Modified lead zirconate titanate powder and preparation method thereof as well as piezoelectric ceramic forming blank

A lead zirconate titanate and piezoelectric ceramic technology, applied in the field of piezoelectric ceramics, can solve the problems of cracks and pores, difficult to form piezoelectric ceramics, low density, etc., and achieves good surface finish, good resin compatibility, Excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a preparation method of modified lead zirconate titanate powder, comprising the following steps:

[0043] A) According to the molar ratio of Pb in the chemical formula shown in formula I: Nb: Ni: Zr: Ti=(1-y-z): y: z: a: (1-a) Weigh ZrO 2 、TiO 2 , Pb 3 o 4 , NiO and NbO are mixed to obtain a mixture;

[0044] B) performing ball milling, rotary evaporation and drying on the mixture in the step A) in sequence to obtain an intermediate;

[0045] C) sintering the intermediate to obtain lead zirconate titanate powder having the chemical formula shown in formula I;

[0046] Pb 1-y-z Nb y Ni z (Zr a Ti 1-a )O 3 Formula I;

[0047] Wherein, 0

[0048] In the present invention, the values of y, z and a are consistent with the value ranges above, and will not be repeated here.

[0049] In the present invention, the mixture is preferably placed in a polytetrafluoroethylene ball mill jar, and grinding balls and gr...

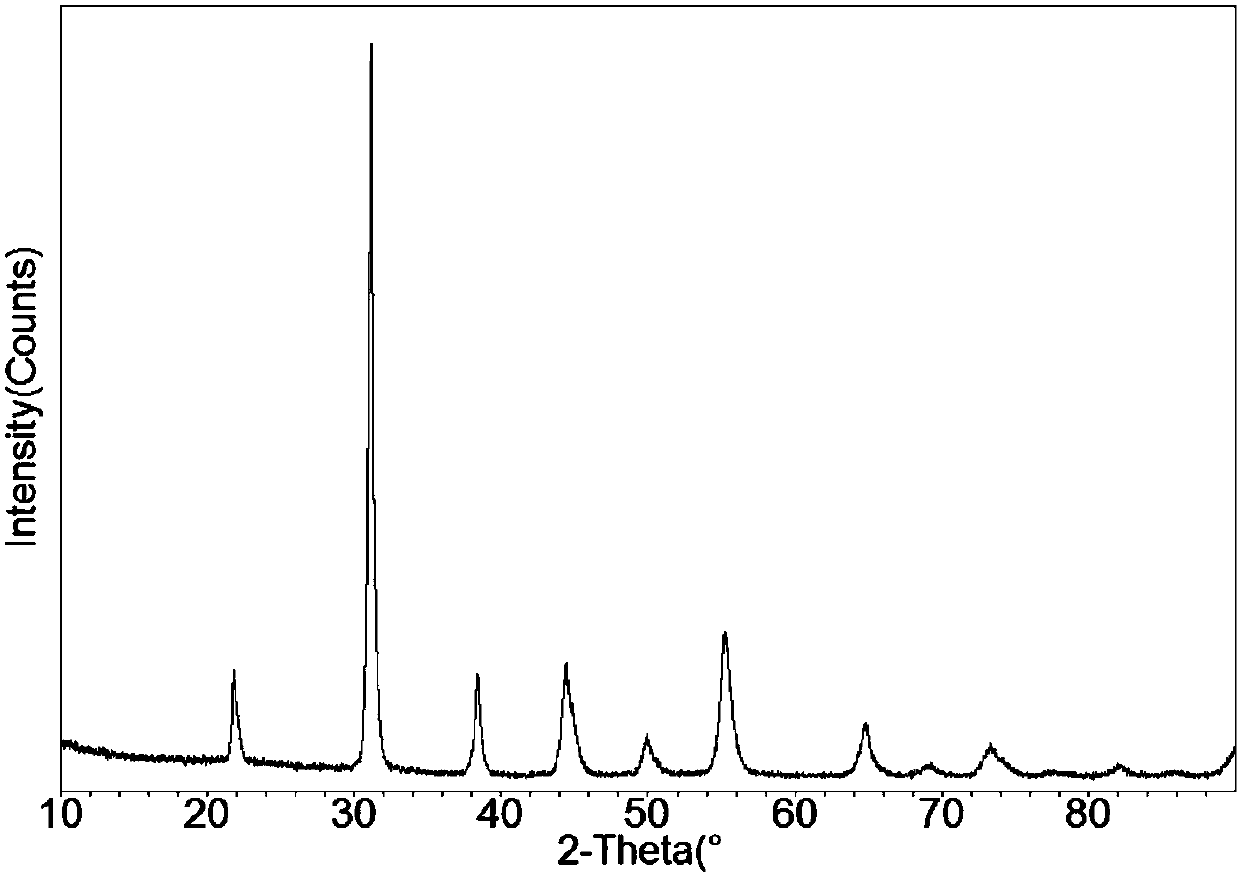

Embodiment 1

[0075] Synthesize Pb as follows 0.92 Nb 0.05 Ni 0.03 (Zr 0.52 Ti 0.48 )O 3 Powder.

[0076] (1) According to the molar ratio of each element of the modified lead zirconate titanate powder to be synthesized Zr:Ti:Pb:Nb:Ni:=0.52:0.48:0.92:0.05:0.03, weigh ZrO 2 、TiO 2 and Pb 3 o 4 The main component raw materials are mixed with NiO and NbO modification additives to obtain a mixture one.

