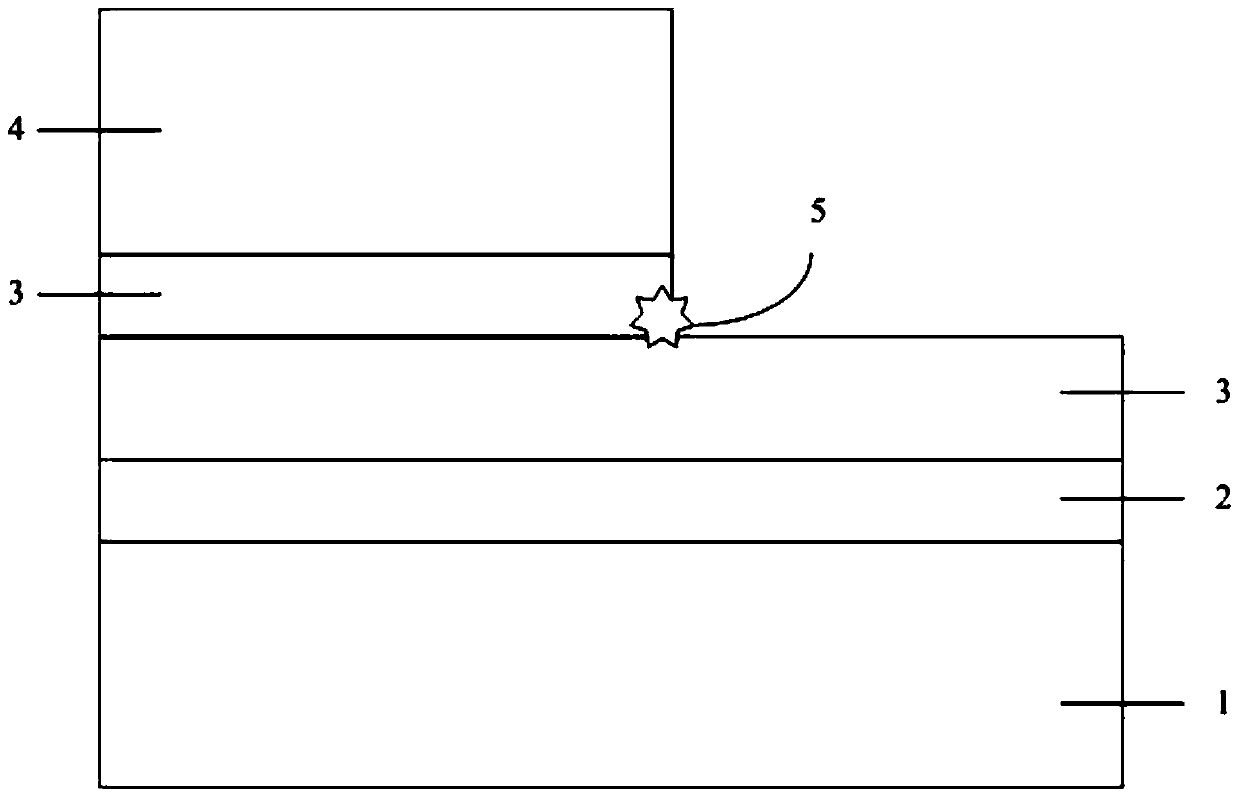

Image

Examples

Embodiment 1

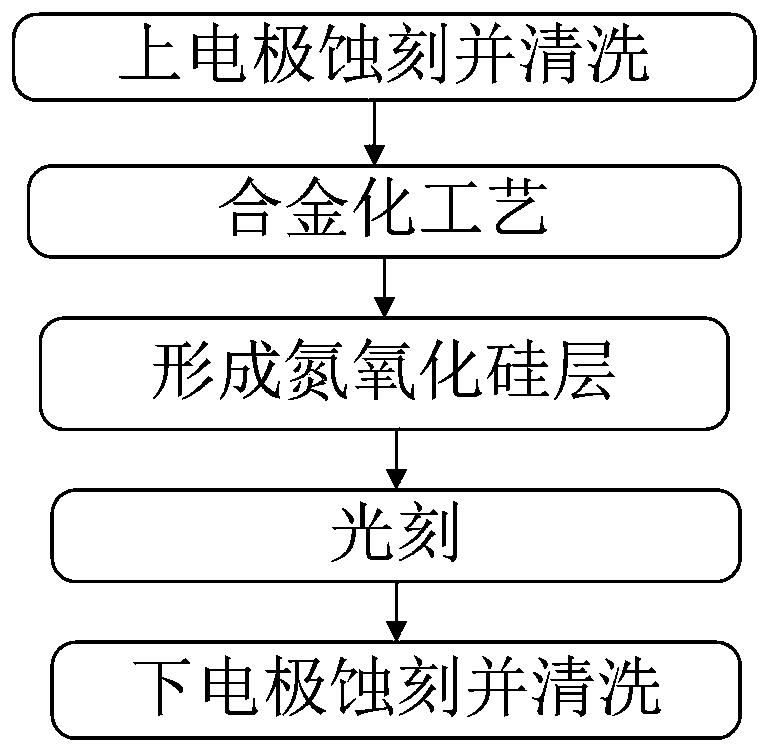

[0055] The process flow of a method for improving the performance of metal capacitor TDDB is as follows image 3 As shown: the metal capacitor includes an upper electrode, a lower electrode, and a dielectric layer between the upper electrode and the lower electrode, and the method includes:

