Vortex spinning sportswear fabric

A technology of vortex spinning and fabrics, which is applied to textiles, papermaking, yarn, weft knitting, etc. It can solve the problems of poor wearing comfort, poor moisture absorption and perspiration performance, and achieve good thermal conductivity, good bulkiness, and good heat preservation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

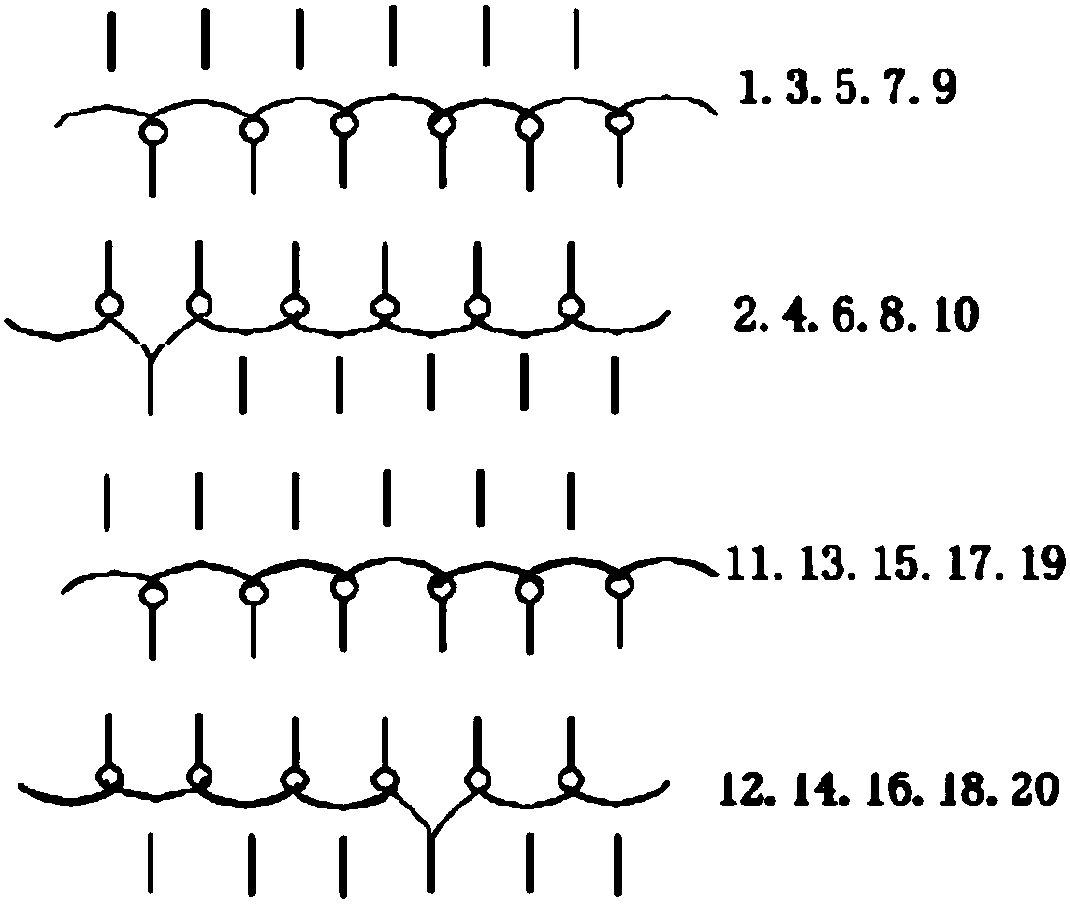

[0015] combine figure 1 , the invention discloses a vortex spinning sports fabric, which includes a fabric body. The main body of the fabric adopts a double-sided fish-eye structure, the reverse side is elongated and mesh-shaped, and the front side is flat-shaped. The inner thread of the fabric body has a large fineness, forming a thick capillary structure, and the outer thread of the fabric body has a small fineness, forming a fine capillary structure; the outer thread is a blended vortex yarn of hemp fiber and wool fiber; The inner layer silk thread is a hollow core-spun yarn.

[0016] The inner layer silk thread can adopt the vortex spinning process, use the water-soluble PVA filament as the core yarn, and use cotton fiber and polyester staple fiber as the wrapping fiber to make the vortex spinning core-spun yarn; then the water-soluble PVA filament is hydrolyzed Processed to make the inner silk thread. That is, the inner layer silk thread includes a hollow core layer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com