CXP modular structure

A module structure and metal block technology, which is applied in light guides, optics, instruments, etc., can solve the problems of poor module adaptability to the environment, module performance degradation, and low product qualification rate, so as to prevent performance degradation, improve product reliability, and increase The effect of cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

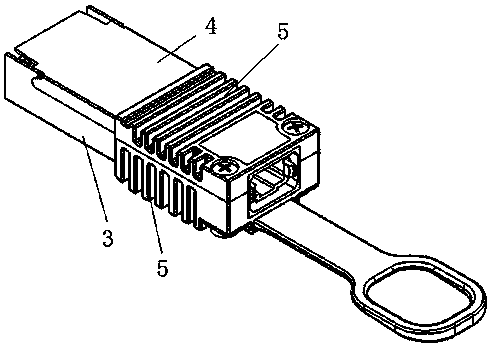

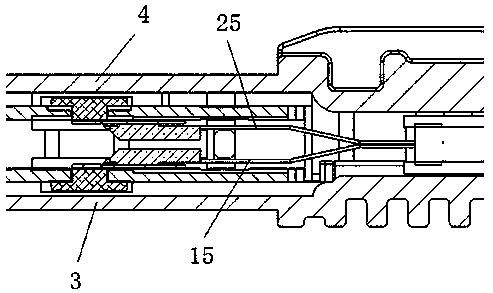

[0018] see Figure 1 to Figure 4 , a CXP module structure, including an upper shell 4 and a lower shell 3, the upper shell 4 and the lower shell 3 are locked by screws, and the optical port ends of the upper shell 4 and the lower shell 3 are blade-type structures 5, increasing the entire shell heat dissipation area.

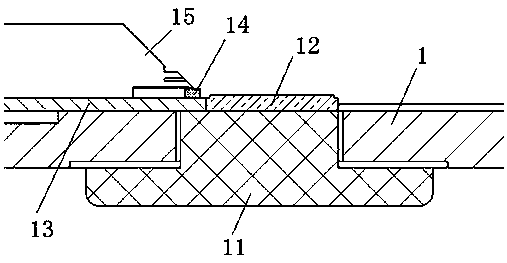

[0019] The lower shell 3 is provided with a transmitting terminal printed circuit board 1, and the transmitting terminal printed circuit board 1 is provided with a transmitting terminal metal block mounting hole (not shown in the figure), and a transmitting terminal metal block mounting hole is provided with a transmitting terminal metal block 11. The end metal block 11 is a "convex"-shaped structure, and the top of the transmitting end metal block 11 is a raised portion. A driver chip 12 is pasted on the surface of the top surface of the body. Specifically, the driver chip 12 is pasted with the metal block 11 of the transmitting end through thermal conductive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com