Efficient separation type biomass particle combustor

A biomass particle separation technology, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problem of low combustion efficiency of separated and clean biomass particle burners, and achieve simple and effective screening of ash. The effect of high transportation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

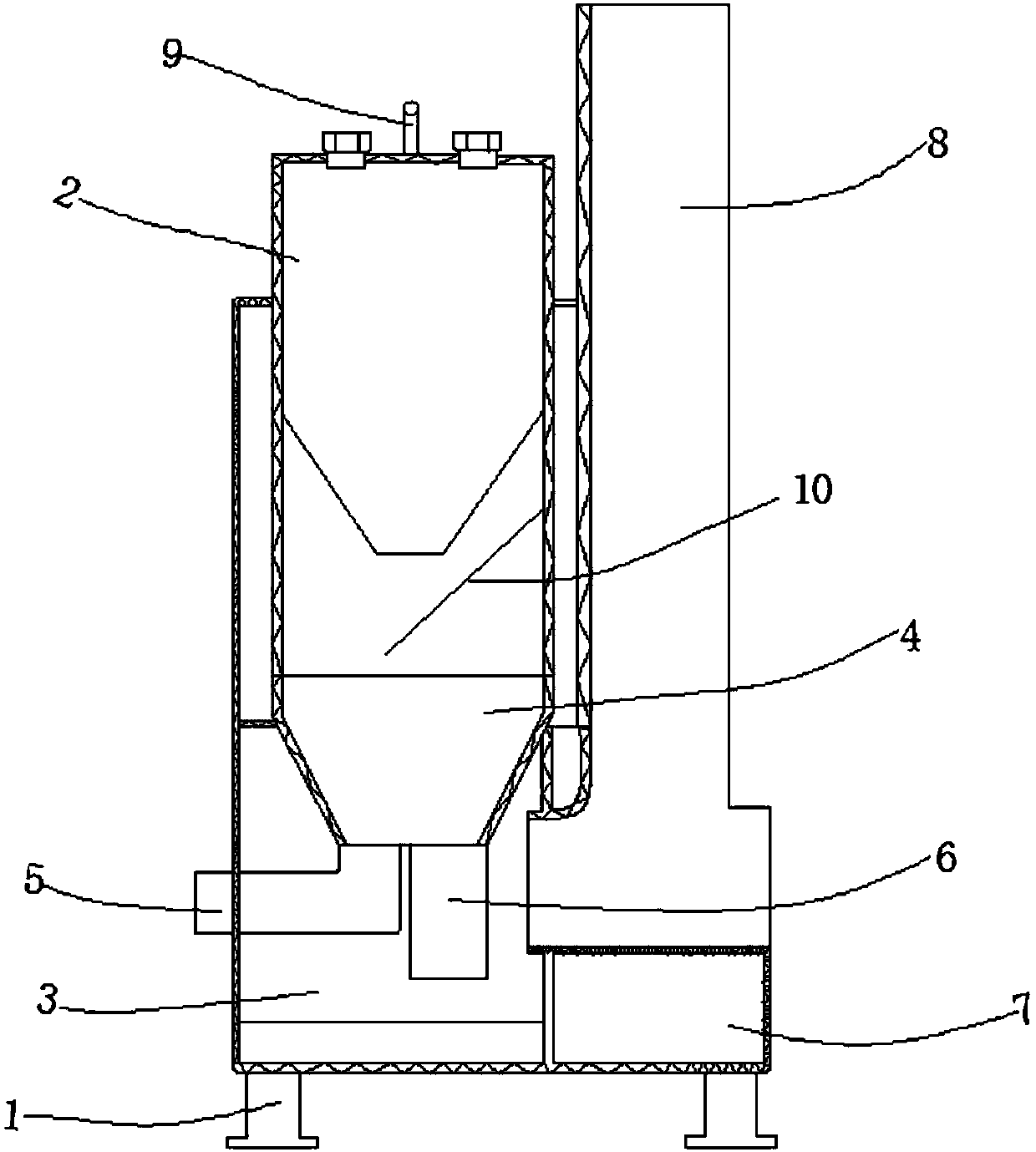

[0026] This embodiment provides a high-efficiency separated biomass pellet burner, including: a frame 1, a first combustion chamber 2 arranged on the frame 1, a second combustion chamber 3, and a first combustion chamber 2 and a second combustion chamber for discharging The flue 8 of the flue gas of the second combustion chamber 3, the external equipment 7 that fits the flue 8 and the second combustion chamber 3 are characterized in that it also includes a collection device 10 arranged in the first combustion chamber 2 and The distributing mechanism 4 used for the separation of ash and coking substances is arranged between the first combustion chamber 2 and the second combustion chamber 