Preparation methods and applications of menthofuran molecular imprinted polymer and monolithic column

A mint furan and molecular imprinting technology, which is applied in chemical instruments and methods, other chemical processes, organic chemistry, etc., can solve the problems that the maximum usage amount and the allowable residue amount are not clearly stipulated, and achieve good and fast molecular recognition performance. The mass transfer rate and the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

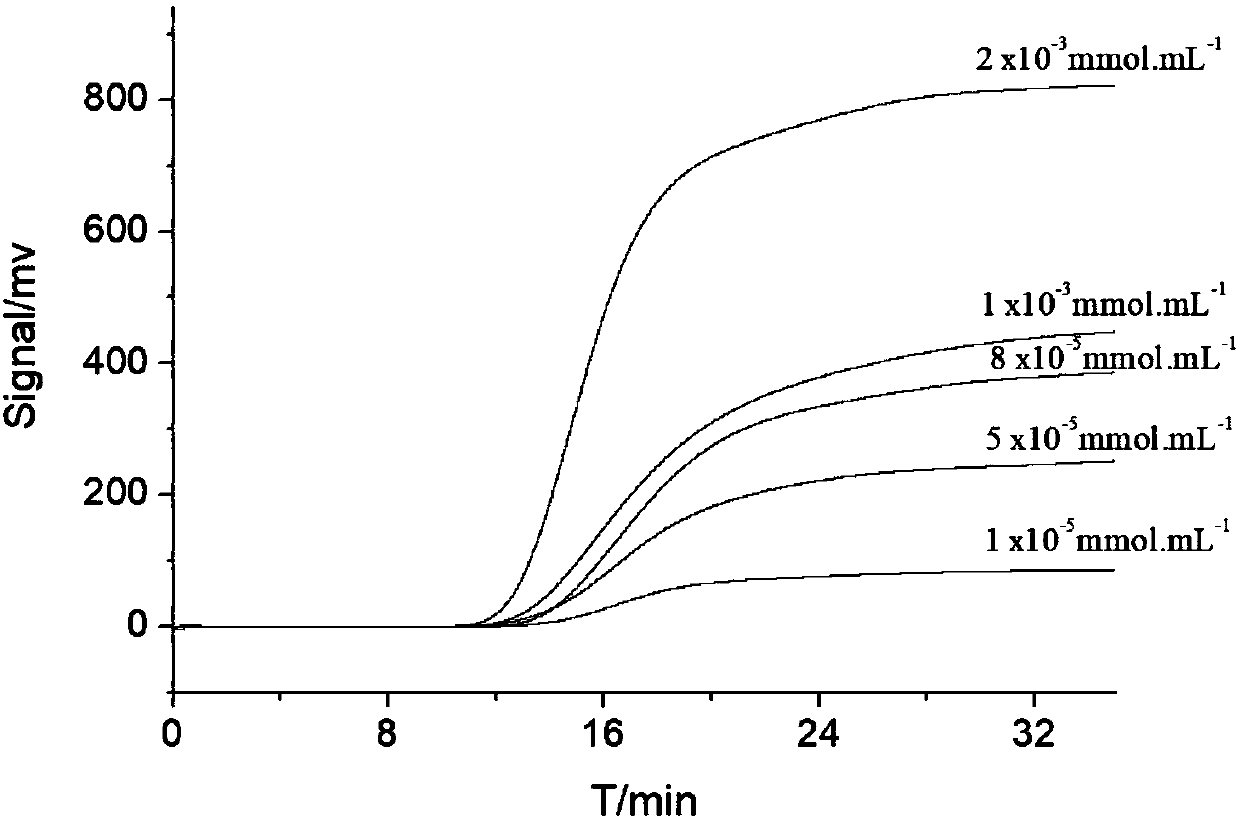

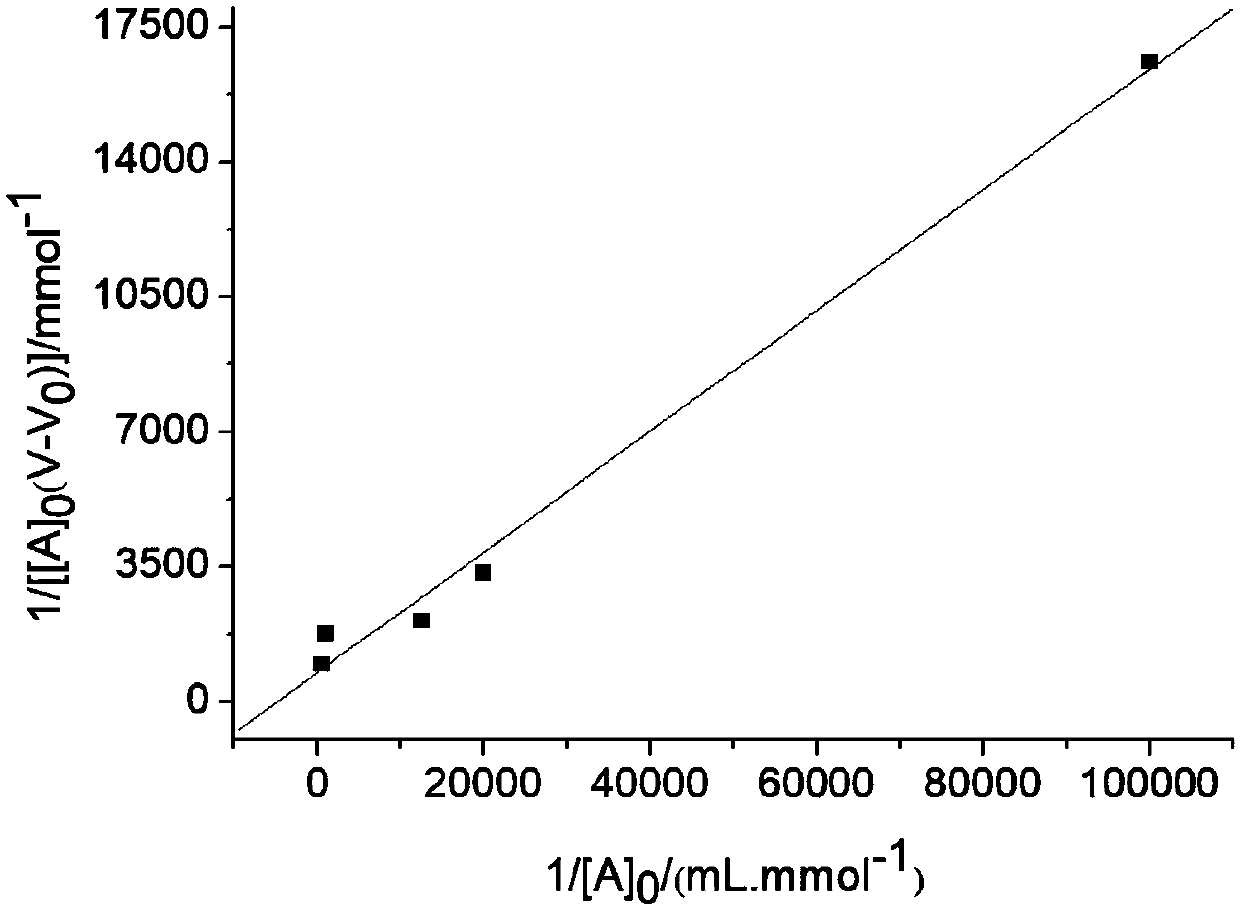

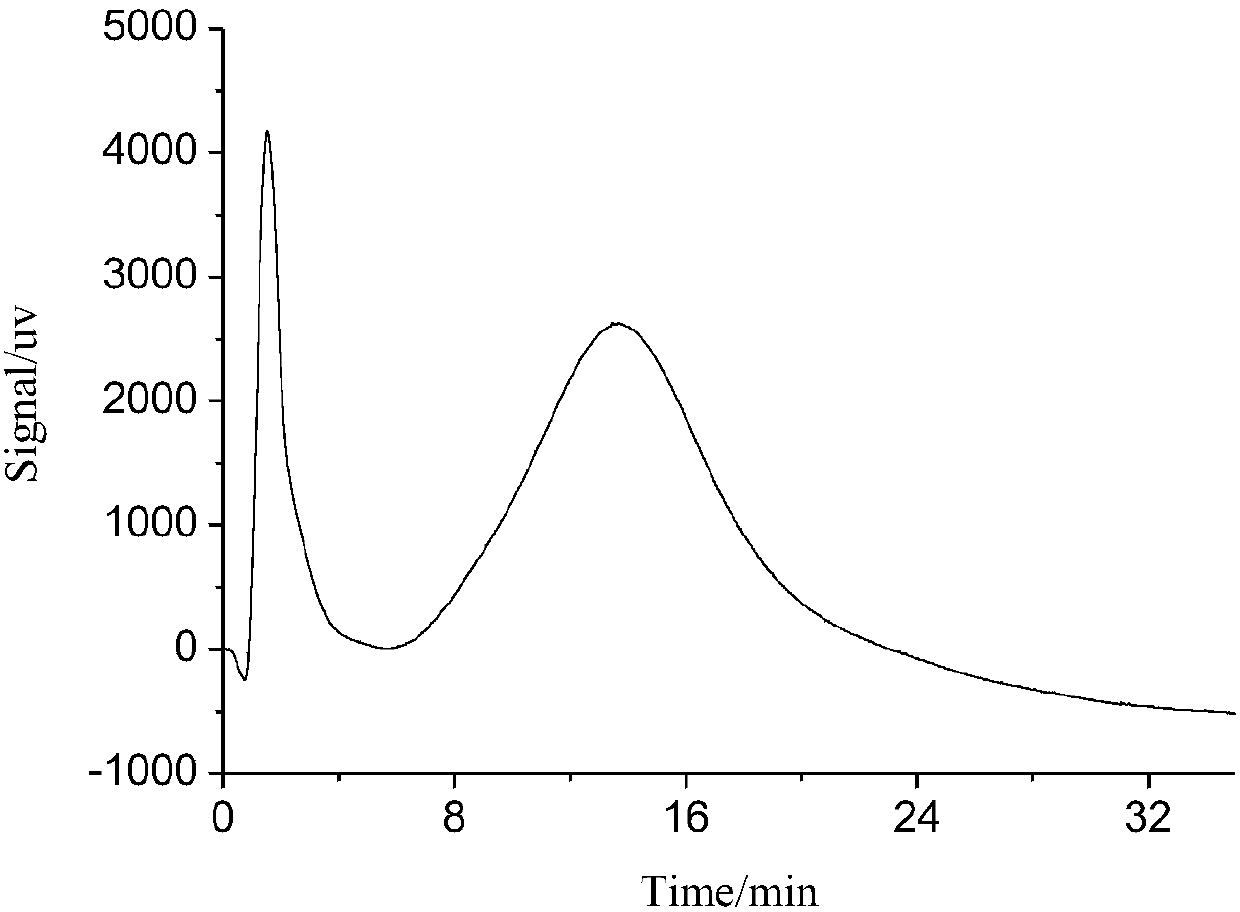

[0055] First, dissolve 0.34mmol of the template molecule menthafuran in the porogen toluene / dodecanol (1.89:1.74), add 1.36mmol of the functional