Biomass solid fuel boiler for electric power generation

A solid fuel, biomass technology, applied in the field of mechanical thermal energy, can solve the problems of loose land occupation, inconvenient installation and maintenance, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

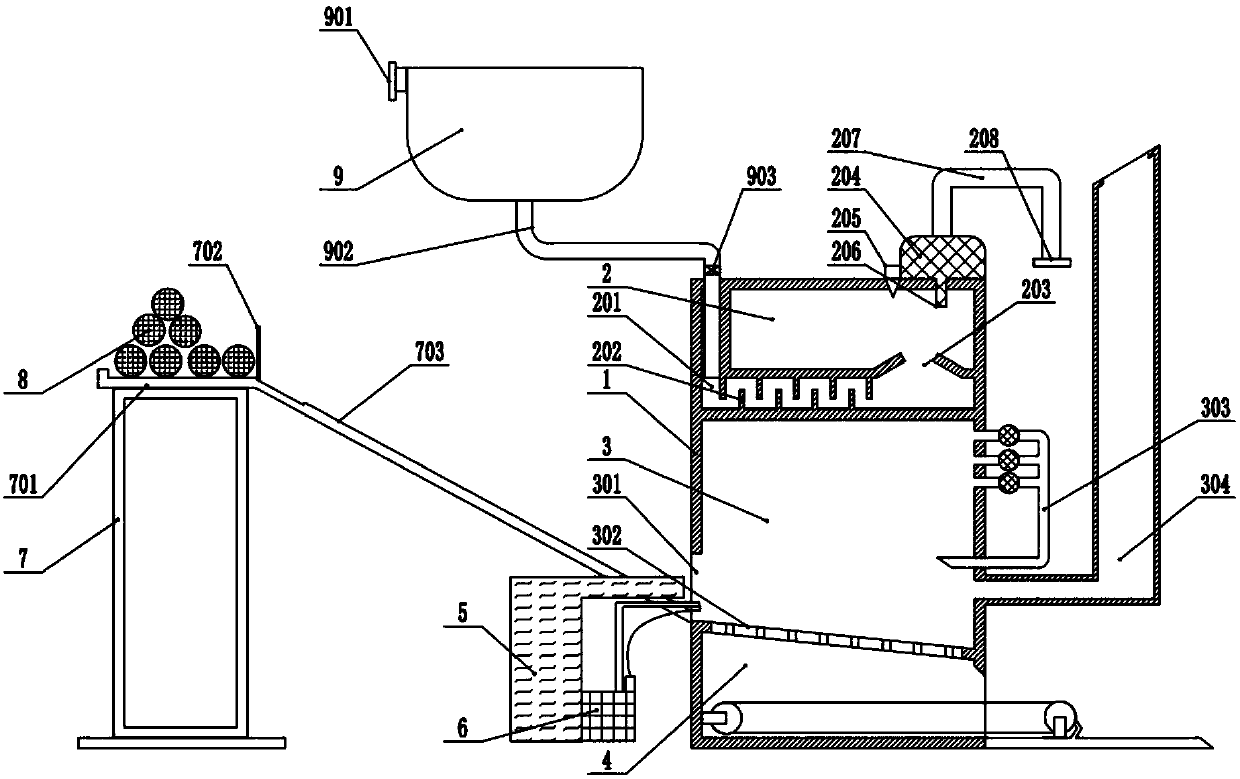

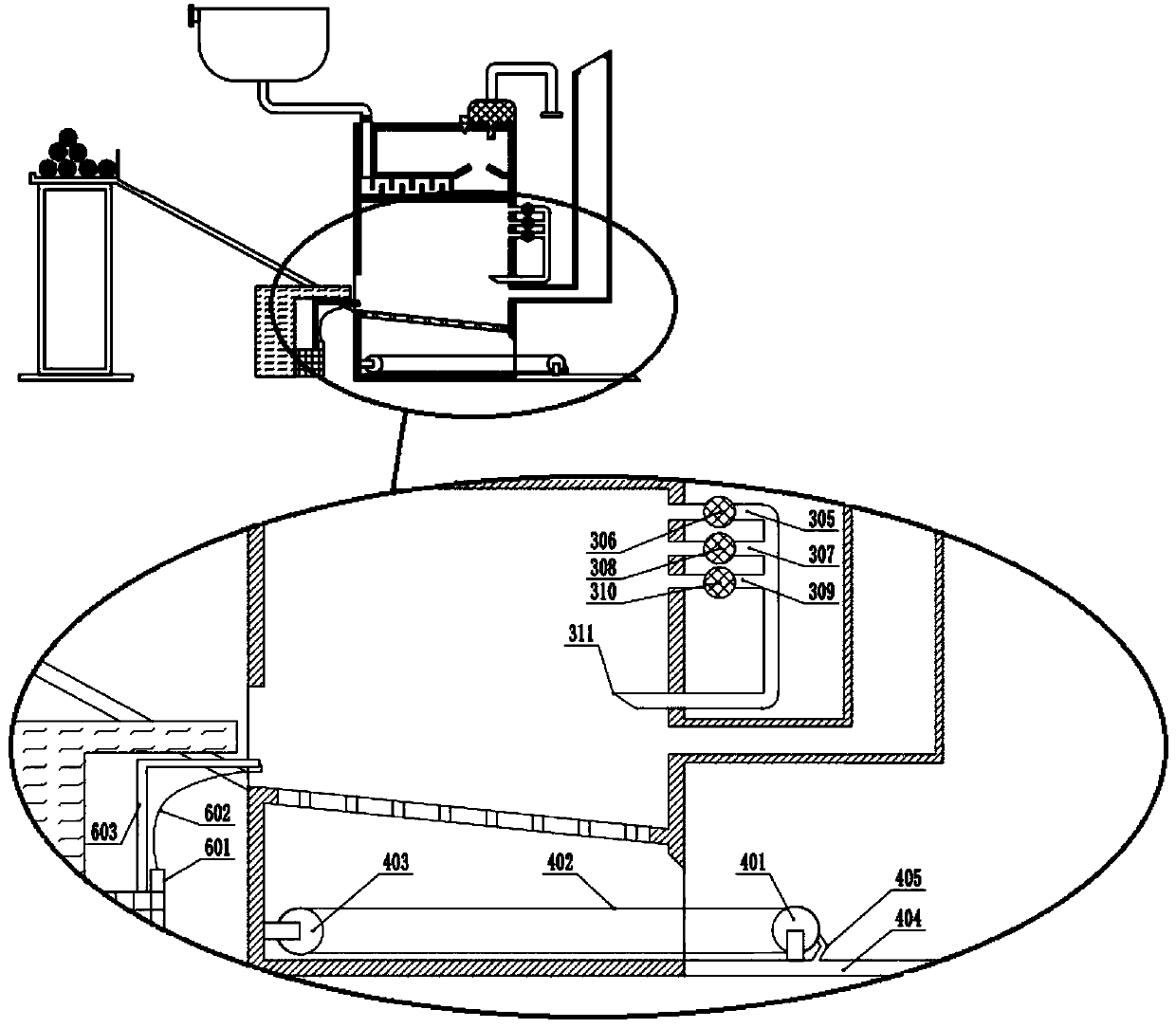

[0022] Combine below Figure 1-2The structure of the biomass solid fuel boiler for electric power generation of the present invention is described in detail. A biomass solid fuel boiler for electric power generation, comprising a boiler 1, the boiler 1 is composed of a water chamber 2, a combustion chamber 3 and an ash chamber 4, a feed port 301 is provided on one side of the combustion chamber 3, and the combustion chamber 3. A leaking screen 302 is installed at the bottom, and a smoke return pipe 303 is installed on the other side of the combustion chamber 3. The upper part of the smoke return pipe 303 is divided into a first smoke pipe 305, a second smoke pipe 307 and a third smoke pipe from top to bottom. 3093 parts, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com