S-CO2 power generation system and method for developing geothermal energy of hot dry rock based on finned casing pipe

A power generation system, S-CO2 technology, applied in geothermal energy power generation, geothermal energy systems, geothermal energy, etc., to achieve the effects of increasing single well output, avoiding leakage, and low corrosion and scaling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

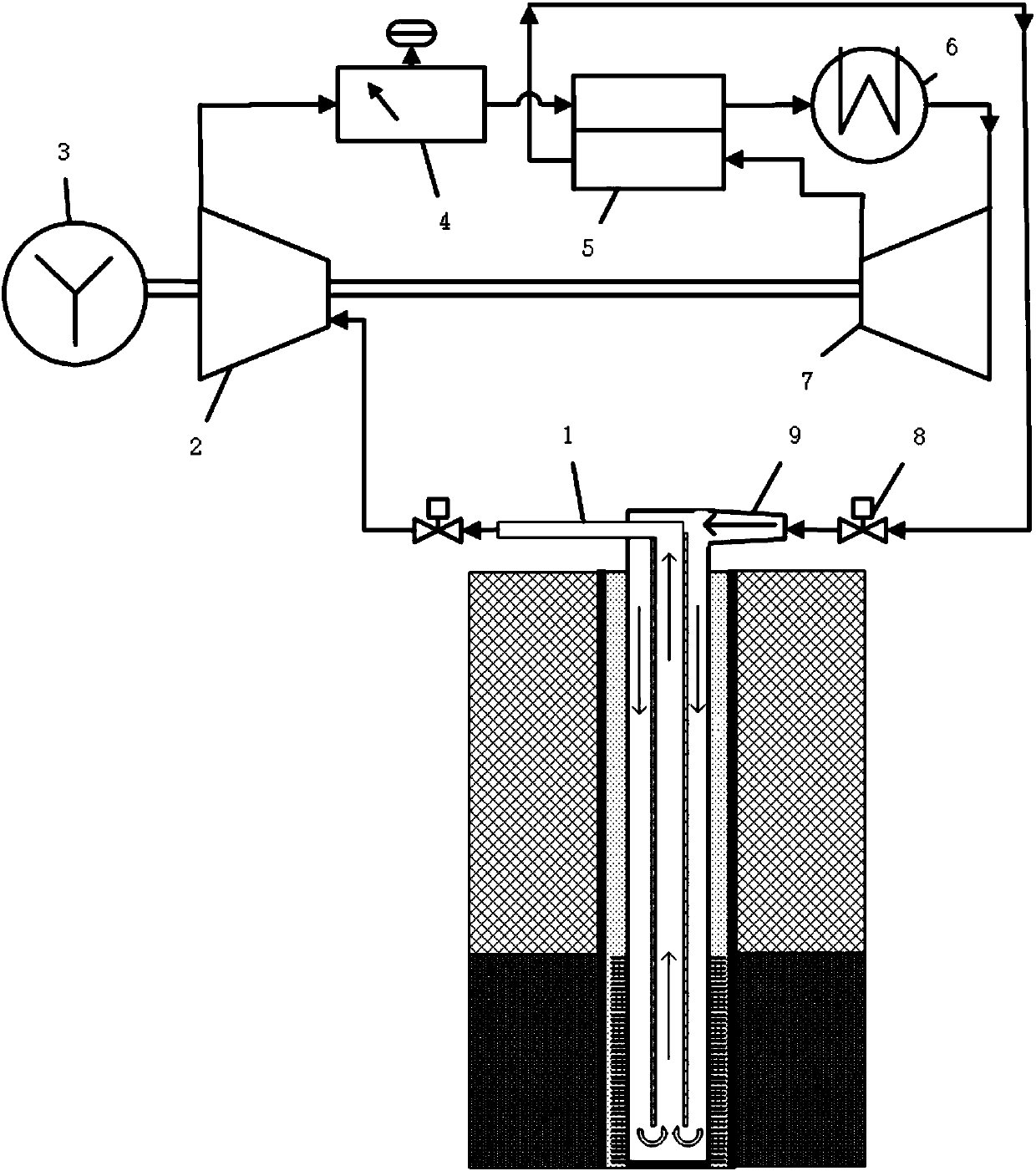

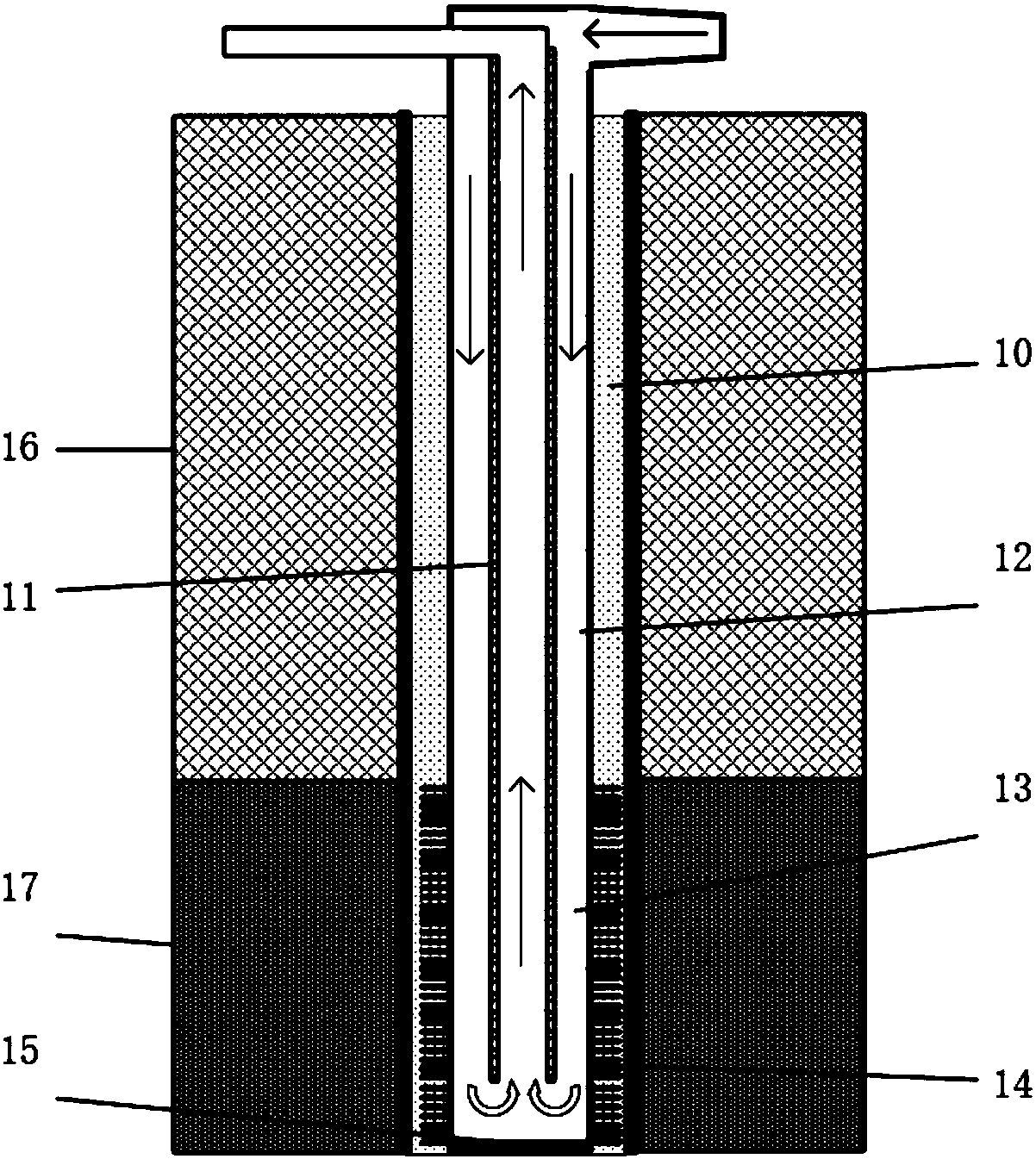

