Fluidization feeding device for fluidized bed boiler

A fluidized bed boiler and feeding device technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of flue gas or ash leakage, reduce boiler and feeding parts air leakage, etc., to reduce CO and other pollution Formation of substances, prevention of expansion and deformation, and improvement of economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Example.

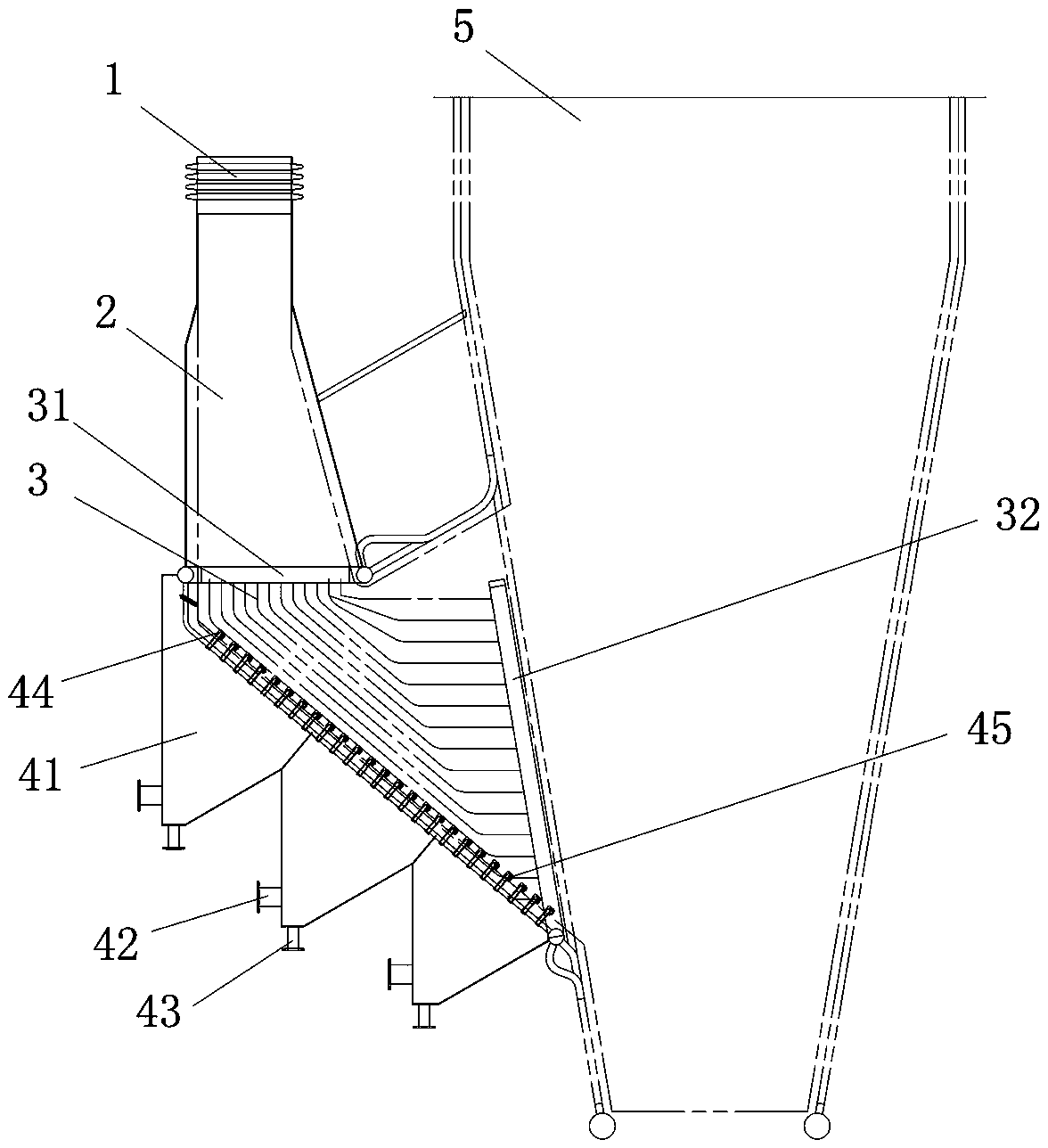

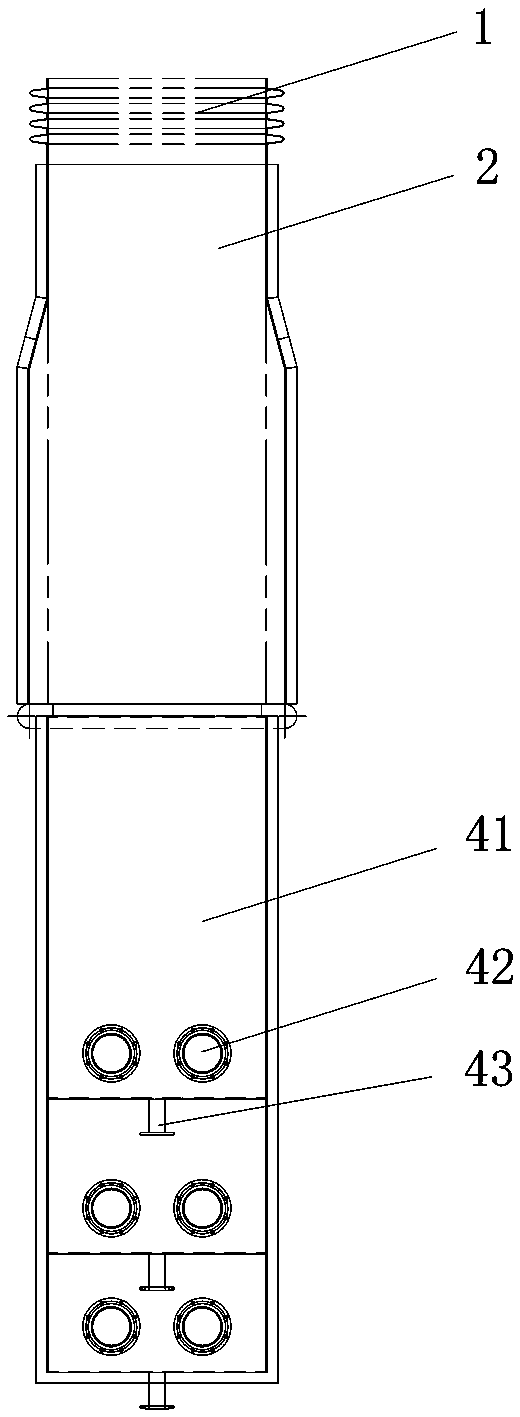

[0016] Such as Figure 1-2 As shown, this embodiment includes an expansion joint 1, a feeding material connecting tank 2, a feeding material chamber 3 and a fluidization device, wherein the inner walls of the feeding material connecting tank 2 and the feeding material chamber 3 are coated with refractory castables. Coating refractory castables on the inner walls of the feeding connecting tank 2 and the feeding chamber 3 can improve the heat resistance of the feeding connecting tank 2 and the feeding chamber 3, and extend the feeding connecting tank 2 and the feeding chamber 3 service life.

[0017] The upper end of the expansion joint 1 is connected with the drop pipe, and the lower end is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com