Water treatment method and water treatment device

A water treatment device and water treatment technology, applied in water treatment parameter control, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult filtration, pore clogging and easy clogging, and achieve long-term stability filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

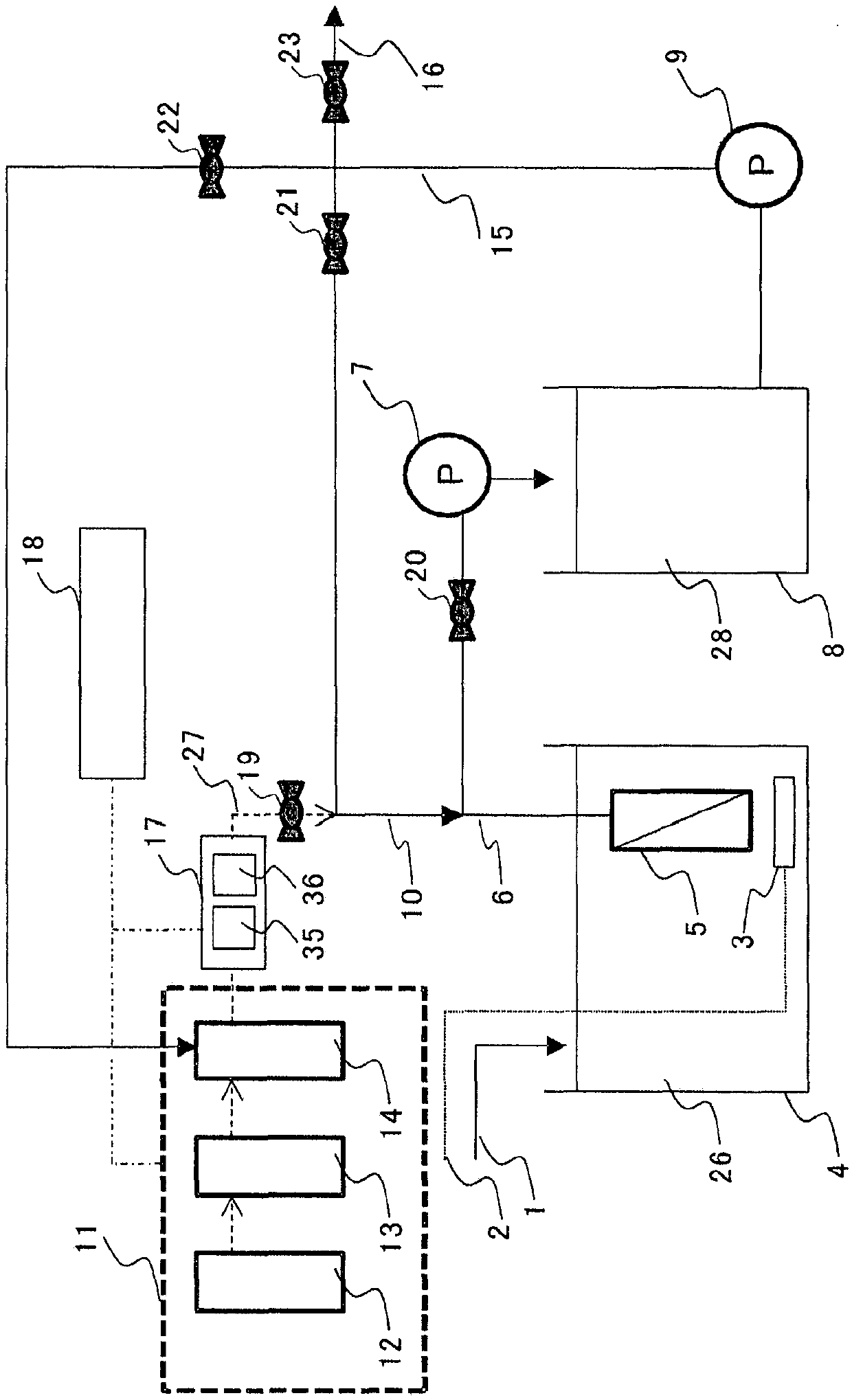

[0035] figure 1 It is a figure which shows the structure of the whole water treatment system at the time of applying the water treatment apparatus concerning Embodiment 1 of this invention to the immersion-type membrane separation activated sludge method. figure 1 The water treatment apparatus included in the water treatment device includes a water-to-be-treated introduction pipe 1 for introducing the water to be treated into the biological treatment tank 4 , and an air introduction pipe 2 for blowing air into the biological treatment tank 4 . The air introduction pipe 2 is connected to an air diffuser 3 .

[0036] It is installed so that the activated sludge 26 is accumulated in the biological treatment tank 4, and the separation membrane 5 is immersed in the activated sludge 26 separately. The separation membrane 5 is connected to a permeate transfer pipe 6 . Furthermore, a valve 20 and a membrane filtration pump 7 are provided on the permeate transfer pipe 6 .

[0037] I...

Embodiment approach 2

[0123] In Embodiment 2, a description will be given of a water treatment device capable of eliminating unnecessary washing with ozone and achieving suppression of the amount of ozone used.

[0124] Figure 5 It is a figure which shows the structure of the whole water treatment system at the time of applying the water treatment apparatus concerning Embodiment 2 of this invention to the immersion-type membrane separation activated sludge method. In this Embodiment 2 Figure 5 As far as the composition is concerned, it is the same as that in the previous Embodiment 1 figure 1 Compared with the configuration of the permeate water transfer pipe 6, the membrane property detector 24 and the inter-membrane pressure difference detector 25 are also different. Therefore, the following description will mainly focus on these differences.

[0125] In the present invention, as described in detail in Embodiment 1 above, ozone is brought into contact with the separation membrane 5 to modify...

Embodiment 2

[0174] The first time Q per unit membrane area becomes 600mgO 3 / m 2 To set the ozone water concentration C, the ozone water flow rate F, and the ozone injection time Ti to clean the separation membrane 5. Then, the ozone injection amount Q is kept constant, only the ozone injection time Ti is changed, and the cycle of filtration and cleaning is repeated.

[0175] After this cycle was repeated five times, the membrane was taken out from the tank, and the surface of the separation membrane 5 was washed with tap water. Next, the separation membrane 5 was moved into a water tank filled with ultrapure water, and the pressure difference of the clean water filtration at a water temperature of 25° C. was measured. By performing the verification according to this Example 2, the results in Table 2 below were obtained.

[0176] [Table 2]

[0177]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com