monomer methacrylic acid, and 5.1mmol of the crosslinking agent ethylene glycol dimethacrylate , the initiator azobisisobutyronitrile 11 mg was mixed and ultrasonically treated for 15 minutes, and then nitrogen gas was passed for 15 minutes. The solution was injected into a stainless steel chromatographic column (150 mm × 4.6 mmi. The reaction was carried out in a 55°C oven for 24 hours, and thermally initiated to obtain a molecularly imprinted monolithic column. Connect the column to the LC pump with methanol / KH 2 PO 4 (Volume ratio 50 / 50, pH=8) and methanol / water (95 / 5, v / v) cleaning solution to remove the template molecules to obtain the monolithic column (MIP1) of mint furan molecularly imprinted.

Embodiment 2

[0057] Dissolve 0.34 mmol of the template molecule menthol furan in the porogen toluene / dodecanol (2.27:10.36), sonicate in an ice-water bath for 15 minutes, blow nitrogen for 10 minutes, and put it in an oven at 55°C for 24 hours. Others are the same as in Example 1. , and the monolithic column (MIP2) of mentha furan molecularly imprinted can be obtained.

Embodiment 3

[0059] Dissolve 0.34 mmol of the template molecule menthol furan in the porogen toluene / dodecanol (3.415:19.355), 3.4 mmol of the cross-linking agent ethylene glycol dimethacrylate, sonicate for 20 minutes in an ice-water bath, and blow nitrogen for 10 minutes. Put it in an oven at 55° C. for 24 hours, and the others are the same as in Example 1 to obtain a monolithic column (MIP3) of menthafuran molecularly imprinted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com