Preparation method of stainless steel pipe for sealing ring with high resilience

A technology of stainless steel pipe and high resilience, which is applied in the preparation process of 1Cr18Ni9Ti seamless thin-diameter steel pipe for sealing ring and the field of preparation of stainless steel pipe for sealing ring. Sensitivity and other issues, to achieve excellent rebound performance, ensure comprehensive performance, and reasonable compression load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

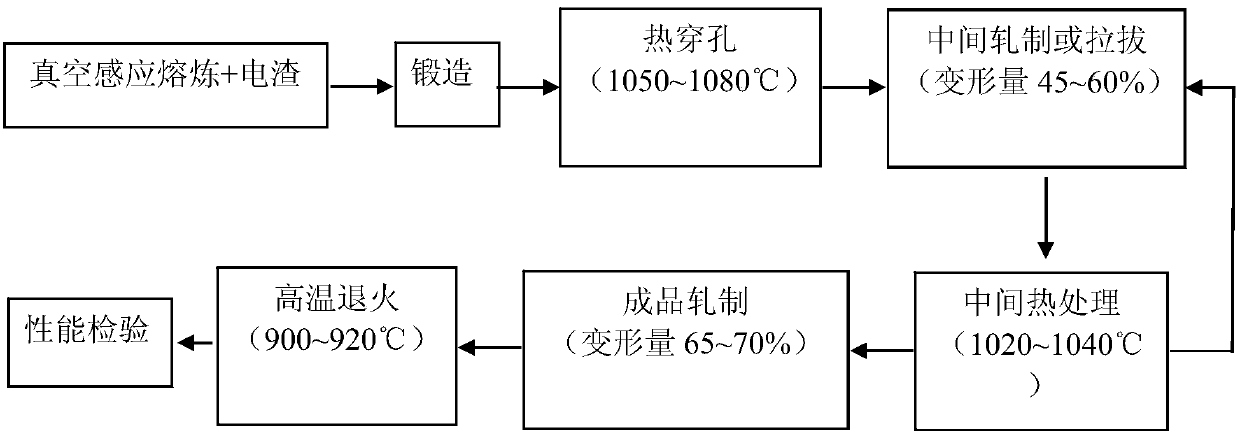

[0028] like figure 1 Shown is the preparation process flow diagram of the stainless steel tube for sealing ring with high resilience performance of the present invention, as can be seen from the figure The preparation method for the stainless steel tube for sealing ring with high resilience performance of the present invention comprises the following steps:

[0029] (1) The method of vacuum induction melting + electroslag is used to smelt steel ingots, and the ingots are forged into steel rods. The chemical composition range is in accordance with the requirements of GJB2294-95;

[0030] (2) Hot perforating the steel rod at 1050-1080°C to obtain a stainless steel tube blank;

[0031] (3), the stainless steel tube blank is carried out N times intermediate treatment, obtains stainless steel pipe transition piece; Said intermediate treatment comprises intermediate rolling or drawing, and intermediate heat treatment, wherein the deformation of each intermediate rolling or drawing i...

Embodiment 1

[0039] 1Cr18Ni9Ti austenitic stainless steel was prepared by vacuum induction + electroslag process, and 1Cr18Ni9Ti steel rod was prepared after forging. The chemical composition is shown in Table 1.

[0040] Chemical composition of the alloy in table 1 (wt.%)

[0041] C

Mn

Si

P

S

Ni

Cr

Ti

Fe

0.039

0.67

0.28

0.010

0.004

10.10

17.62

0.51

Remain

[0042] The specific production process such as figure 1 , the actual operation steps are as follows:

[0043] (1) Hot piercing is performed on the steel bar at 1060°C, and the size after piercing is Φ38×5mm.

