Copper foil for printed circuit board and preparation method thereof

A technology for printed circuit boards and copper foils, which is applied in the field of improved copper foils for printed circuit boards and its preparation, can solve the problems of complex curing process and long process flow, and achieves the effect of overcoming technical prejudice and solving powder removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

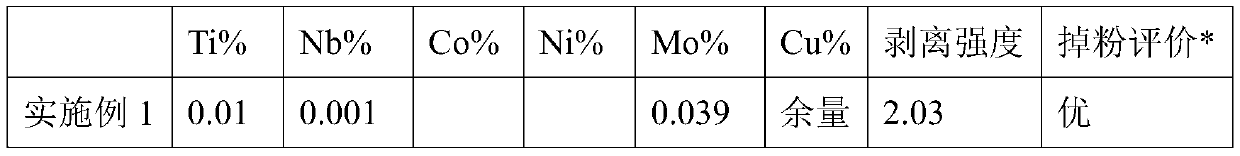

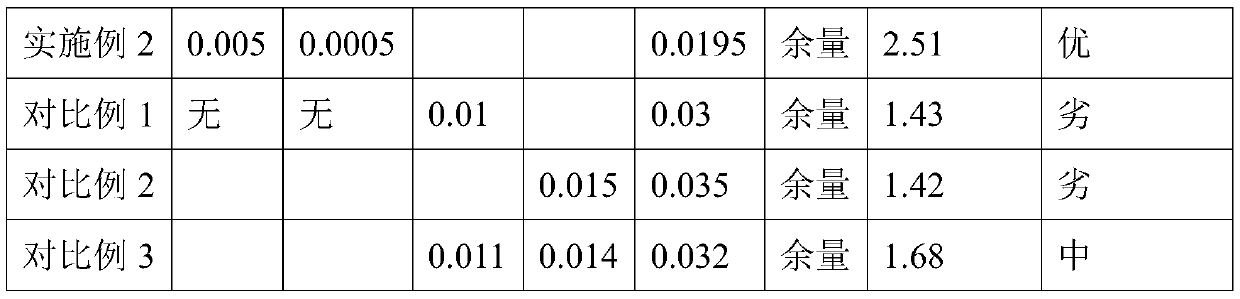

Embodiment 1

[0034] Plating an untreated copper foil with a thickness of 15 microns and a roughness Rz of the surface to be treated = 3.8 μm, the plating solution is a conventional copper sulfate electrolyte, the concentration of copper sulfate is 70g / L, and the concentration of sulfuric acid is 110g / L , titanium tetrachloride 1.0g / L, niobium oxalate 0.2g / L, ammonium molybdate 3.5g / L, sodium cyanide 15g / L, potassium sodium tartrate 8g / L, the current density is 25A / dm 2 , the electroplating time is 8 seconds, the temperature of the electroplating solution is 40° C., and the thickness is 0.5 μm.

Embodiment 2

[0036] Plating an untreated copper foil with a thickness of 15 microns and a roughness Rz of the surface to be treated = 3.8 μm, the plating solution is a conventional copper sulfate electrolyte, the concentration of copper sulfate is 80g / L, and the concentration of sulfuric acid is 150g / L , titanium tetrachloride 0.6g / L, niobium oxalate 0.12g / L, sodium molybdate 1.8g / L, sodium cyanide 25g / L, potassium sodium tartrate 12g / L, the current density is 35A / dm 2 , the electroplating time is 6 seconds, the temperature of the electroplating solution is 35° C., and the thickness is 1.0 μm.

[0037] The above-mentioned electrolytically roughened alloy copper foil layer undergoes conventional follow-up treatment (including plating copper plating, nickel plating, zinc plating or a combination of any of them on the alloy layer), so as to be laminated with a resin substrate to prepare a printed circuit board laminate version and perform performance tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com