Water chestnut drying and cleaning equipment

A technology for cleaning equipment and water chestnuts, applied in food processing, application, food science and other directions, can solve the problem that the fruit cannot be stored for a long time, achieve good soil removal effect and prevent environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

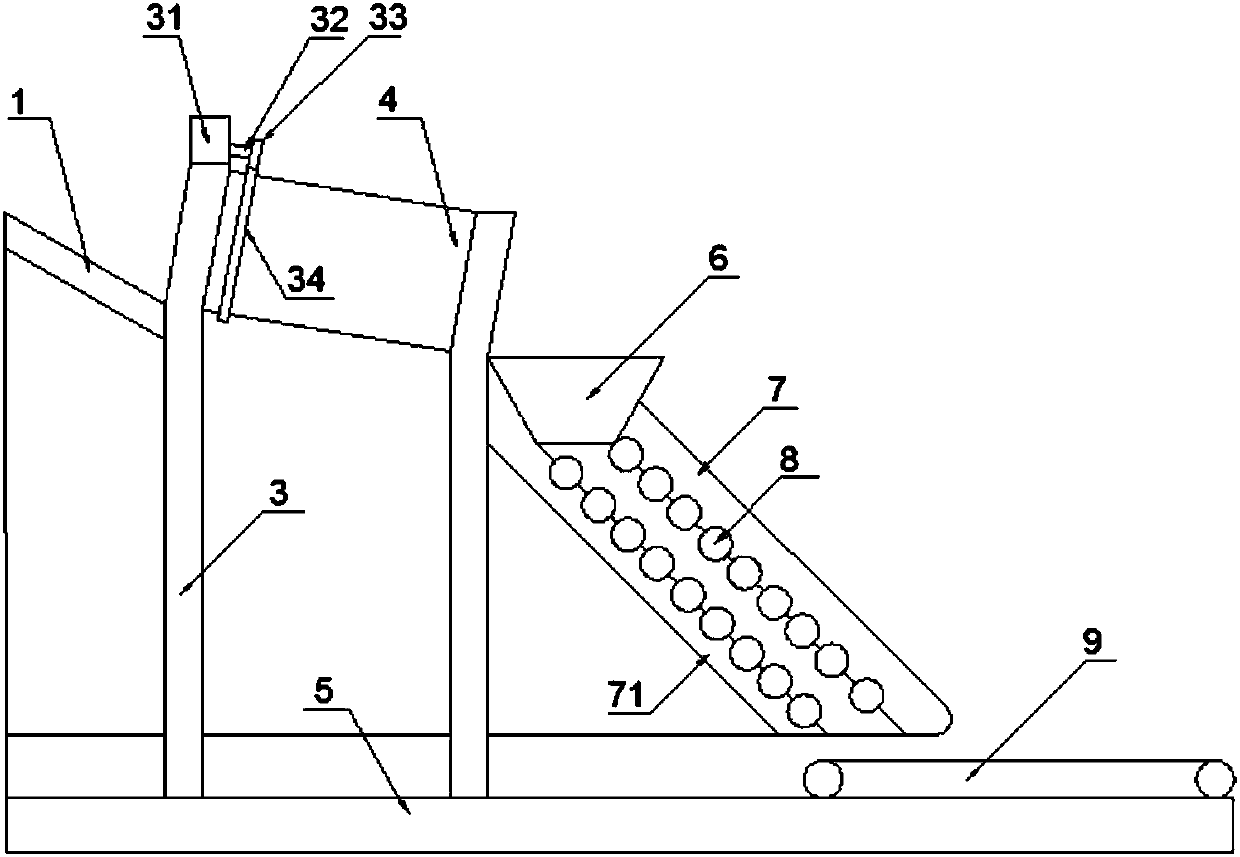

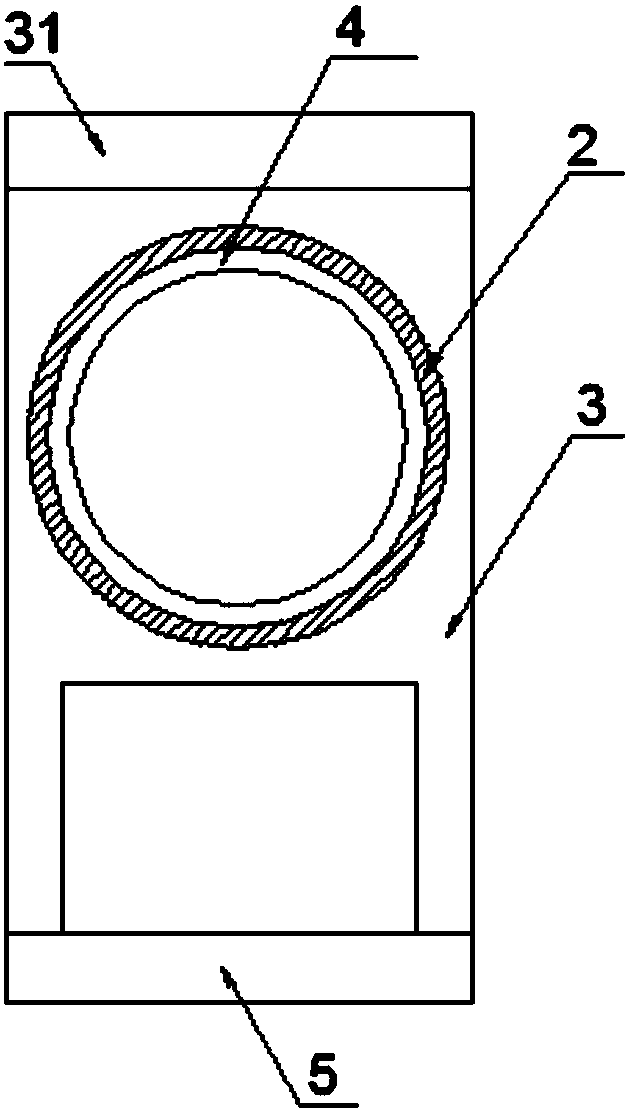

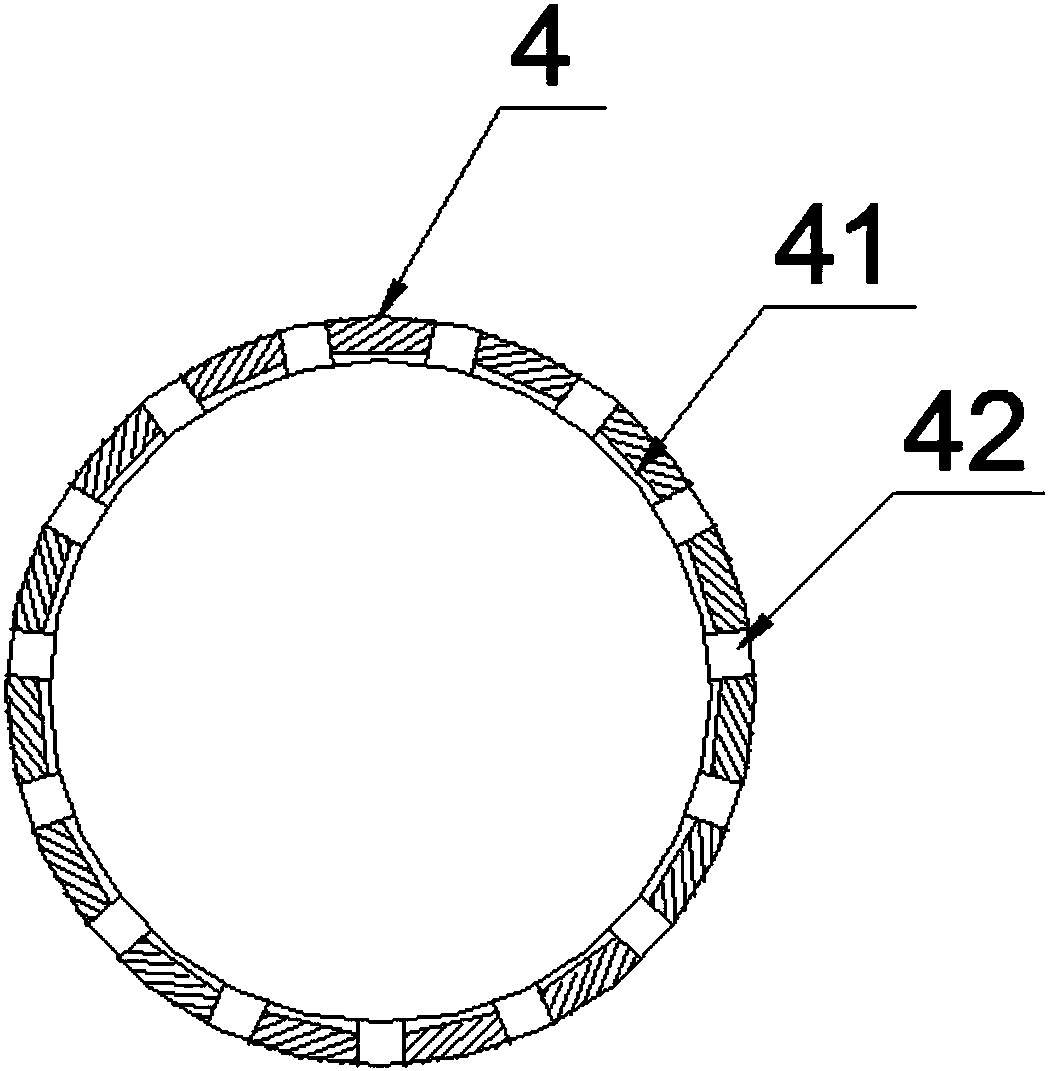

[0020] Such as Figure 1-3 as shown, figure 1 It is the structural representation of a kind of horseshoe fruit drying cleaning equipment that the present invention proposes, figure 2 It is a partial structure schematic diagram in the water chestnut drying and cleaning equipment proposed by the present invention, image 3 It is a structural schematic diagram of the soil removal drum in the water chestnut fruit drying and cleaning equipment proposed by the present invention.

[0021] refer to Figure 1-3 , a kind of horseshoe fruit drying and cleaning equipment that the present invention proposes, comprises base 1 and along the feeding plate 1 that is arranged on the base 1 successively along working direction, removes soil cylinder 4, conveying device 6 and discharge plate 9; 1 is connected to the feeding port of soil removal drum 4;

[0022] The two ends of the soil-removing cylinder 4 are fixed on the support 3, the load-bearing bearing 2 is arranged between the soil-rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com