Automatic polishing machine based on annular assembled plates

A polishing machine and a ring-shaped technology, which are applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of low efficiency, inability to ensure consistent surface polishing specifications of wood boards, and uneven polishing quality of wood boards and other problems, to achieve the effect of high processing efficiency, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

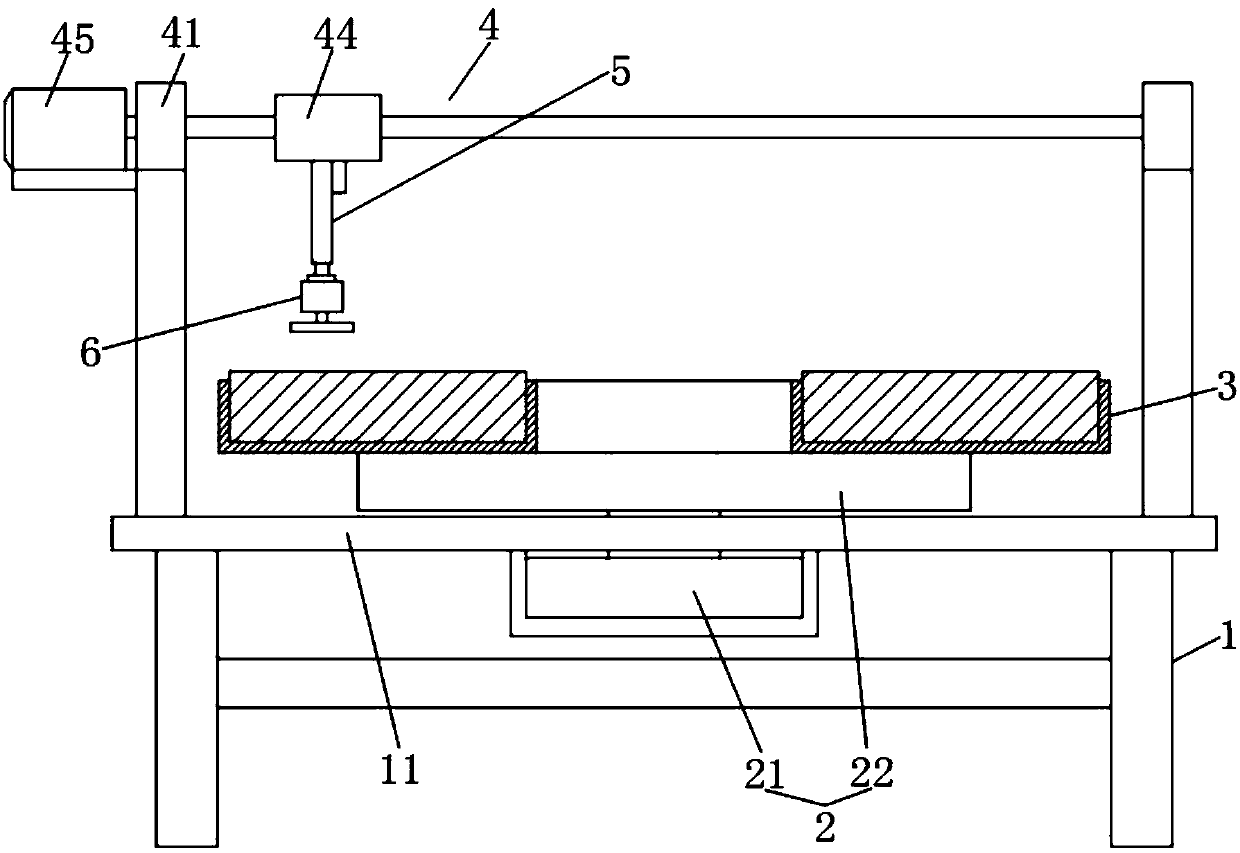

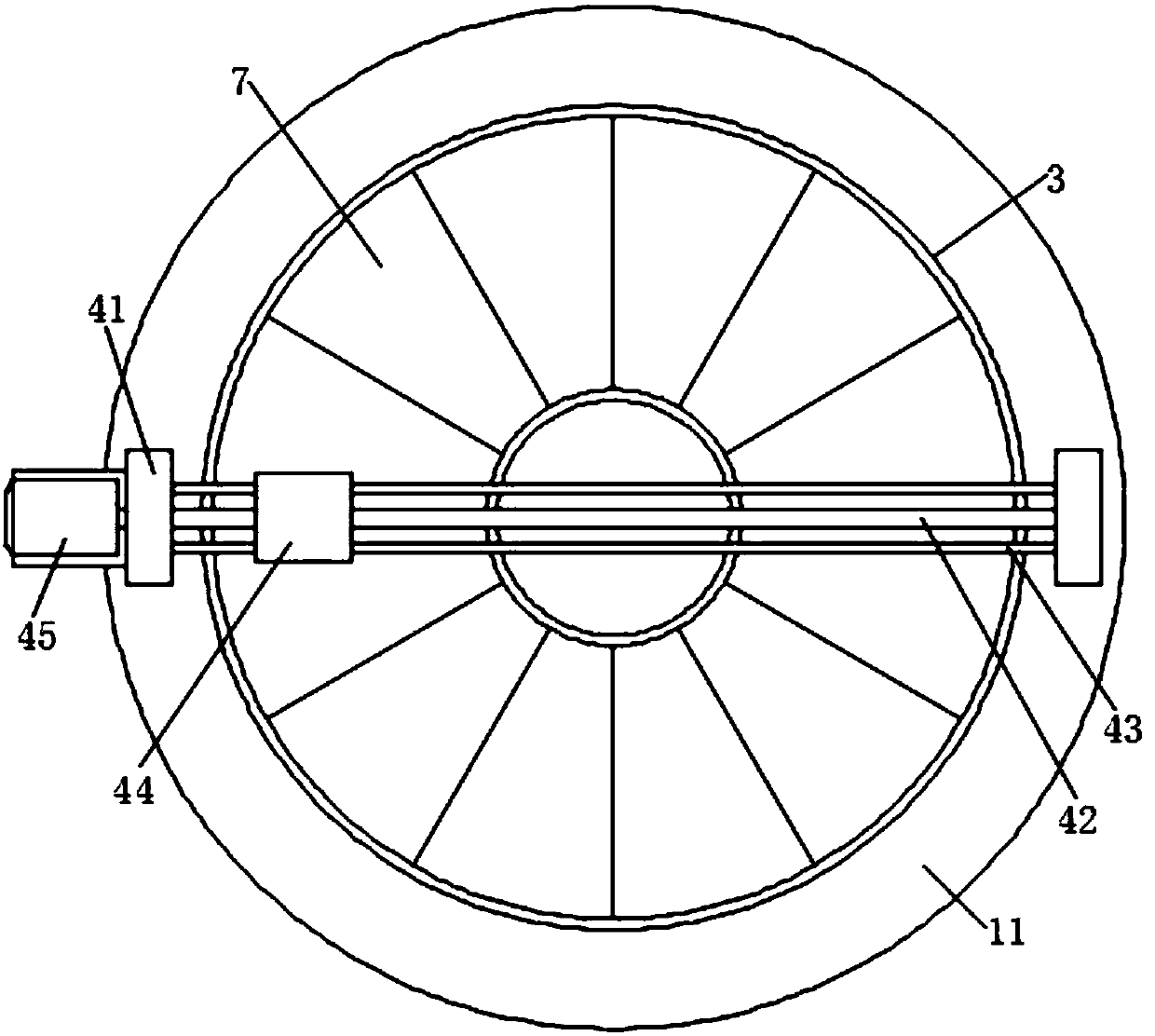

[0037] Example: such as figure 1 and 2 As shown, the automatic polishing machine based on the circular assembled board of the present embodiment includes a frame 1, a rotary drive device 2, a circular plank placement groove 3, a linear moving mechanism 4, a lifting mechanism 5 and a polishing machine 6;

[0038] The upper end of the above-mentioned frame 1 has a processing table 11 arranged horizontally;

[0039] The above-mentioned rotary driving device 2 is installed on the above-mentioned processing table 11;

[0040] The above-mentioned plank placing groove 3 is installed horizontally on the driving end of the above-mentioned rotary driving device 2, and the above-mentioned rotating driving device 2 can drive the above-mentioned plank placing groove 3 to rotate horizontally;

[0041] The above-mentioned linear moving mechanism 4 is erected horizontally above the above-mentioned plank placement groove 3;

[0042] The above-mentioned lifting mechanism 5 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com