Rope deterioration detection device and elevator apparatus having rope deterioration detection device

A technology of deterioration detection and rope, which is applied in the direction of measuring devices, transportation and packaging, and testing the strength of materials by applying a stable bending force, which can solve the problems of large measurement deviation, increased error, and difficult inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

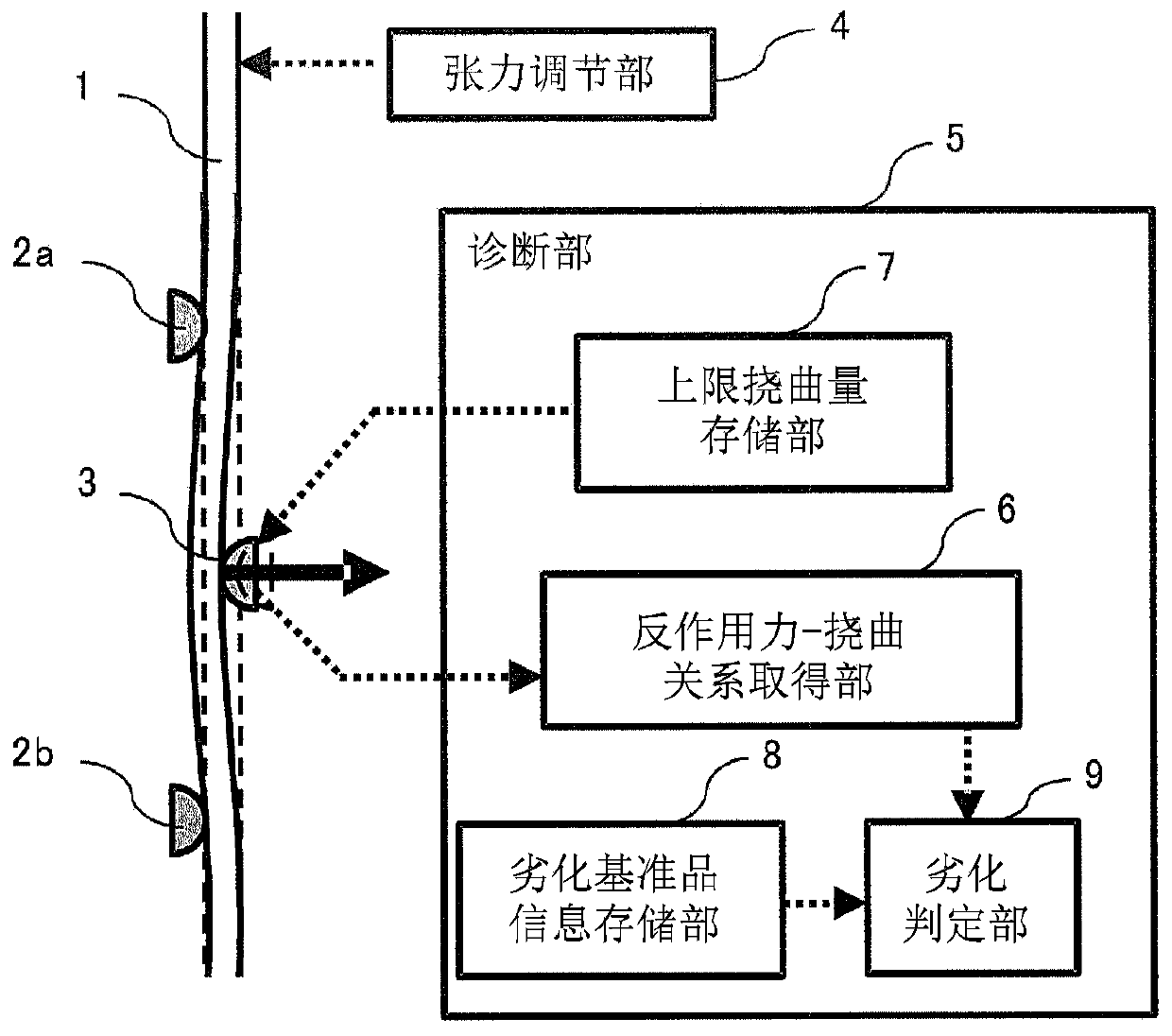

[0037] figure 1 It is a block diagram of the wire rope deterioration detection apparatus in Embodiment 1 of this invention. The cord 1 is provided with a support portion 2 a and a support portion 2 b for supporting the cord at both ends of a range to be diagnosed.

[0038] On the other hand, a bend imparting portion 3 is provided at an intermediate point between the support portion 2a and the support portion 2b, and the bend imparting portion 3 imparts a bend to the rope 1 supported by the support portion 2a and the support portion 2b. In addition, the tension adjustment unit 4 is provided at an arbitrary position outside the range of the diagnostic object. exist figure 1 In the example, the case where the tension adjustment part 4 is provided above the support part 2a is shown.

[0039] In addition, a diagnostic unit 5 is provided that receives the reaction force and the amount of deflection generated in the bending imparting unit 3 as inputs. The diagnostic unit 5 is con...

Embodiment approach 2

[0077] In Embodiment 1 above, the case where the height information of the normalized hysteresis loop is used as the deterioration diagnosis index has been described. On the other hand, in the second embodiment, a case will be described in which the area of the normalized hysteresis loop is used as the deterioration diagnosis index instead of the height information of the normalized hysteresis loop.

[0078] Figure 11 It is a graph showing the difference in the area of the normalized hysteresis loop in Embodiment 2 of the present invention. exist Figure 11 In , the hysteresis loop of the reaction force-deflection relationship of the intact rope is shown by a dotted line, and the hysteresis loop of the reaction force-deflection relationship of the deteriorated rope is shown by a solid line.

[0079] Such as Figure 11 As shown, in the deterioration diagnosis of the second embodiment, the area of the normalized hysteresis loop of the deterioration reference product is...

Embodiment approach 3

[0082] In the foregoing Embodiments 1 and 2, the case where the height or area of the normalized hysteresis loop is used as the deterioration diagnosis index has been described. On the other hand, in this third embodiment, a certain amount of deflection X within the range of the bending portion when a load is used for the determination will be described. 0 to replace the case of the hysteresis loop.

[0083] as deflection X 0 , for example, the intersection of straight lines before and after the bent portion can be used. Figure 12 It is a graph showing the relationship between the inflection point and the upper limit deflection amount X in the reaction force-deflection relationship in Embodiment 3 of the present invention. exist Figure 12 In , the reaction force-deflection relationship of the intact rope is shown by a dotted line, and the reaction force-deflection relationship of the deteriorated rope is shown by a solid line.

[0084] Such as Figure 12 As shown, sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com