Secondary fine restoration method for denture and preparation of restoration material

A repair method and denture technology, applied in the field of denture repair, can solve problems such as the separation of the soft lining material and the denture base, the deviation of the oral 3D three-dimensional parameters, and cannot be satisfied at the same time, and achieve low cost, balanced load-bearing capacity, and solve hygiene problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

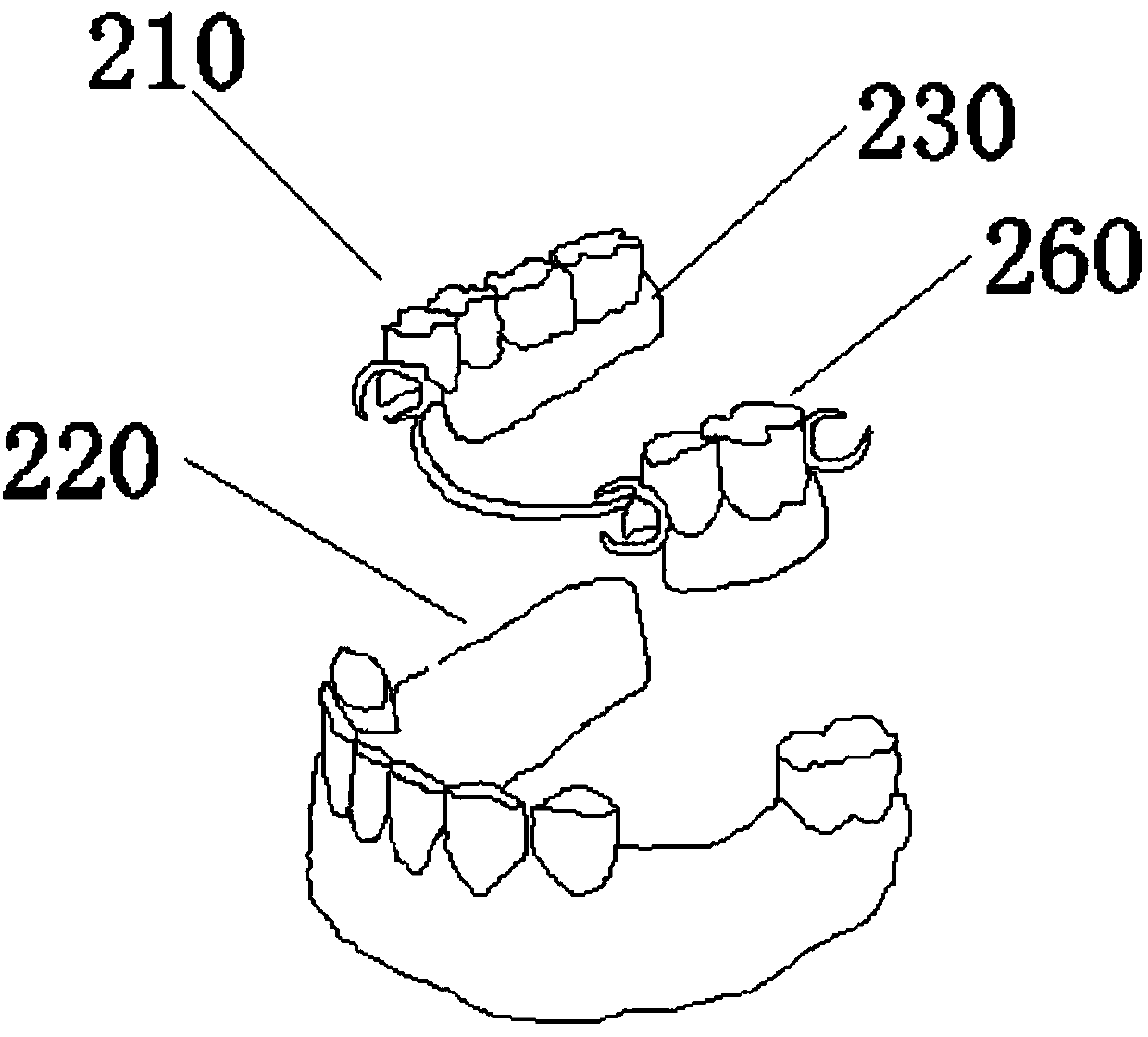

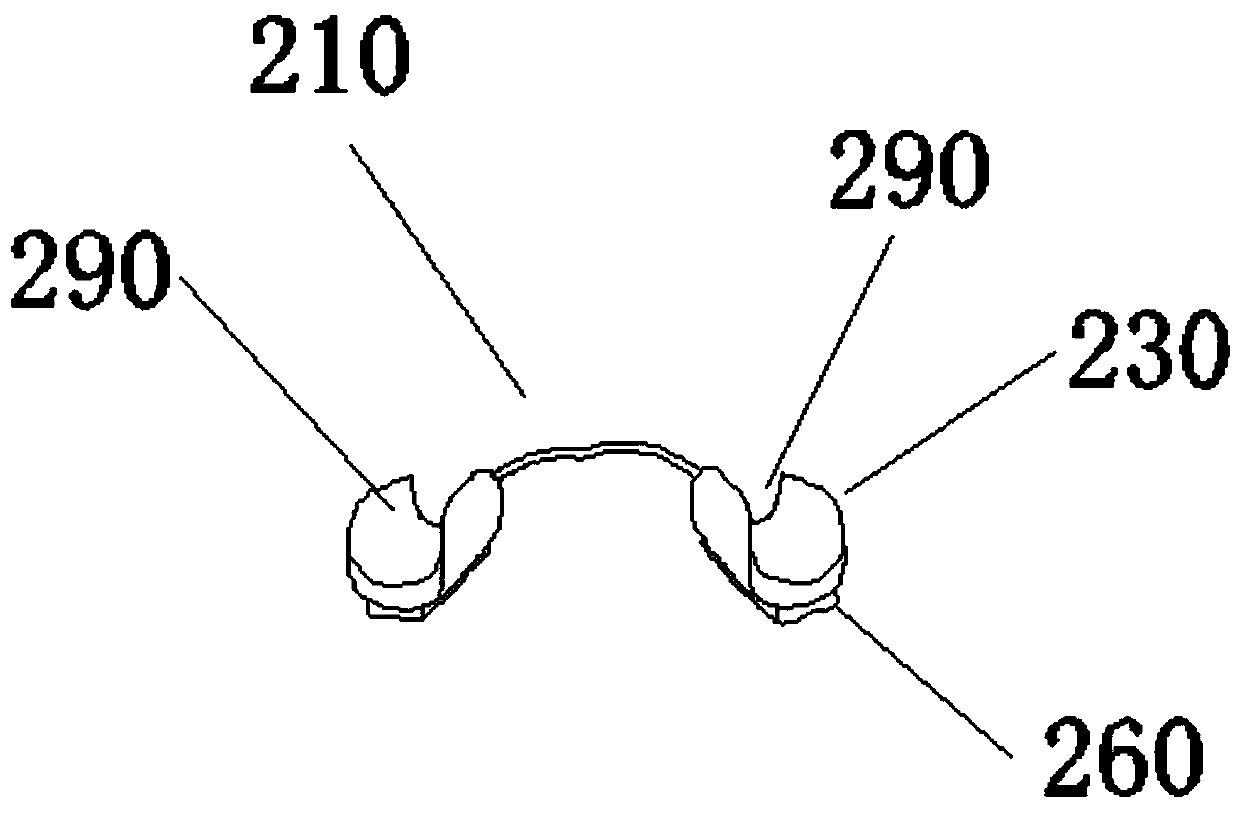

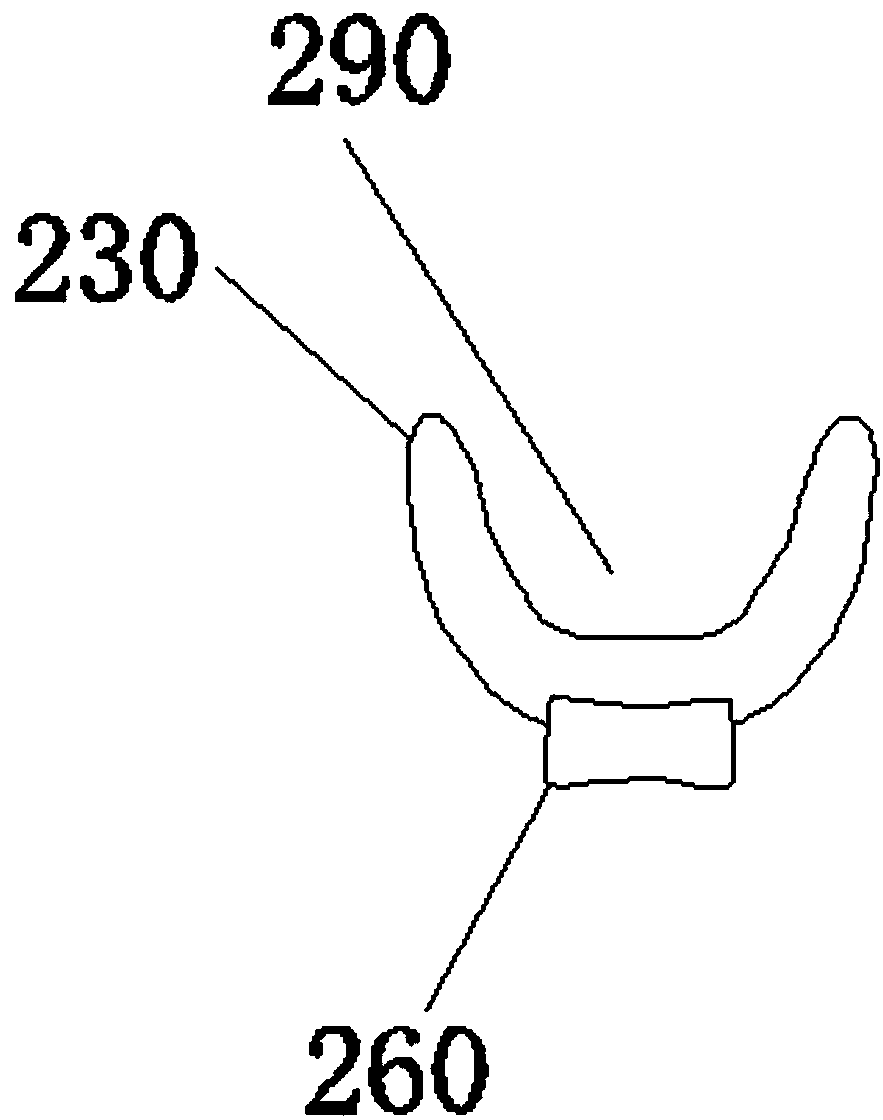

[0048] Example 1: Combining Figure 1-Figure 8 , Denture secondary fine repair method and the preparation of repair materials, and explain: the denture is repaired according to the existing materials and technology, and all technological processes such as adjustment are