[0077] (2) Place the mixture one described in feature (1) in a polytetrafluoroethylene ball mill jar, add zirconia grinding balls and absolute ethanol, the mass ratio is: mixture one: ball milling medium: water=100%: 300%: 15%, using 350r / min speed ball milling for 3 hours to obtain the mixture two.

[0078] (3) Use a rotary evaporator to evaporate absolute ethanol from mixture 2 described in feature (2), and then place evaporated mixture 3 in an oven at 60° C. for 8 hours to dry to obtain mixture 4.

[0079] (4) Put the mixture described in feature (3) in a closed alumina crucible, ...

Embodiment 2

[0081] Synthesize Pb as follows 0.92 Nb 0.05 Ni 0.03 (Zr 0.60 Ti 0.40 )O 3 Powder.

[0082](1) According to the molar ratio of each element of the modified lead zirconate titanate powder to be synthesized Zr:Ti:Pb:Nb:Ni:=0.60:0.40:0.92:0.05:0.03, weigh ZrO 2 、TiO 2 and Pb 3 o 4 The main component raw materials are mixed with NiO and NbO modification additives to obtain a mixture one.

[0083] (2) Place the mixture one described in feature (1) in a polytetrafluoroethylene ball mill jar, add zirconia grinding balls and absolute ethanol, the mass ratio is: mixture one: ball milling medium: water=100%: 300%: 15%, using 350r / min speed ball milling for 5 hours to obtain the mixture two.

[0084] (3) Use a rotary evaporator to evaporate absolute ethanol from the mixture 2 described in feature (2), and then place the evaporated mixture 3 in an oven at 80°C for 6 hours to dry to obtain the mixture 4.

[0085] (4) Put the mixture described in feature (3) in a closed alumina c...

PUM

| Property | Measurement | Unit |

|---|---|---|

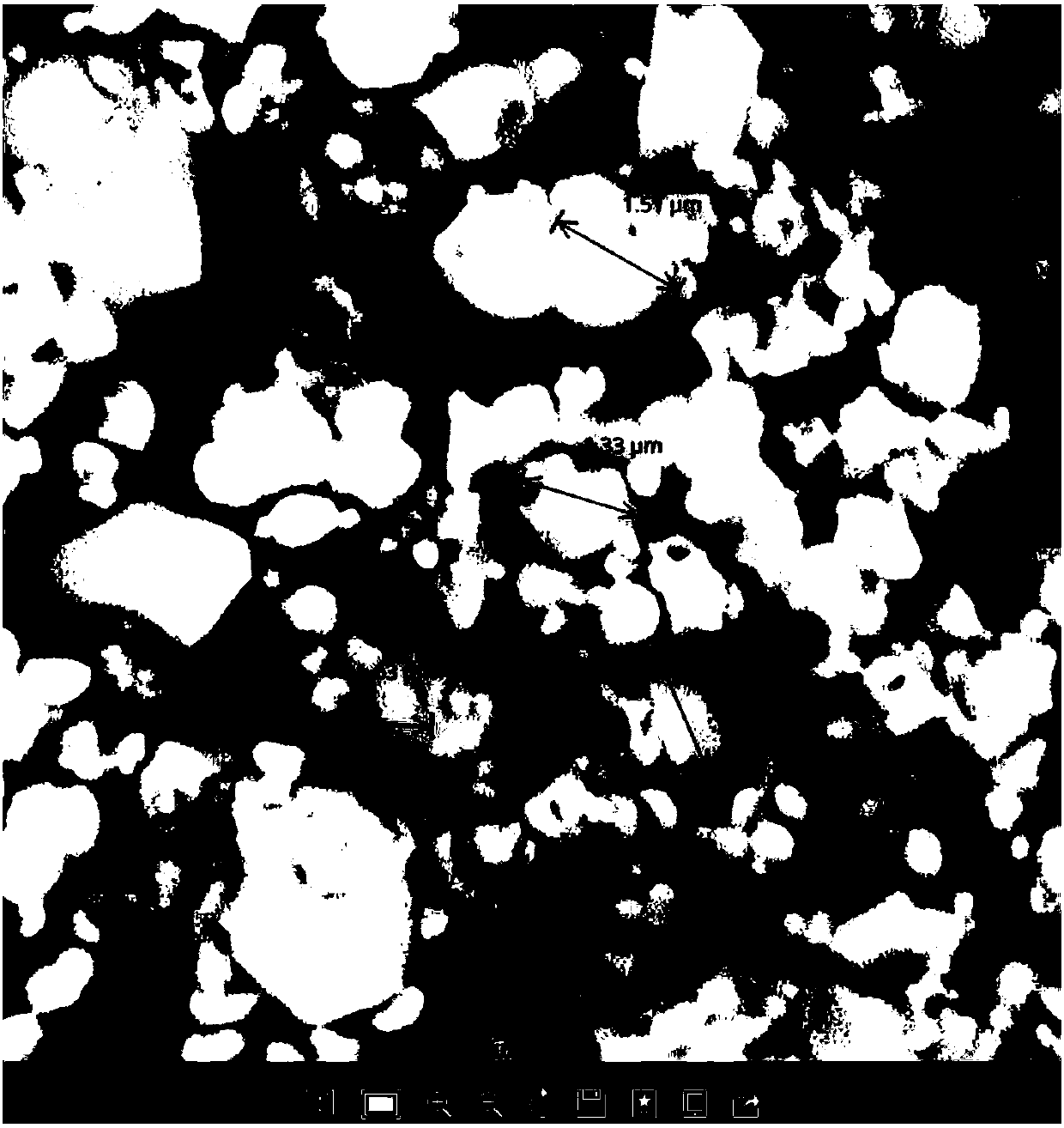

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com