Ultra-fine silica material and its application for significantly promoting hair color

An ultra-fine silicon dioxide and silicon dioxide technology, which is applied to ceramic inkjet printing additives and their application fields, can solve the problems of limited effect of color development, limited effect of color development, etc., and achieve good color development effect, Good hair color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

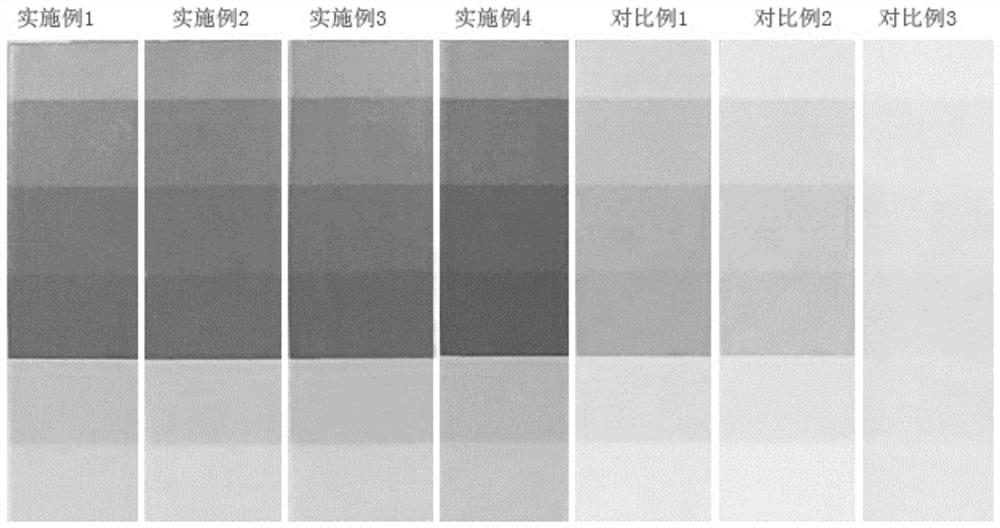

Image

Examples

preparation example Construction

[0032] As a further improvement of the above-mentioned silicon dioxide material with a color-aiding effect, its preparation method includes the following steps:

[0033] 1) Wash away the impurity salt on the surface of the silica substrate as required;

[0034] 2) adjusting the pH of the silica matrix to be 6-8, preferably 6.5-7.5;

[0035] 3) adding a color-assisting salt with a color-aiding effect to the silica matrix, the color-assisting salt is selected from at least one of water-soluble metal salts and boron-containing salts, and fully stirred evenly;

[0036] 4) filtering, drying and crushing to obtain silica material.

[0037] Due to the preparation process of the silica matrix, it is inevitable that some impurity salts will be contaminated. In order to avoid the reaction of impurity salts and color-assisting salts and affect the final color-aiding effect of the material, it is necessary to purify the silica matrix to avoid this phenomenon. If the silica matrix used ...

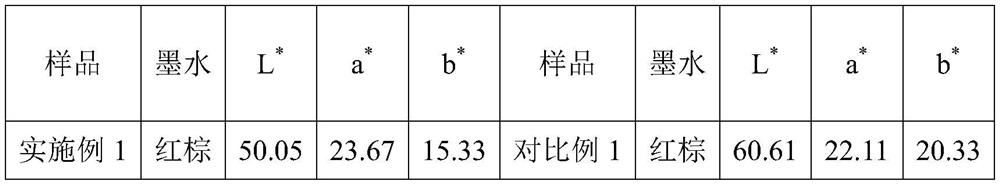

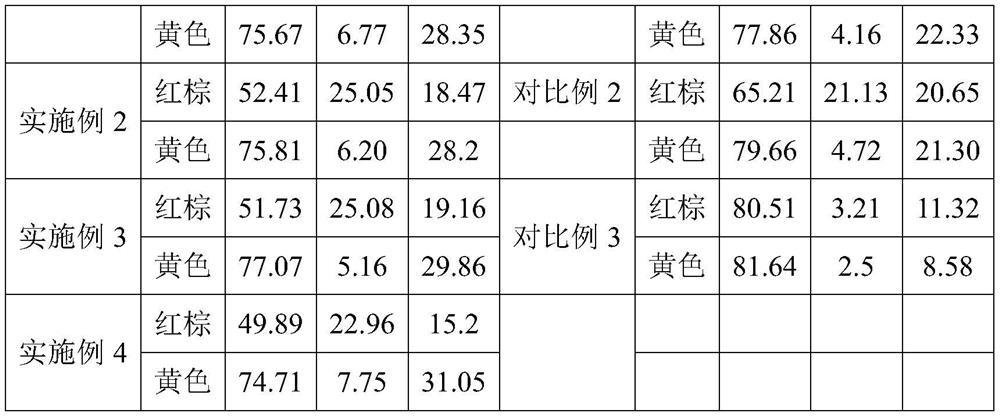

Embodiment 1

[0045] An ultra-fine silica material with significant hair coloring effect, the matrix is composed of fumed silica slurry, the primary particle size of silica in the matrix is 7nm, and the specific surface area is 380m 2 / g, the stacked pore diameter is 5-20nm. The acid-base regulator is a sulfuric acid solution, the potassium chloride solution is selected as the color-promoting ion solution, the addition amount is 2.0%, and the particle size of the jet mill is 15 μm. When applied, its mass proportion in the surface glaze of ceramic tiles or the dry basis of fabrics is 3%.

[0046] The preparation method is as follows: (1) adjusting the pH value of the ultrafine silica matrix to about 7 with an acid-base regulator; (2) adding a color-promoting ion solution to the neutral ultrafine silica matrix in proportion, Stir well; (3) filter and dry; (4) jet mill and crush.

[0047]The method of use is: add the ultra-fine silica material with a significant color-promoting effect in...

Embodiment 2

[0049] An ultra-fine silica material with significant hair coloring effect, the matrix is composed of silica airgel slurry, the primary particle size of silica in the matrix is 5nm, and the specific surface area is 600m 2 / g, the stacked pore diameter is 10-20nm. The acid-base regulator is ammonia solution, and potassium chloride and magnesium chloride solutions are selected as the color-promoting ion solution, the addition amount is 2.0%, and the particle size of the jet mill is 20 μm. When applied, its mass proportion in the glaze of the ceramic tile or the dry basis of the fabric is 2%.

[0050] The preparation method and usage method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com