completed. After making the patient comfortable to wear for a period of time, carry out secondary filling and fine restoration: take out the removable denture 210, clean and dry it, and make a honeycomb hole layer 240 on the concave surface of the denture base 290. The resin is dissolved into a colloidal resin with a solvent, sodium chloride particles are added to the colloid, and the mixture of the colloid and sodium chloride is evenly reconciled, and a thin layer of the mixture of sodium chloride and the colloid is applied on the concave surface of the denture base at 290°. After the transition layer is solidified and dried, use sandpaper or a diamond file to grind the concave surface of the denture base, the...

Embodiment 2

[0050] Embodiment 2, combining Figure 9 The embodiment in which no drilling is arranged on the honeycomb hole layer: take out the movable denture 210, clean and dry, make the honeycomb hole layer 240 on the concave surface 290 of the denture base, the material is selected from the same or similar resin with the solubility parameter of the base resin, use The solvent is dissolved into colloidal resin, sodium chloride particles are added to the colloid, and the mixture of colloid and sodium chloride is evenly reconciled, and a thin layer of the mixture of sodium chloride and colloid is applied to the concave surface of the denture base. After solidification and drying, use Grinding the concave surface of the denture base with sandpaper or a diamond file, the purpose is to destroy the surface of the transition layer and expose the sodium chloride particles wrapped in colloid. Soak the polished denture in warm water until the sodium chloride is completely dissolved. Clean the den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com