A kind of vegetable oil and organosilicon composite modification, UV-curable nano silicon dioxide, preparation method and application thereof

A nano-silica and vegetable oil modification technology, which is applied in dyeing organosilicon compound treatment, chemical instruments and methods, dyeing polymer organic compound treatment, etc., to achieve the effect of improving hardness, delicate hand feeling and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

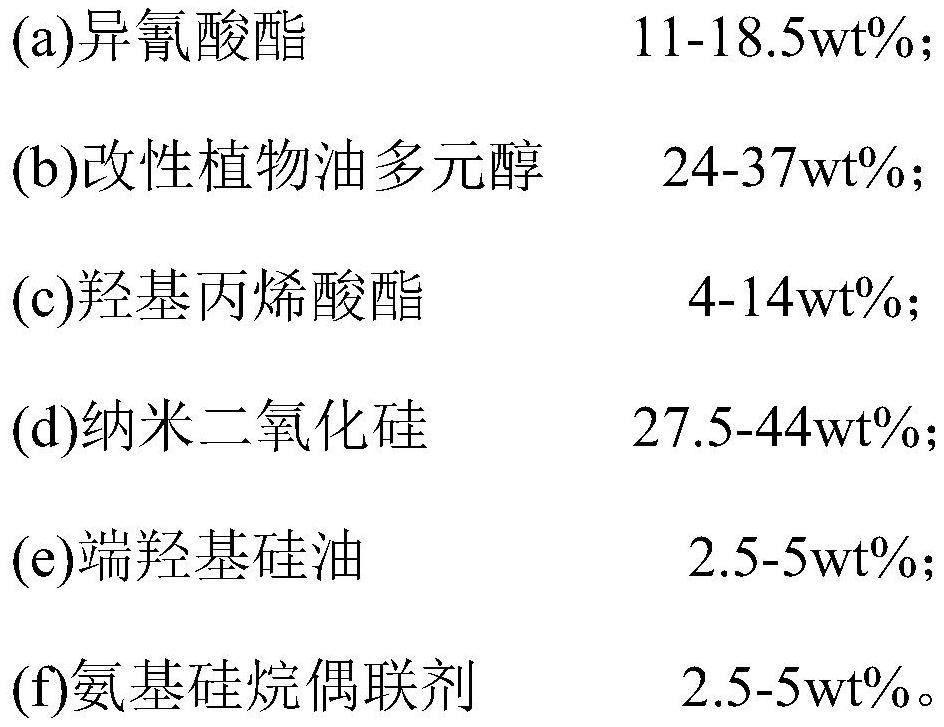

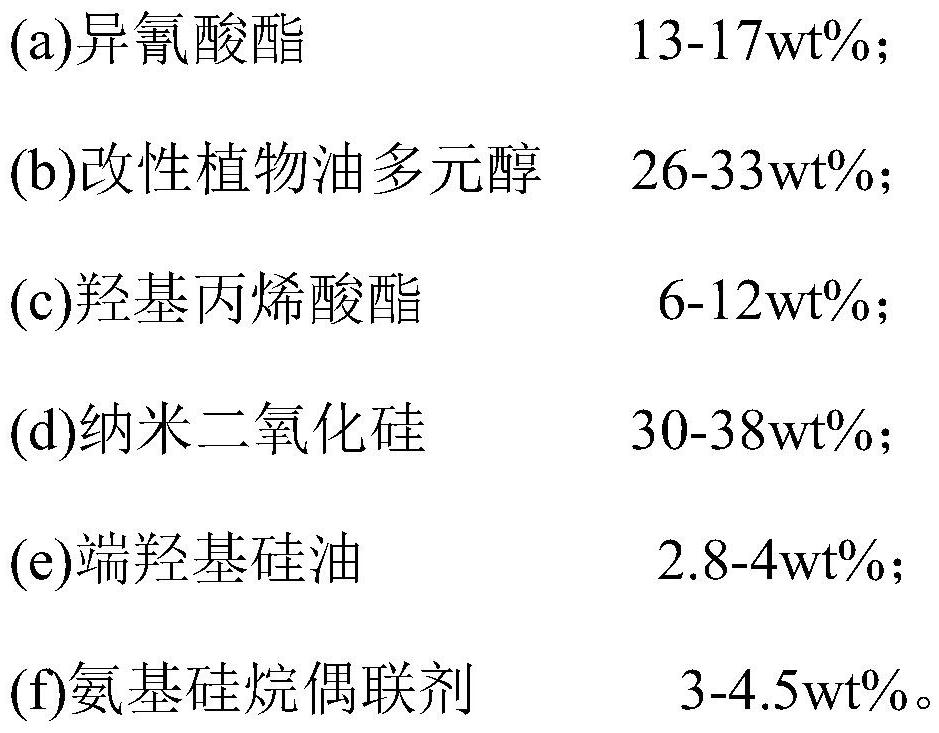

Method used

Image

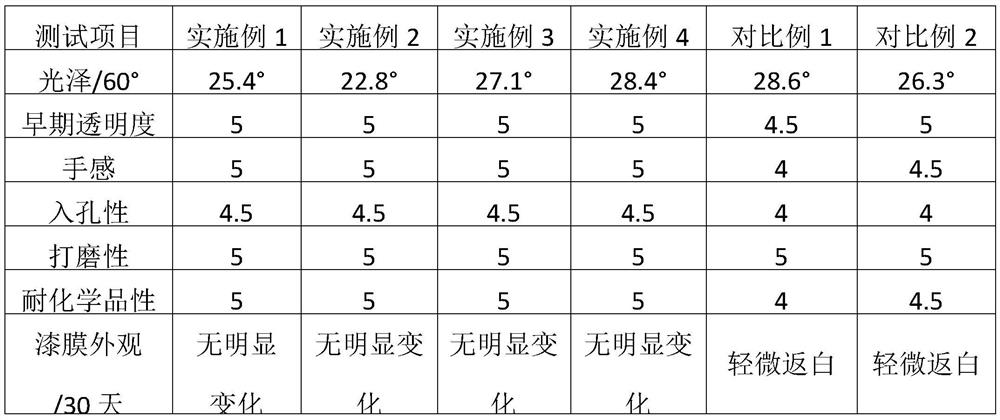

Examples

preparation example Construction

[0036] Specifically, the preparation method of composite modified nano silicon dioxide of the present invention comprises the following steps:

[0037] (1) at 35-55°C, preferably at about 45°C, place the aforementioned stoichiometric components (a), (b) and an appropriate amount of solvent acetone in a reactor to react to prepare a vegetable oil modified prepolymer;

[0038] (2) Raise the temperature to 65-75°C, add the aforementioned component (c) and an appropriate amount of solvent acetone into the reaction kettle, continue the reaction until the remaining NCO content reaches the theoretical value, stop the reaction, and remove the acetone to obtain acrylic acid Ester half-capped vegetable oil modified prepolymer, spare;

[0039] (3) Disperse the components (d) and (e) in the aforementioned metered ratio in the solvent n-heptane for 1h, and let it stand for 2d to obtain the silicone surface-modified silica, dry it and redisperse it in ethanol , adding the component (f) in ...

Embodiment 1

[0044] (1) 12g of dehydrated isophorone diisocyanate, 24g of castor oil and 15g of acetone were added to a 1L four-necked round bottom flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 45°C until the NCO reached 5.82wt %.