3. The distributing mechanism 4 includes an ash outlet 5 and a coking substance outlet 6. The coking substance outlet 6 is connected to the second coking substance outlet. The two combustion chambers 3 are connected, and the burned material of the first combustion chamber 2 first enters the side...

Embodiment 2

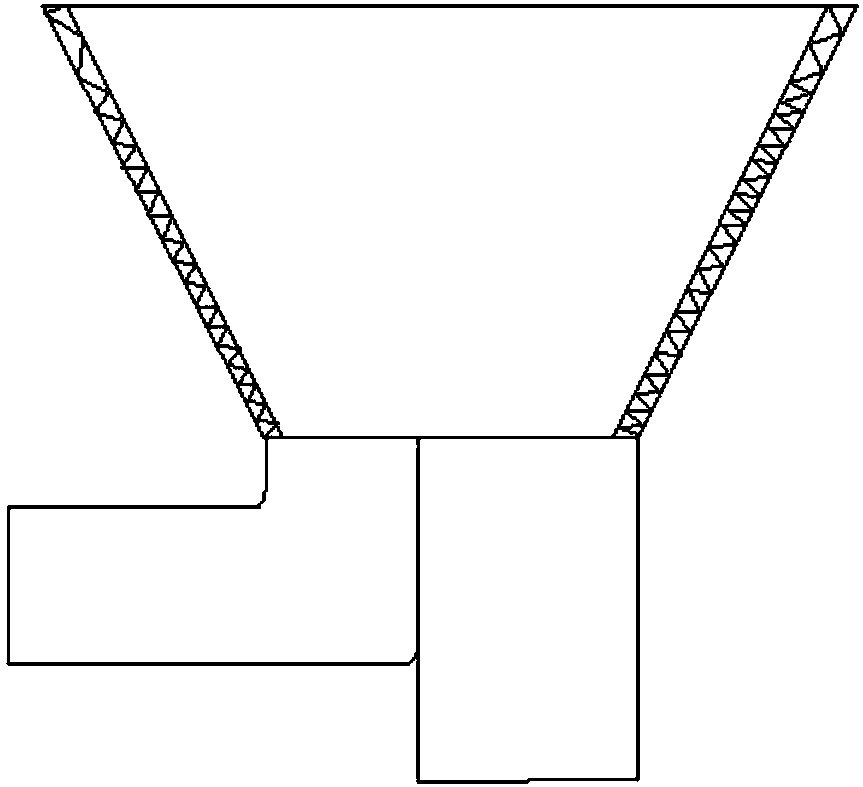

[0029] On the basis of Embodiment 1, the ash screening area 4-5 is provided with ash holes through which the ash goes out, and the coked matter in the first combustion chamber 2 enters the second combustion chamber 3 through the coked matter discharge area 4-6.

[0030] This embodiment provides a simple ash screening area 4-5 structure, but here as long as the ash after the combustion of the first combustion chamber 2 can be separated, the diameter of the ash is generally much smaller than the diameter of the coked material. Therefore, this embodiment uses this rule to directly set the gray matter screening area 4-5 into a network structure, wherein the diameter of the gray matter hole is kept similar to the diameter of the gray matter.

