Method for coating sevelamer carbonate tablets

A sevelamer carbonate and coating technology, which is applied in the coating field of sevelamer carbonate tablets, can solve the problem of tablet core powder dropping, achieve the effects of preventing moisture absorption, suppressing powder dropping, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

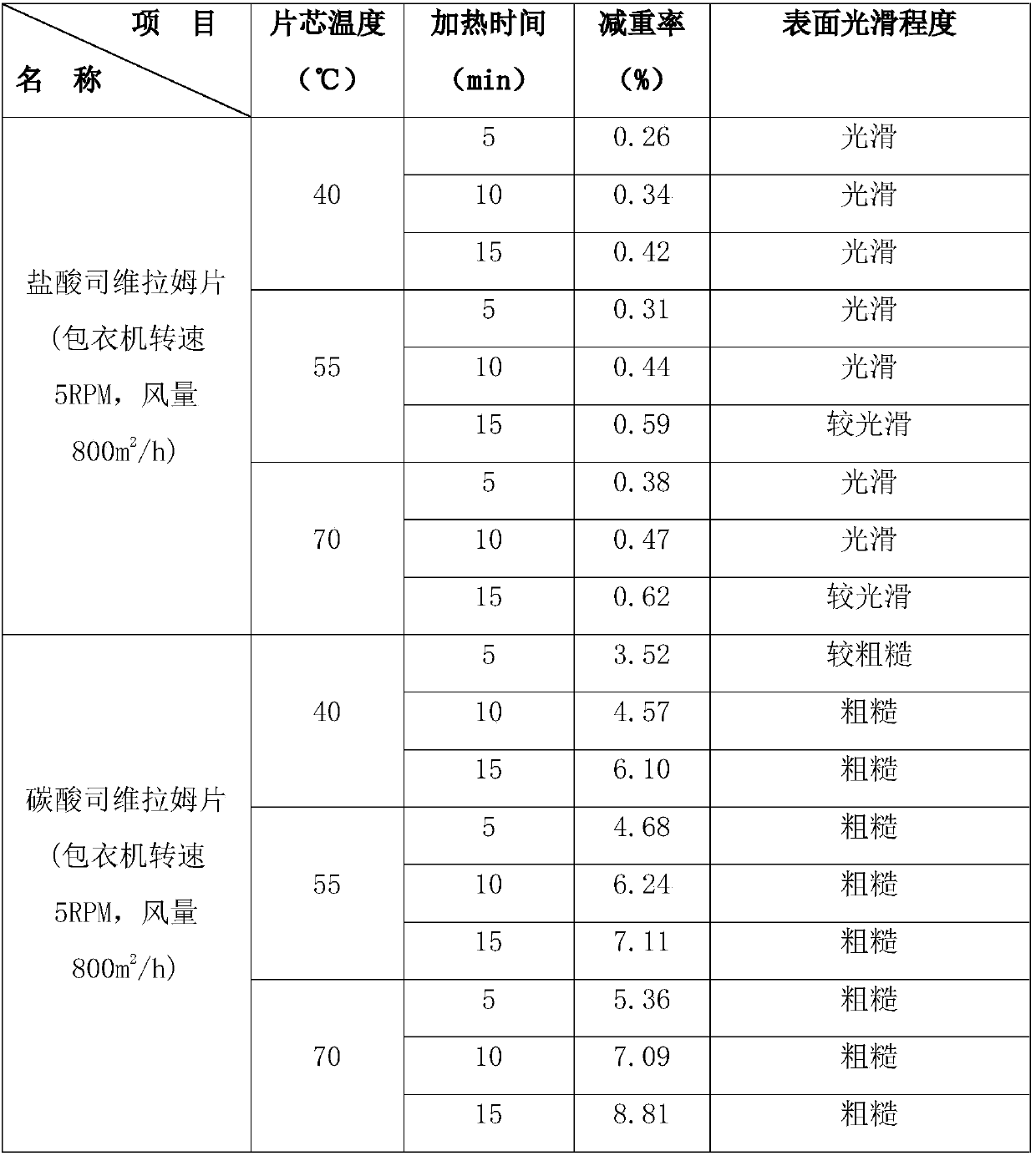

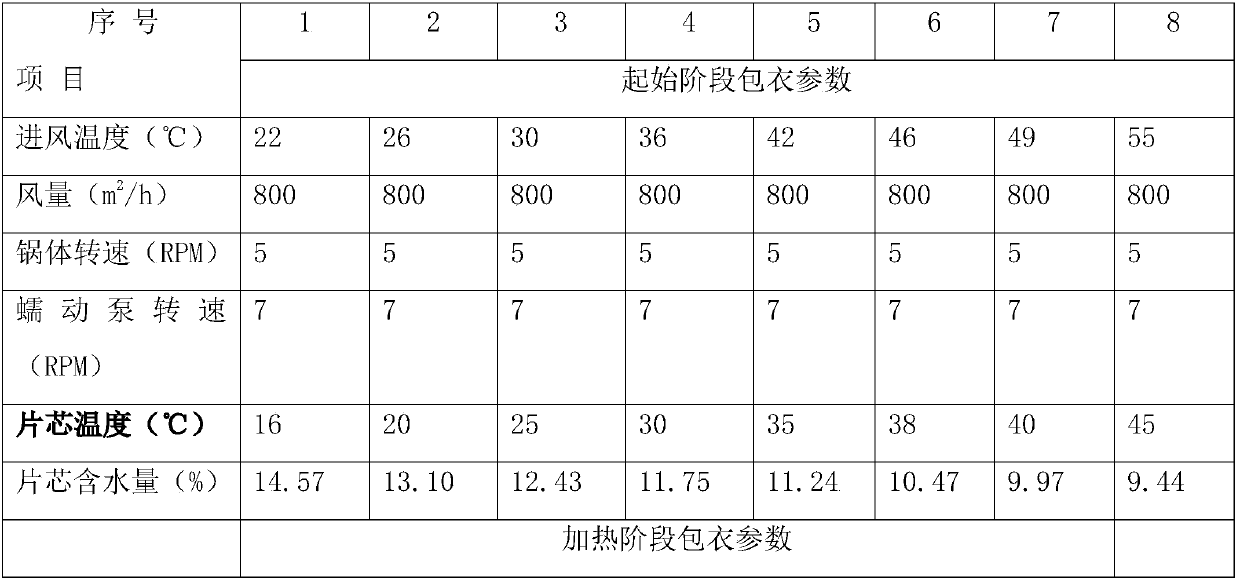

[0028] Put 800g of sevelamer carbonate (calculated as the dry product) and 100g of microcrystalline cellulose in a wet mixing granulator and mix well, add about 50g of purified water (to make the total water content of the material 11%), and granulate , Add 5 g of magnesium stearate and mix until uniform, and prepare sevelamer carbonate tablet cores with a tablet press. Dissolve or suspend 50 g of Opadry Clear, a coating material, with 450 g of purified water, and set aside. Place the sevelamer carbonate tablet cores in the high-efficiency coating machine, start the main machine of the coating machine, make the cores turn continuously in the pan, control the core temperature, turn on the spray gun, and spray the prepared coating liquid on On the surface of the tablet core, after the tablet core has a layer of coating material, heat the tablet core and control the temperature, and continue to spray the coating liquid until the surface of the sevelamer carbonate tablet is smooth,...

Embodiment 2

[0034] Put 800g of sevelamer carbonate (calculated as the dry product) and 100g of microcrystalline cellulose in a wet mixing granulator and mix well, add about 50g of purified water (to make the total water content of the material 11%), and granulate , Add 5 g of magnesium stearate and mix until