[0056] Step 1: Etching and cleaning the upper electrode to expose part of the dielectric layer;

[0057] Step 2: Perform an alloying process to repair the exposed part of the dielectric layer;

[0058] Step 3: forming a silicon oxynitride layer, the silicon oxynitride layer covering the upper electrode and the exposed part of the dielectric layer;

[0059] Step 4: Perform photolithography;

[0060] Step 5: Etching and cleaning the lower electrode;

[0061] The alloying process uses hydrogen or nitrogen to act, the action temperature is 300-450 ° C, and the action time is greater than 20 minutes. After the upper electrode is etched, the exposed dielectric layer will have certain plasma ...

Embodiment 2

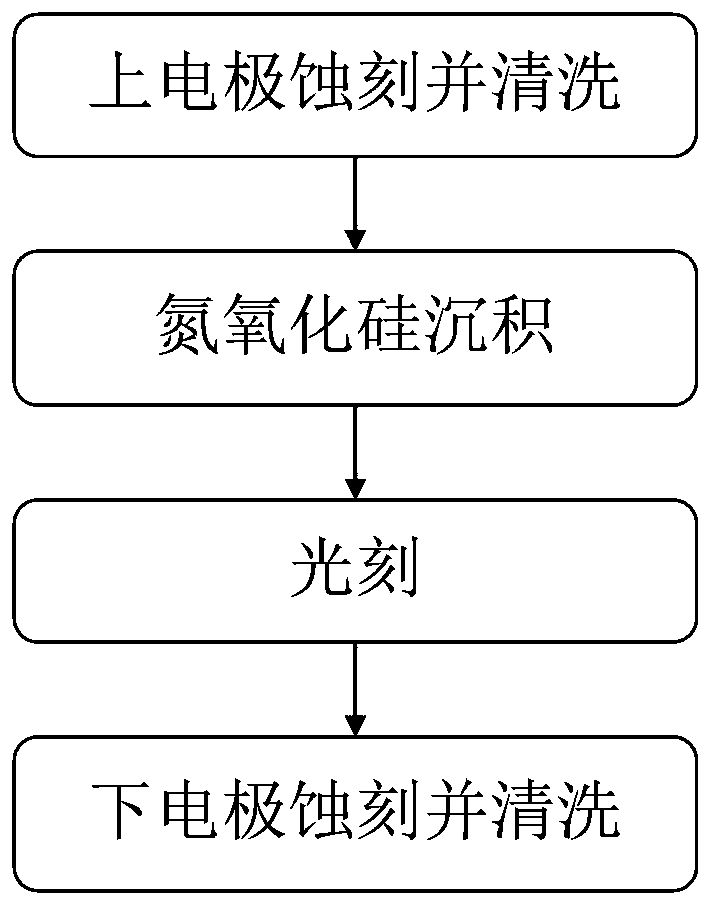

[0068] The process flow of a method for improving the performance of metal capacitor TDDB is as follows Figure 4 As shown: the metal capacitor includes an upper electrode, a lower electrode, and a dielectric layer between the upper electrode and the lower electrode, and the method includes:

[0069] Step 1: Etching and cleaning the upper electrode to expose the first part of the dielectric layer;

[0070] Step 2: forming a silicon oxynitride layer, the silicon oxynitride layer covering the upper electrode and the exposed first part of the dielectric layer;

[0071] Step 3: Perform photolithography;

[0072] Step 4: Etching and cleaning the lower electrode to expose the second part of the dielectric layer;

[0073] Step 5: Perform an alloying process to repair the exposed first part of the dielectric layer and the second part of the dielectric layer;

[0074] The alloying process utilizes hydrogen or nitrogen for action, the action temperature is 300-450° C., and the action...

Embodiment 3

[0082] A method for improving the performance of metal capacitor TDDB as Figure 5 Said, the metal capacitor includes an upper electrode, a lower electrode, and a dielectric layer between the upper electrode and the lower electrode, and the method includes:

[0083] Step 1: Etching and cleaning the upper electrode to expose the first part of the dielectric layer;

[0084] Step 2: Perform the first alloying process to repair the exposed first part of the dielectric layer;

[0085] Step 3: forming a silicon oxynitride layer, the silicon oxynitride layer covering the upper electrode and the exposed first part of the dielectric layer;

[0086] Step 4: Perform photolithography;

[0087] Step 5: Etching and cleaning the lower electrode to expose the second part of the dielectric layer;

[0088] Step 6: Perform the second alloying process to repair the exposed first part of the dielectric layer and the second part of the dielectric layer

[0089] The first alloying process and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com