[0045] (2) Heat up to 70° C., add 8.1 g of pentaerythritol triacrylate and 12 g of acetone, continue to stir and react until NCO reaches 2.46 wt %, remove acetone, and prepare a semi-blocked prepolymer for later use.

[0046] (3) Add 20g of nano-silica with a hydroxyl content of 4.4mmol / g and 450g of n-heptane into a 1L four-neck round bottom flask, stir for 10min, add 3g of hydroxyl-terminated polydimethylsiloxane, and continue stirring 1h, after stirring, let it stand for 2d, and dry the product after the reaction is over; put the dried nano silicon dioxide in a 5L four-neck round bottom flask, add 3000g of absolute ethanol and ultrasonically disperse evenly; Add 30ml of acetic acid aqueous solution (pH value is 4.5) to the ...

Embodiment 2

[0049] (1) Add 10 g of dehydrated isophorone diisocyanate, 18 g of soybean oil alcoholyzate and 12 g of acetone into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and stir the mixture at 50°C until NCO up to 6.75 wt%.

[0050] (2) Heat up to 75°C, add 2.93g of hydroxyethyl methacrylate and 10 grams of acetone, continue to stir and react until NCO reaches 3.07wt%, remove acetone, and prepare a semi-blocked prepolymer for later use.

[0051] (3) Add 25g of nano-silica with a hydroxyl content of 4.2mmol / g and 400g of n-heptane into a 1L four-neck round bottom flask, stir for 10min, add 2g of hydroxyl-terminated polydimethylsiloxane, and continue stirring 1h, after stirring, let it stand for 2d, and dry the product after the reaction; put the dried nano-silica in a 5L four-neck round bottom flask, add 2500g of absolute ethanol and ultrasonically disperse it evenly; Add 20ml of acetic acid aqueous solution (pH value is 4.5) to the dispersion at ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com