Gunpowder tea production process

A production process and bead tea technology, applied in the field of bead tea production technology, can solve problems such as the influence of tea taste and quality, low tightness of bead tea, affecting the taste of tea leaves, etc., to achieve good toughness, improve quality, quality and stability. Taste-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

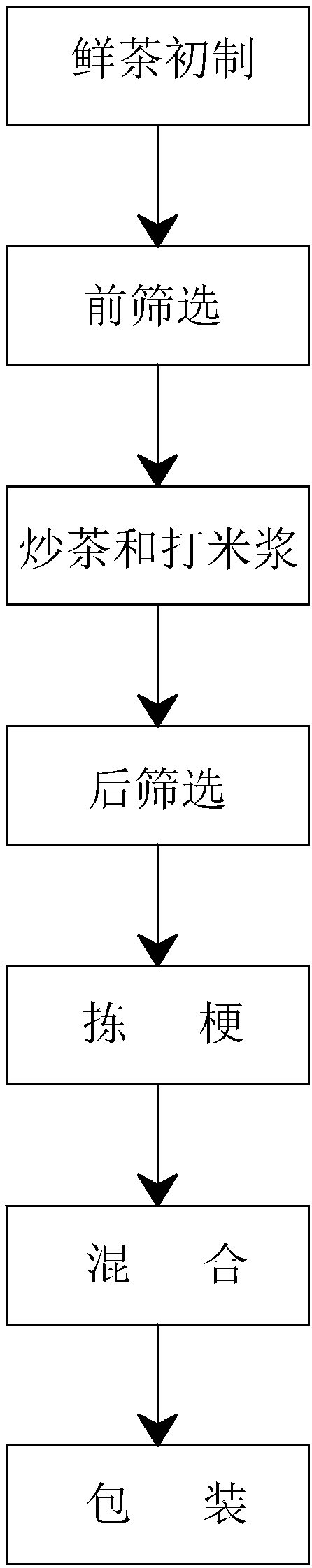

[0044] Such as figure 1 Shown, a kind of pearl tea production technique comprises the following steps:

[0045] (1) Primary preparation of fresh tea: process fresh leaves to obtain dried primary tea leaves, the moisture content of which is 8-13%;

[0046] (2) Pre-screening: Screen the primary tea leaves and classify the tea leaves according to their quality;

[0047] (3) Roasted tea and rice milk: tea leaves that have been screened before frying respectively. Roasted tea includes color processing and water processing. During color processing, the temperature of tea leaves is controlled at 45°C for 50 minutes. During water processing, tea leaves are controlled. The temperature is 80°C and the time is 50 minutes. Further reduce the moisture content of the tea leaves. During the frying process, the rice milk is evenly sprayed on the tea leaves, so that the surface of the tea leaves is covered with a uniform layer of rice milk. The moisture content of the tea leaves after frying...

Embodiment 2

[0057] A kind of pearl tea production process, comprises the following steps:

[0058] (1) Primary preparation of fresh tea: process fresh leaves to obtain dried primary tea leaves, the moisture content of which is 8-13%;

[0059] (2) Pre-screening: Screen the primary tea leaves and classify the tea leaves according to their quality;

[0060] (3) Roasted tea and rice milk: tea leaves that have been screened before roasting respectively. Roasted tea includes color processing and water processing. During color processing, the tea temperature is controlled at 55°C for 40 minutes. During water processing, the tea leaves are controlled. The temperature was 70°C and the time was 70 minutes. Further reduce the moisture content of the tea leaves. During the frying process, the rice milk is evenly sprayed on the tea leaves, so that the surface of the tea leaves is covered with a uniform layer of rice milk. The moisture content of the tea leaves after frying is 6-7%, and the tea leaves...

Embodiment 3

[0070] A kind of pearl tea production process, comprises the following steps:

[0071] (1) Primary preparation of fresh tea: process fresh leaves to obtain dried primary tea leaves, the moisture content of which is 8-13%;

[0072] (2) Pre-screening: Screen the primary tea leaves and classify the tea leaves according to their quality;

[0073] (3) Roasted tea and rice milk: tea leaves that have been screened before roasting respectively. Roasted tea includes color processing and water processing. During color processing, the tea temperature is controlled at 50°C for 45 minutes. During water processing, the tea leaves are controlled. The temperature was 75°C and the time was 60 minutes. Further reduce the moisture content of the tea leaves. During the frying process, the rice milk is evenly sprayed on the tea leaves, so that the surface of the tea leaves is covered with a uniform layer of rice milk. The moisture content of the tea leaves after frying is 6-7%, and the tea leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com