uniform, and prepare sevelamer carbonate tablet cores with a tablet press. Dissolve or suspend 50 g of Opadry Clear, a coating material, with 450 g of purified water, and set aside. Place the sevelamer carbonate tablet cores in the high-efficiency coating machine, start the main machine of the coating machine, make the cores turn continuously in the pan, control the core temperature, turn on the spray gun, and spray the prepared coating liquid on On the surface of the tablet core, after the tablet core has a layer of coating material, heat the tablet core and control the temperature, and continue to spray the coating liquid until the surface of the sevelamer carbonate tablet is smooth,...

Embodiment 3

[0040] Put 800g of sevelamer carbonate (calculated as the dry product) and 100g of microcrystalline cellulose in a wet mixing granulator and mix well, add about 50g of purified water (to make the total water content of the material 11%), and granulate , Add 5 g of magnesium stearate and mix until uniform, and prepare sevelamer carbonate tablet cores with a tablet press. Dissolve or suspend 50 g of Opadry Clear, a coating material, with 450 g of purified water, and set aside. Place the sevelamer carbonate tablet cores in the high-efficiency coating machine, start the main machine of the coating machine, make the cores turn continuously in the pan, control the core temperature, turn on the spray gun, and spray the prepared coating liquid on On the surface of the tablet core, after the tablet core has a layer of coating material, heat the tablet core and control the temperature, and continue to spray the coating liquid until the surface of the sevelamer carbonate tablet is smooth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com