Modified melamine hard foam material and preparation method thereof

A technology of melamine and foaming materials, applied in the field of polymer materials, can solve the problems of poor product quality stability, inability to meet the requirements of use strength, insufficient bonding strength of the matrix, etc. The effect of increased porosity and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

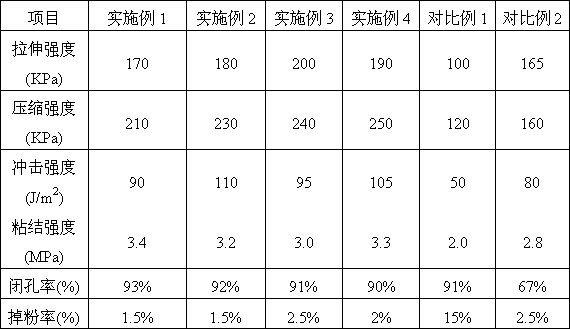

Examples

Embodiment 1

[0024] Add 300g of water, 330g of paraformaldehyde and 550g of melamine into the reaction kettle, raise the temperature to 85°C, adjust the pH of the system to 8.0 with triethanolamine, and stir for 45 minutes; dissolve 60g of benzoxazine and 80g of polyvinyl butyral Add 150g of isobutanol to the reaction kettle together, lower the temperature to 75°C, adjust the reaction pH to 7.0 with 1% hydrochloric acid, and stir for 1.5 hours to obtain a melamine prepolymer resin solution.

[0025] Take 500g of melamine prepolymer resin liquid, add 22g of acetic acid, 30g of n-pentane, 26g of sodium dodecylbenzenesulfonate, and 15g of tetrafluoroethyl methyl ether, stir well, foam in a microwave oven for 5min, and foam The power is 2000W, and then moved to an oven for aging at 60°C for 20 hours to obtain a modified melamine rigid foam material.

Embodiment 2

[0027] Add 400g of water, 370g of paraformaldehyde and 650g of melamine into the reaction kettle, raise the temperature to 90°C, adjust the pH of the system to 8.5 with triethanolamine, and stir for 60 minutes; dissolve 40g of benzoxazine and 60g of polyvinyl butyral Add 120g of isobutanol to the reaction kettle together, lower the temperature to 70°C, adjust the reaction pH to 6.5 with 1% hydrochloric acid, and stir for 1.2 hours to obtain a melamine prepolymer resin solution.

[0028] Take 500g of melamine prepolymer resin liquid, add 26g of formic acid, 20g of isohexane, 22g of sodium lauryl sulfate, 16g of tetrafluoroethyl tetrafluoropropyl ether, stir well, foam in a microwave oven for 3min, and the foaming power It is 1600W, and then moved to an oven for aging at 50°C for 24 hours to obtain a modified melamine rigid foam material.

Embodiment 3

[0030] Add 350g of water, 300g of paraformaldehyde and 610g of melamine into the reaction kettle, raise the temperature to 82°C, adjust the pH of the system to 9.0 with triethanolamine, and stir for 35 minutes. Dissolve 90g of benzoxazine and 40g of polyvinyl butyral in 110g of isobutanol and put them into the reaction kettle together, lower the temperature to 80°C, adjust the reaction pH to 7.5 with 1% hydrochloric acid, and stir for 1.8 hours to obtain Melamine prepolymer resin liquid.

[0031] Take 500g of melamine prepolymer resin liquid, add 22g of oxalic acid, 25g of dichloromethane, 24g of sodium fatty alcohol polyoxyethylene ether sulfate, and 18g of heptafluoroisopropylmethyl ether, stir evenly, and foam in a microwave oven for 4min. The foaming power was 1800W, and then moved to an oven for aging at 70° C. for 16 hours to obtain a modified melamine rigid foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com