Tablet bottling machine

A bottling machine and tablet technology, applied in packaging, sealing machine, package protection and other directions, can solve the problems of complex structure of automatic bottling machine, difficult to popularize and apply automatic equipment, and high manufacturing cost, and achieve simple structure and high manufacturing cost. Low, labor-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

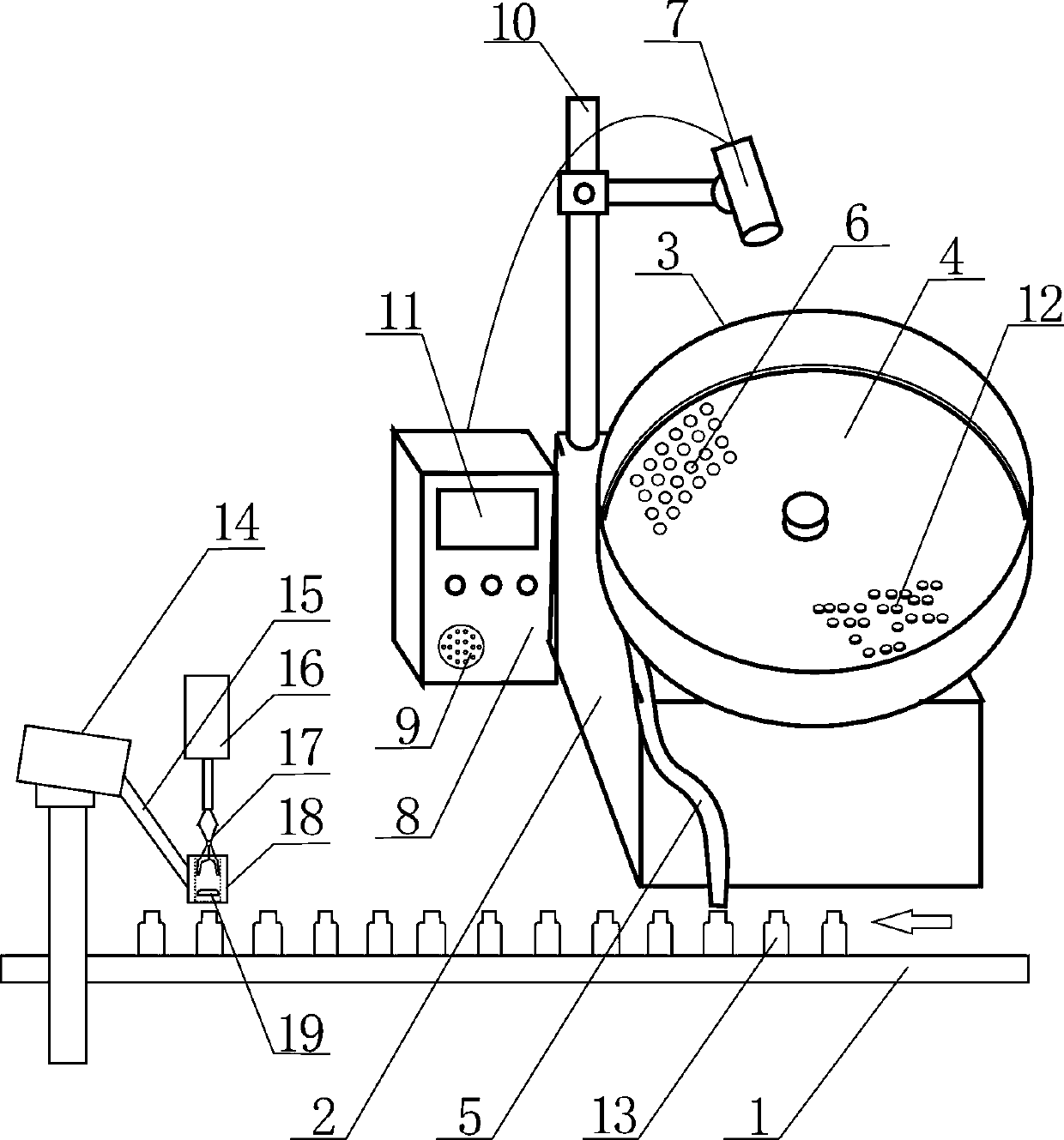

[0016] Such as figure 1 As shown, the tablet bottling machine includes an intermittent drug bottle conveyor belt 1, a tablet conveyor, a vibrating table 2 and a monitoring device for the number of missing tablets, wherein each tablet conveyor is mainly composed of a circular material barrel 3 and a turntable 4 It is composed of a tablet outlet pipe 5, and the circular material barrel 3 is installed obliquely on the vibrating table 2. The upper end of the tablet outlet pipe 5 communicates with the discharge port at the bottom of the circular material barrel 3, and the lower end of the tablet outlet pipe 5 is set at the intermittent Above the bottle conveyor belt 1, the turntable 4 is set in the circular material barrel 3 and is parallel to the bottom surface of the circular material barrel 3, and the gap between the turntable 4 and the barrel wall and the bottom surface of the circular material barrel 3 is smaller than that of the tablet. Diameter, the surface of the turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com