Dynamic monitoring test apparatus for propagation of fractures from triaxial pulse loading hydraulic fracturing

A technology of hydraulic fracturing and crack expansion, applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc. It can solve the problems that the monitoring system cannot be unified and coordinated, and crack expansion cannot be monitored in three dimensions in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

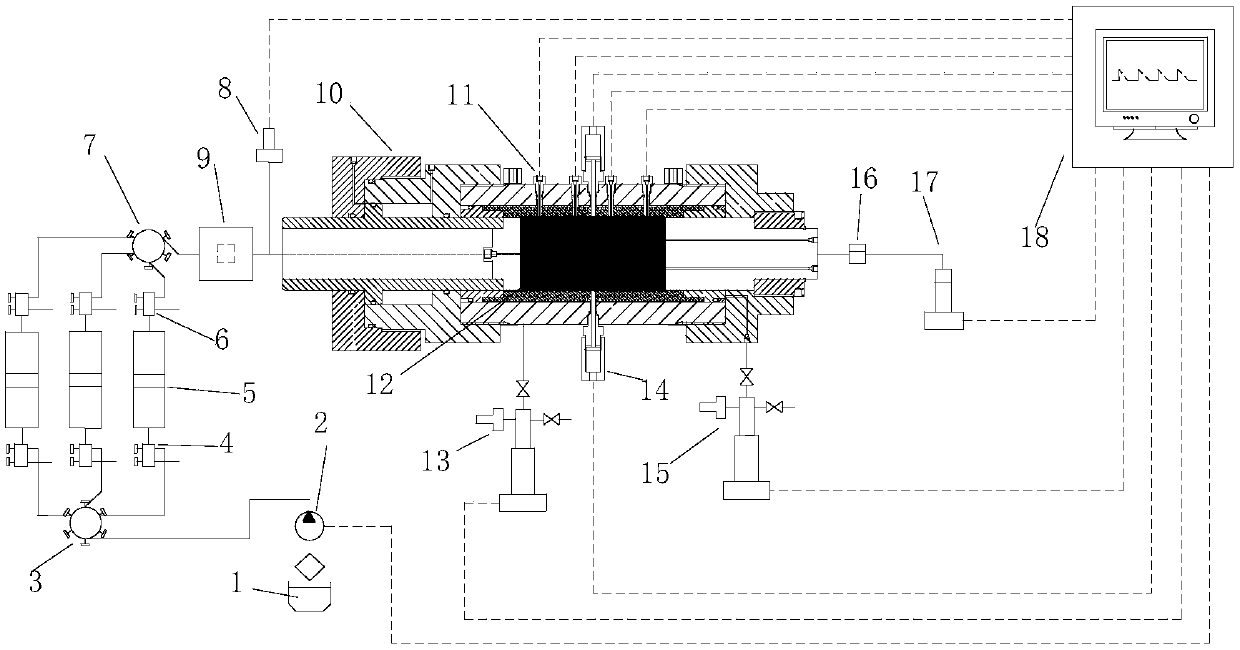

[0030] refer to figure 1, the pulse hydraulic injection system consists of a high-pressure pump 2, a first multi-way valve 3, a first on-off valve 4, an intermediate container 5, a second on-off valve 6, a second multi-way valve 7, and an inlet pressure sensor 8. Liquid control system and pulse generator 9 components. The high-pressure pump 2 can adjust the liquid injection pressure and the liquid injection flow rate, the liquid injection pressure is 0-40MPa, and the flow rate adjustment range is 0.01-9.99mL / s. Using the intermediate container 5 to displace the fracturing fluid can not only inject fracturing fluids of different systems at the same time, but also prevent the high-pressure pump from running a fracturing fluid system with high viscosity and sand c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com