Embodiment 3

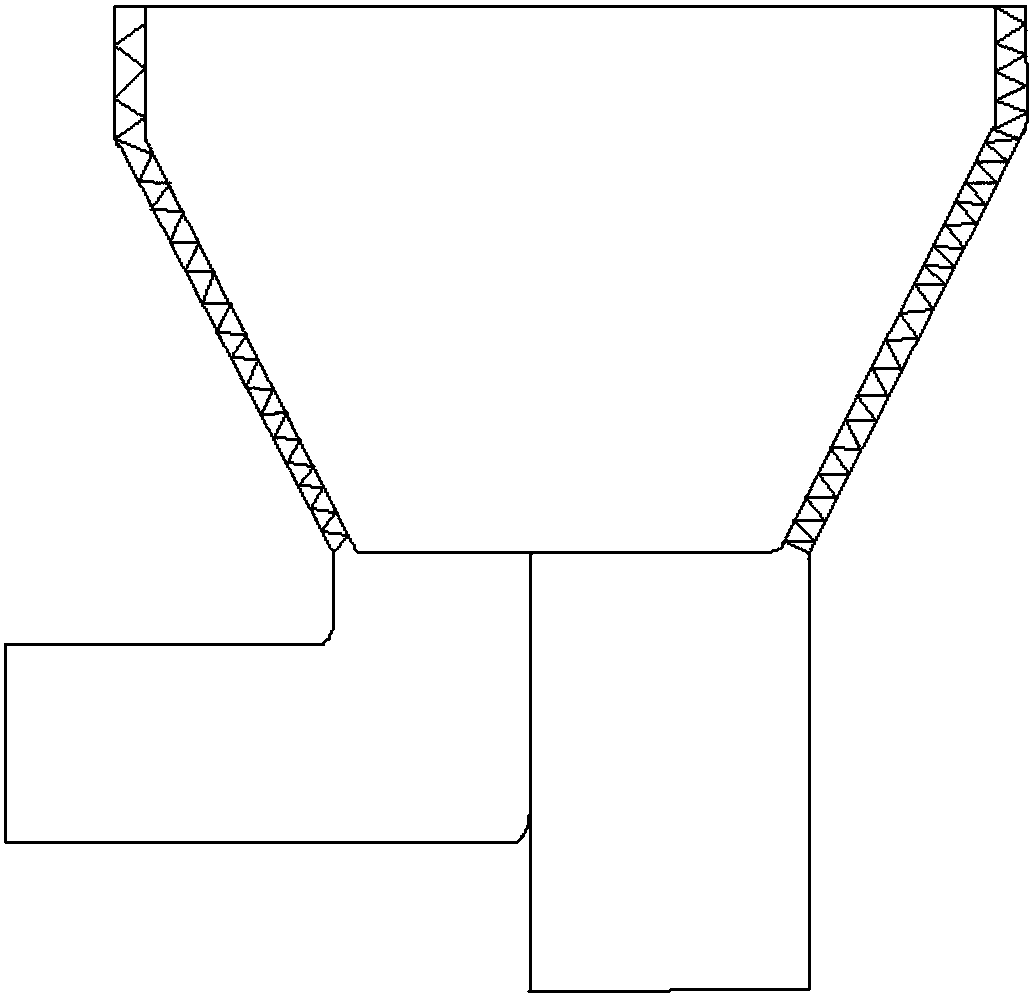

[0032] On the basis of embodiment two, a pusher for pushing the coking material in the gray matter screening area 4-5 to the coking material output area 4-6 is provided between the gray matter screening area 4-5 and the coking material discharge area 4-6. Material organization;

[0033] When the pushing mechanism is not provided, the coking material in the gray matter screening area 4-5 will be pushed to the coking material discharge area 4-6 under the extrusion of the burned material in the first combustion chamber 2, but in this way, the biomass The efficiency of the particle burner is low, and it is faster to push the coking material in the ash screening area 4-5 to the coking material discharge area 4-6 by using the pushing mechanism;

[0034] Since the pushing mechanism includes a connecting rod, a rake connected to the connecting rod, and a drive mechanism for driving the connecting rod, the components in it are all conventional components, and this application does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com