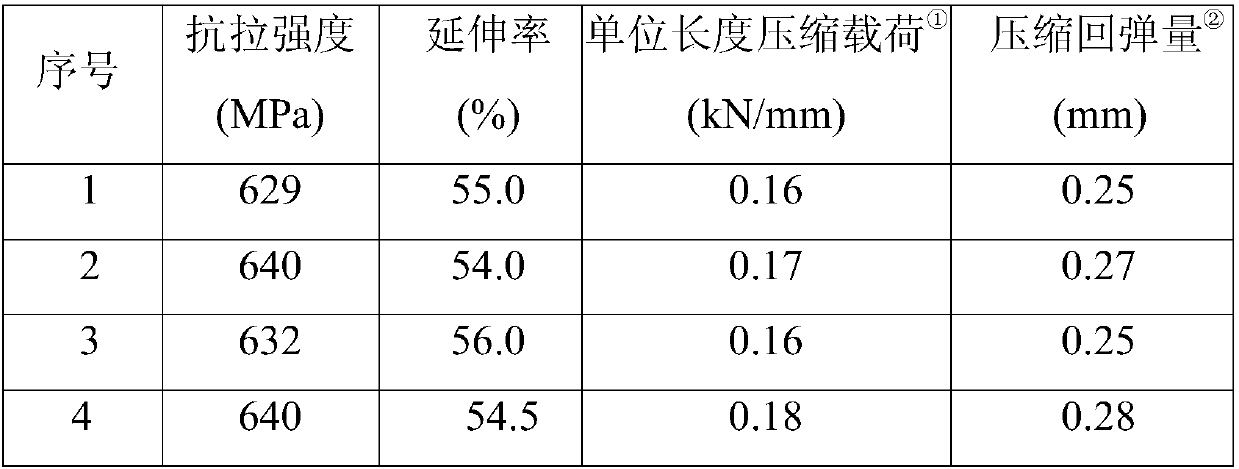

[0044] (2) Perform intermediate rolling or drawing repeatedly on the tube blank after hot piercing, and perform intermediate heat treatment. The number of repetitions is 6 times, the amount of intermediate rolling or drawing deformation is controlled at 48%, and the intermediate heat treatment temperature is controlled at 1025°C; the size of the tube blan...

Embodiment 2

[0054] Using the same chemical composition and the same hot piercing process as in Example 1, a tube blank with a diameter of 38×5 mm was obtained. According to the process figure 1 Do the following:

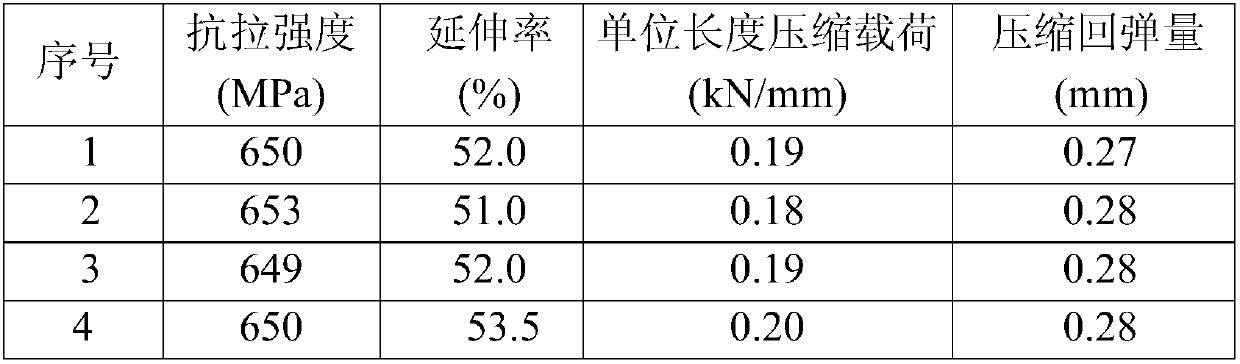

[0055] (1) Perform intermediate rolling or drawing repeatedly on the tube blank after hot piercing, and perform intermediate heat treatment. In this embodiment, the intermediate process adopts multi-pass rolling deformation, and part of the passes adopts drawing deformation. The amount of rolling and drawing deformation are both controlled at 50%, the intermediate heat treatment temperature is 1030 °C, and the tube blank size of the steel pipe transition piece is controlled as Φ5.2×1mm.

[0056] (2) Complete the finished product rolling of the steel pipe transition piece, and the rolling deformation is controlled at 70%;

[0057] (3) Perform annealing heat treatment at 920° C. on the finished rolled steel pipe; the treatment time is 20 minutes, and the obtained steel pipe has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com