Automatic assembling production line for automobile B pillar

An automatic assembly and production line technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of long production lines, low efficiency, high costs, etc., to save costs, reduce labor intensity, and have strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

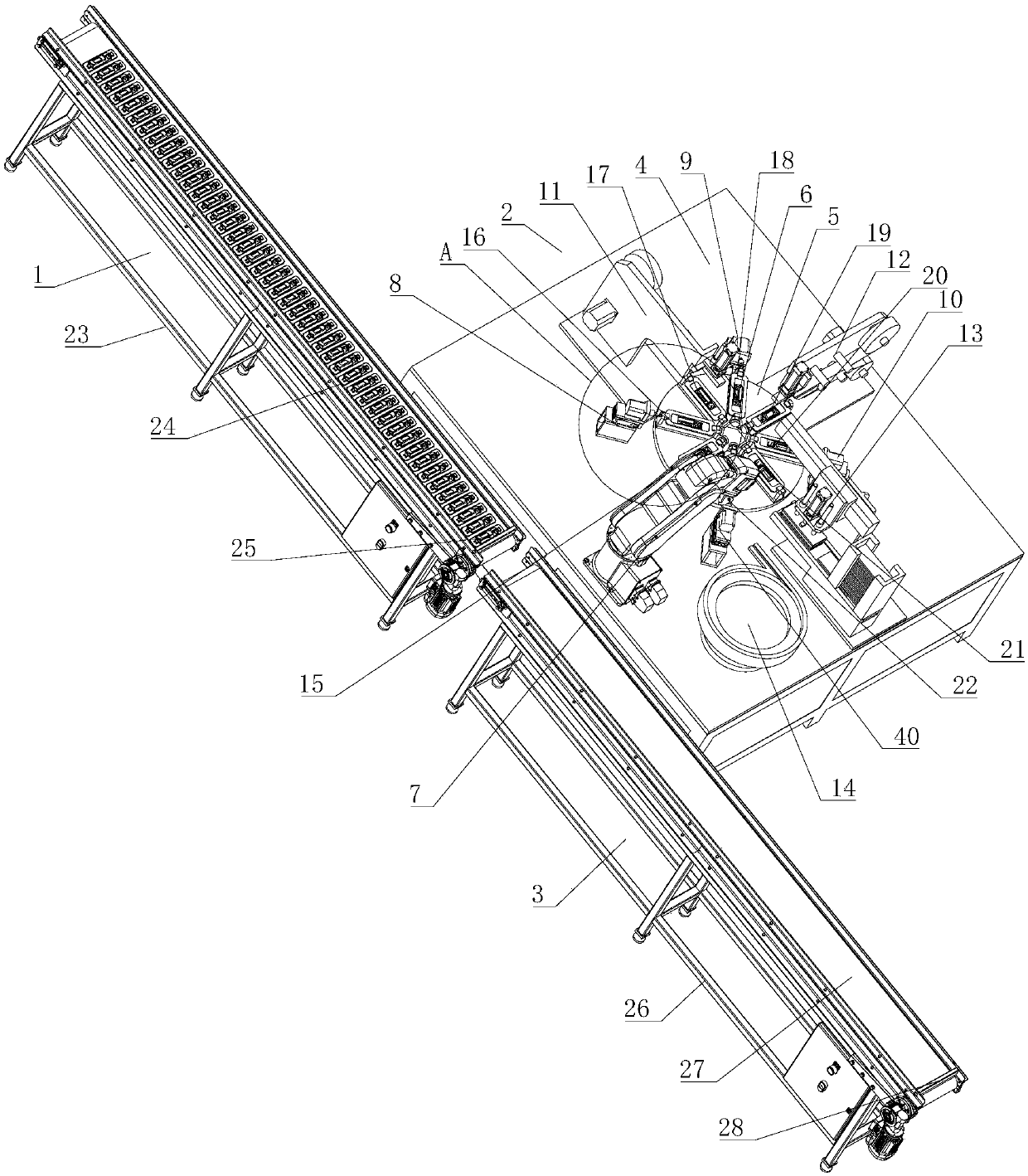

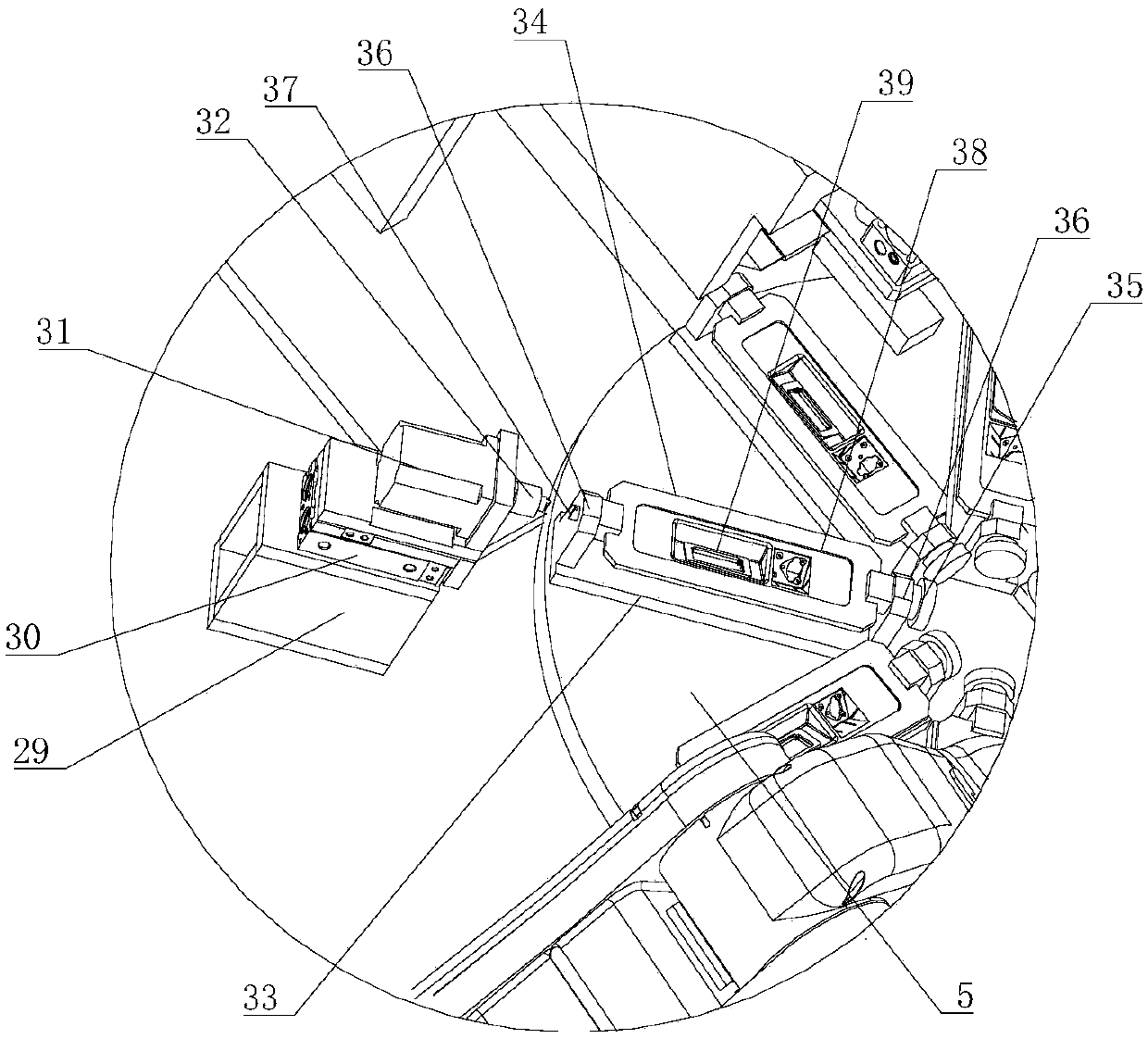

[0020] like figure 1 As shown, the automobile B-pillar automatic assembly production line includes a feeding conveyor 1, an automatic assembly machine 2, and an unloading conveyor 3; 6. Single-arm robot 7, the first jig rotating device 8, the second jig rotating device 9, the third jig rotating device 10, the fourth jig rotating device 40, the first automatic foam sticking device 11, the second jig rotating device Two automatic foam sticking device 12, automatic sticking sealing device 13, buckle automatic feeding vibrating plate 14; the conveying turntable 5 is arranged at the center of the frame platform 4, and the eight described automobile B-pillar fixtures 6 are Radiation is evenly distributed circumferentially on the conveying turntable 5 to form the first station 15, the second station 16, the third station 17, the fourth station 18, the fifth station 19, the sixth station 20, and the seventh station 21. The eighth station 22; the operating range of the single-arm robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com