Ganoderma mycelium fermentation liquor with high ganoderma polysaccharide content and method for preparing ganoderma mycelium fermentation liquor

A technology of Ganoderma lucidum polysaccharide and Ganoderma lucidum mycelium, which is applied in fermentation, fungi and other directions, can solve the problems of long production cycle, high cost, differences in active ingredient composition and content, etc., and achieves the effect of less possibility of pollution and short fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

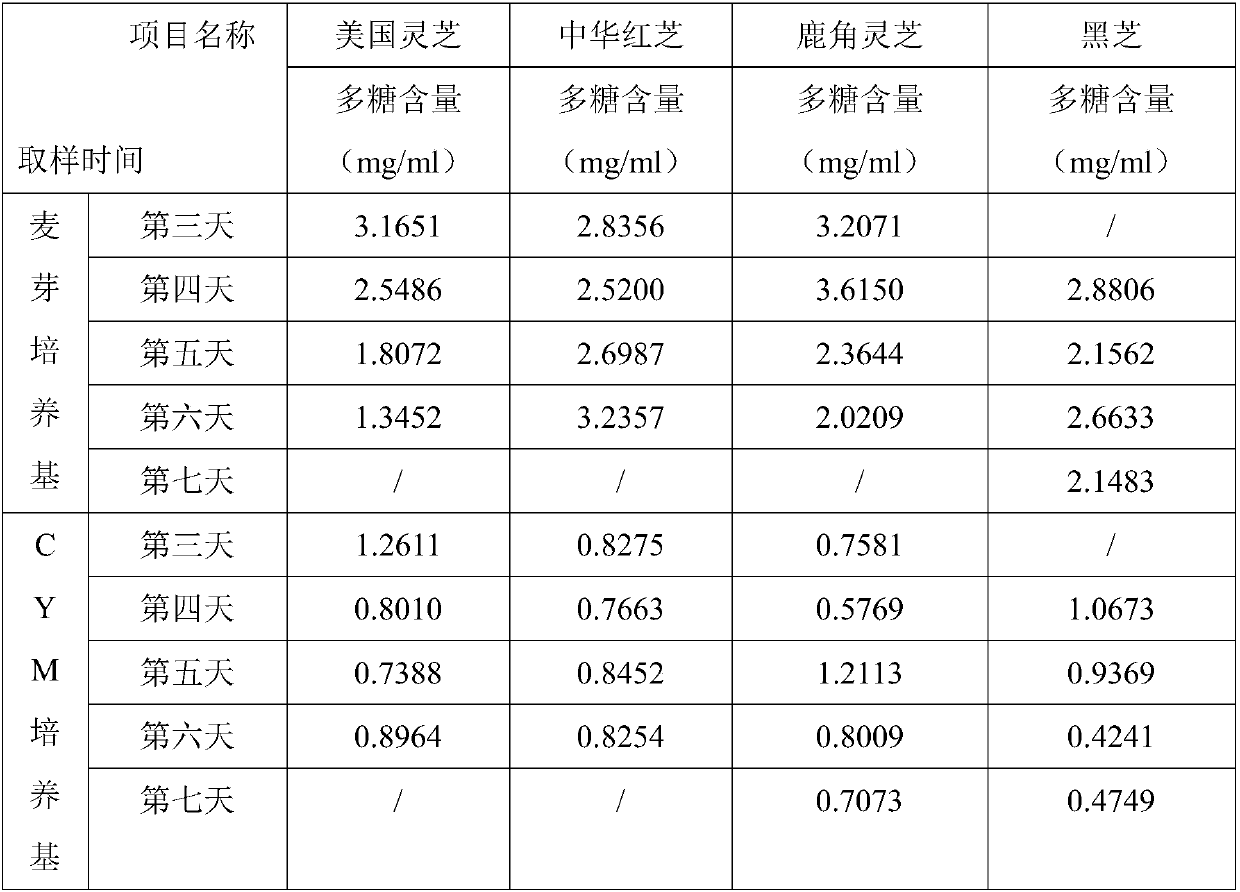

[0018] The invention relates to a preparation method of a ganoderma lucidum mycelia fermentation liquid with high ganoderma polysaccharide content, comprising:

[0019] The ganoderma lucidum strain is cultured in inclined test tubes to obtain mycelium blocks, and the mycelium blocks are inoculated on plate medium for mycelial culture, and then transferred to malt medium for liquid fermentation culture at 25-29°C for 3-7 days.

[0020] Preferably, when the Ganoderma lucidum strain is Ganoderma lucidum, the culture time is 3 days; when the Ganoderma lucidum strain is Ganoderma lucidum, the culture time is 4 days; days; when the ganoderma lucidum strain is Heizhi, the culture time is 4 days.

[0021] The method adopts a mycelium liquid fermentation method, the ganoderma lucidum polysaccharide content is high, the fermentation method is more environmentally friendly, the cost is lower, the required time is shorter, the fermentation method is simple, easy to operate, suitable for l...

Embodiment

[0043] 1. Preparation of medium and solution

[0044] Plate medium: MEA (Malt Extract Ager): malt extract 30g, soybean peptone 3g, agar malt extract 3w / v%, soybean peptone 0.3w / v%, agar 1.5w / v%, h 2 O 1L to constant volume, pH 5.6, sterilized at 121°C for 15 minutes.

[0045] Malt medium: malt extract powder 2w / v%, glucose 2w / v%, peptone 0.1w / v%, yeast extract 0.1w / v%, H 2 O 1L to constant volume, sterilized at 115°C for 20min.

[0046] CYM medium: glucose 20g, peptone 2g, yeast powder 2g, MgSO 4 ﹒ 7H 2 O0.5g, K 2 HPO 4 1g, KH 2 PO 4 0.46g, H 2 O 1L.

[0047] 2. Liquid fermentation culture method of Ganoderma lucidum strain

[0048] After each strain was cultured in a slant test tube, take a piece of 1cm 2 The mycelium block was inoculated into the plate medium, and cultured at 30°C for 7 days. Then take 1.5cm from the plate medium 2 Inoculate into malt culture medium (300ml Erlenmeyer flask, liquid volume 100ml) and CYM medium respectively, cultivate at 27°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com