Microbial fermented feed and preparation method thereof

A technology of microbial fermentation and biological fermentation inoculum, which is applied in animal feed, animal feed, application, etc., can solve the problems of low nutrient conversion rate, unstable feed quality, and difficulty in controlling the degree of fermentation, so as to improve the utilization rate of feed. , the effect of promoting appetite and improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

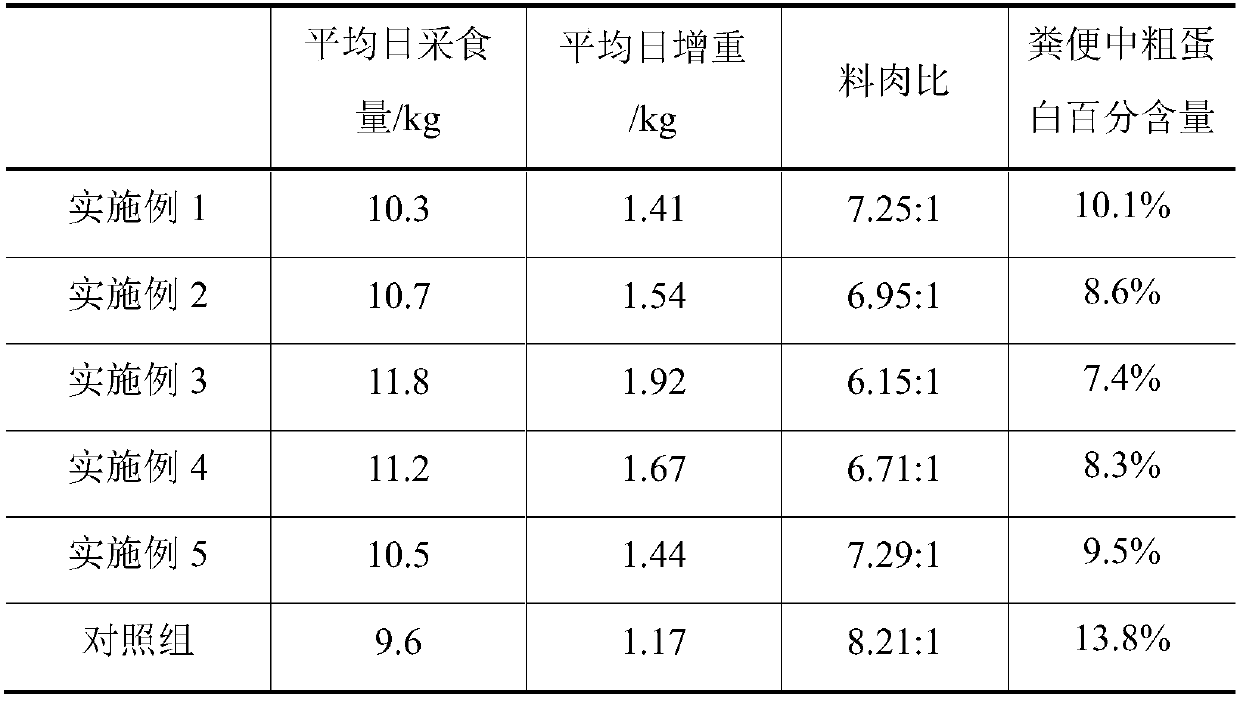

Examples

preparation example Construction

[0023] The invention provides a microbial fermented feed and a preparation method thereof, comprising:

[0024] Step 1. Cut the main ingredients into 3-4cm long pieces for later use. The main ingredients include the following components in parts by weight: 8-10 parts of corn stalks, 8-10 parts of clover, and 7-9 parts of alfalfa , 7-9 parts of pine pine vanilla, 7-9 parts of bean vine and 5-7 parts of sudan grass; the auxiliary materials are crushed to more than 30 mesh for subsequent use, and the auxiliary materials include the following components by weight: corn flour 5-7 5-7 parts of millet, 5-7 parts of shell powder, 2-4 parts of bean curd residue and 2-4 parts of brewer's grains;

[0025] Step 2. Send the main material and auxiliary materials into the mixer in a ratio of 1:1 and stir evenly, and add the aqueous solution of the enzyme preparation to infiltrate during the stirring process; the enzyme preparation includes the following components by weight: cellulase 3-5 p...

Embodiment 1

[0042] Cut the main ingredients into 3-4cm long pieces for later use. The main ingredients include the following components in parts by weight: 8 parts of corn stalks, 8 parts of clover, 7 parts of alfalfa, 7 parts of cypress herb, beans 7 parts of vine and 5 parts of Sudan grass;

[0043] The auxiliary materials are crushed to more than 30 mesh for later use, and the auxiliary materials include the following components in parts by weight: 5 parts of corn flour, 5 parts of millet, 5 parts of shell powder, 2 parts of bean curd residue and 2 parts of brewer's grains;

[0044] Put the main material cut to 3-4cm long and the auxiliary material powder crushed to more than 30 mesh in a sterilizing equipment at 121°C for 20 minutes for disinfection; and sterilize the mixer;

[0045] The main material and the auxiliary material are sent into the mixer in a ratio of 1:1 and stirred evenly, and the aqueous solution of the enzyme preparation is added to infiltrate during the stirring pro...

Embodiment 2

[0049] Cut the main ingredients into 3-4cm long pieces for later use. The main ingredients include the following components in parts by weight: 9 parts of corn stalks, 9 parts of clover, 8 parts of alfalfa, 8 parts of cypress herb, beans 8 parts of vine and 6 parts of Sudan grass;

[0050] The auxiliary materials are crushed to more than 30 mesh for later use, and the auxiliary materials include the following components in parts by weight: 6 parts of corn flour, 6 parts of millet, 6 parts of shell powder, 3 parts of bean curd residue and 3 parts of brewer's grains;

[0051] Put the main material cut to 3-4cm long and the auxiliary material powder crushed to more than 30 mesh in a sterilizing equipment at 121°C for 20 minutes for disinfection; and sterilize the mixer;

[0052] The main material and the auxiliary material are sent into the mixer in a ratio of 1.25:1 and stirred evenly, and the aqueous solution of the enzyme preparation is added to infiltrate during the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com