Large rolling suction jet burn-off air system and spray method

A technology of burn-out wind and high-speed jet, which is applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of reducing nitrogen oxides, high carbon content in fly ash, and damage to reduction zones, so as to reduce the concentration of carbon monoxide and reduce fly ash. Ash carbon content, effect of reducing nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

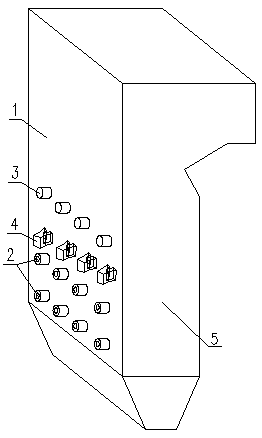

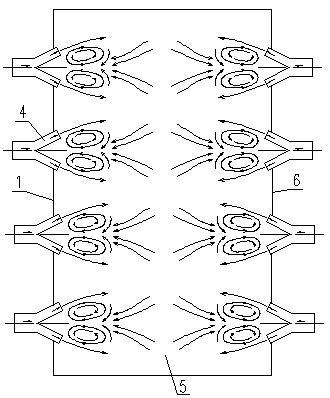

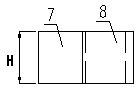

[0021] like Figure 2 to Figure 4 As shown, the large entrainment jet burn-off air system of the present embodiment includes a furnace 5, a top burn-off air nozzle 3 on the front wall 1 and a rear wall 6 of the furnace 5, and the top burn-off air nozzle 3 and the main Both the front wall 1 and the rear wall 6 between the burners are provided with two layers of overburning air nozzles, each layer of overburning air nozzles includes several overburning air nozzles 4, and the overburning air nozzles 4 on the front wall and the rear wall It is a Y-shaped entrainment jet burn-off air nozzle. The nozzle 4 includes an air inlet pipe 7 and two air outlet pipes 8 connected to each other. The aspect ratio H / K is 1-6; the angle α between the two air outlet pipes and the center line of the air inlet pipe is 5°-45°;

[0022] The injection method for the above-mentioned large entrainment jet burn-off air system includes the following steps: inject several strands of burn-off air in four la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com