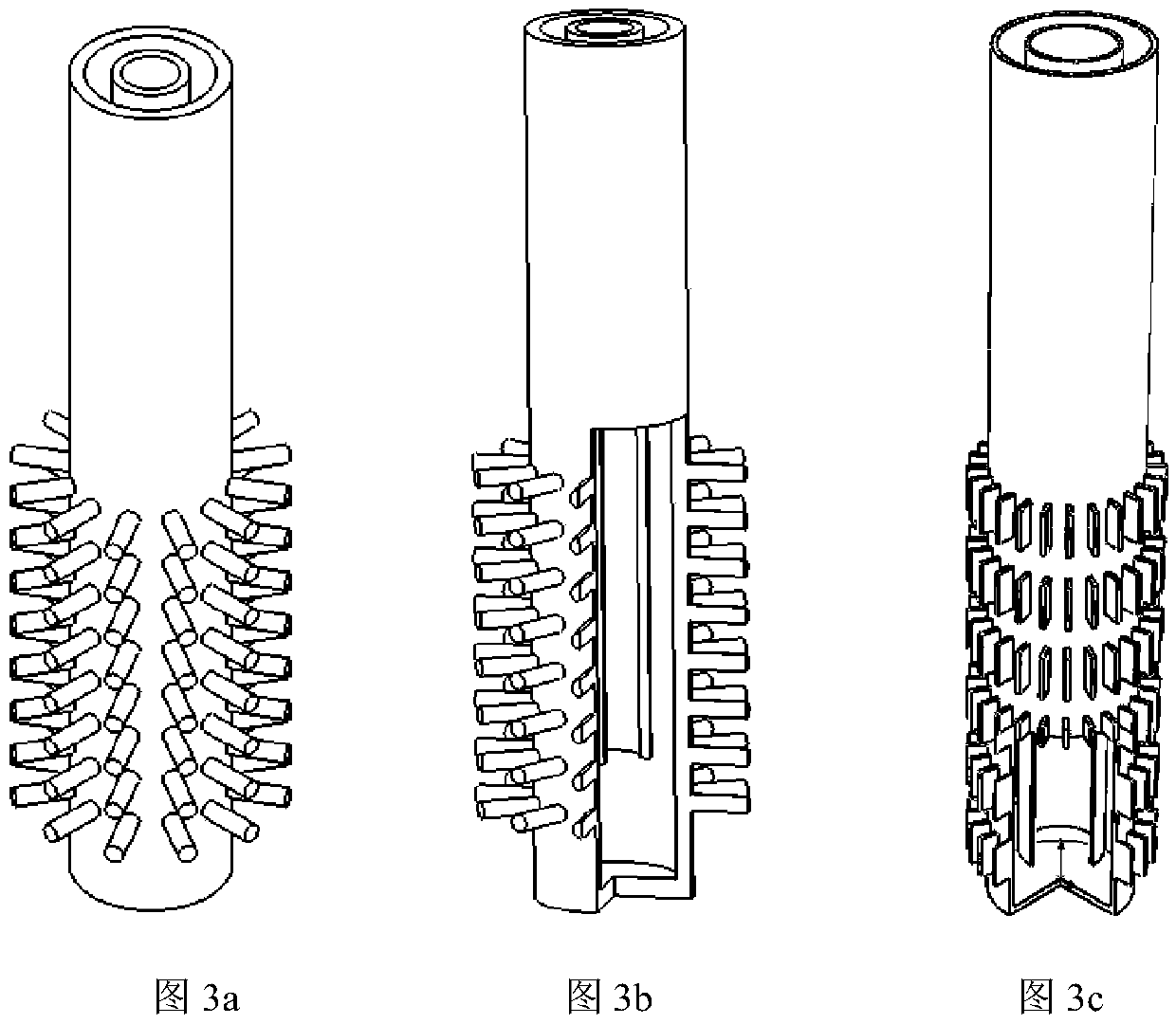

[0036] Such as figure 1 As shown, the S‐CO 2 Power generation system and method, the system consists of internal return pipe 1, S-CO 2 Gas turbine 2, generator 3, working fluid detection unit 4, regenerator 5, condenser 6, compressor 7, valve 8, outer layer descending pipe inlet 9, etc.; the system composition form is as follows: the compressor 7 will CO 2 compressed to a supercritical state and powers the CO 2 After being preheated by the regenerator 5, it enters the inlet 9 of the outer descending pipe section, and the valve 8 can cooperate to adjust the flow rate and pressure of the circulating working medium; the circulating working medium flows downward in the outer tube of the fin casing and absorbs rocks and hot dry rocks The heat in the heat is gathered to the inner return pipe 1 at the bottom of the heat extraction well; the heated circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com