Self-cleaning filtering device

A filter device and self-cleaning technology, applied in the direction of filter separation, filter circuit, fixed filter element filter, etc., can solve the problems of automatic control, etc., to increase the self-cleaning effect, accelerate the accumulation of water, and have a long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

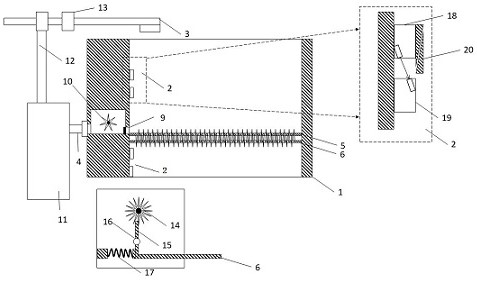

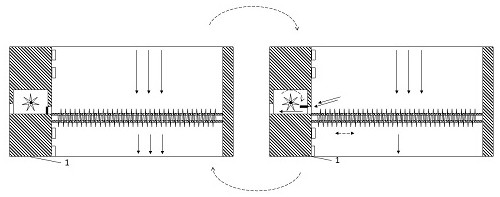

[0028] See attached Figure 1-4 , a self-cleaning filter device, including a filter tank 1, a filter screen, a turbidity detector 2, an inlet pipe 3 and a return pipe 4.

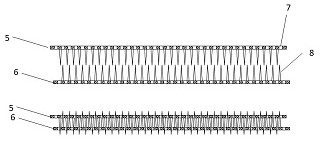

[0029] A filter screen is installed inside the filter pool 1, and the filter screen includes a fixed upper filter screen 5 and a movable lower filter screen 6, and the upper filter screen 5 and the lower filter screen 6 are all provided with an array of filter holes 7 and flexible spikes 8 , and the flexible spikes 8 of the upper filter 5 face the lower filter 6, the flexible spikes 8 of the lower filter 6 face the upper filter 5, and each filter hole 7 of the upper filter 5 corresponds to one of the lower filter 6 Flexible spikes 8, each filter hole 7 of the lower filter screen 6 corresponds to a flexible spike 8 of the upper filter screen 5, and the flexible spikes 8 are inserted into the filter holes 7;

[0030] The filter tank 1 is also provided with a bypass port 9, and a drive impeller 10 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com