Sulfurgypsum and phosphogypsum waste residue brick making process

A technology of phosphogypsum and sulfur gypsum, applied in the field of solid waste treatment, can solve problems such as no breakthrough progress, and achieve the effects of light weight, high strength and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

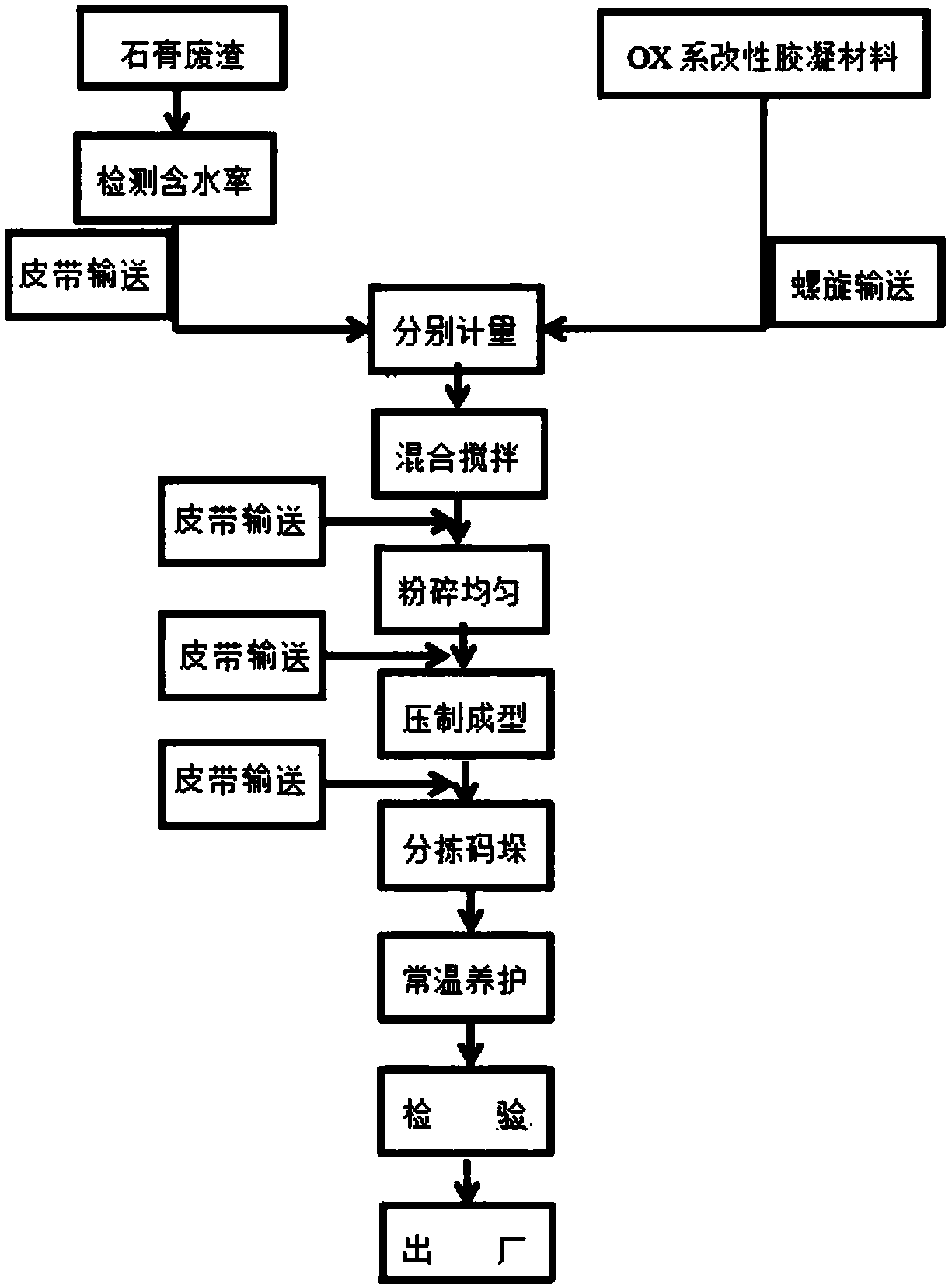

[0020] Such as figure 1 As shown, a brick making process of sulfur gypsum and phosphogypsum waste slag, the process flow is: Step 1: After the gypsum waste slag is tested for moisture content analysis, the system matches according to the input formula, and calculates the corresponding OX series modified cementitious material content Step 2: Gypsum waste residue is conveyed to the metering scale through a belt and the OX series modified cementitious materials are screwed to the metering scale for measurement respectively; Step 3: Gypsum waste residue and OX series modified cementitious materials are respectively measured and then transported to the mixer for measurement Mixing and stirring; Step 4: After mixing and stirring, it is conveyed by belt to the pulverizer to be pulverized into fine particles; Step 5: It is conveyed to the brick making machine through the belt, and the brick making machine is pressed to shape and sorted by the automatic control manipulator; Step 6: By T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com