Spotting tooling for thermal vacuum test

A thermal vacuum test and tooling technology, which is used in thermometers and measuring devices that use electrical devices, electrical/magnetic components that are directly sensitive to heat, etc. Simple structure, easy to use and reliable, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] For the sake of convenience only, in the following description, specific directional terms, such as "up", "down", etc., are used with reference to the corresponding drawings, and should not be regarded as limiting the present invention. Where the defined orientation of the drawing is changed, the orientation indicated by these words shall be interpreted as a corresponding different orientation.

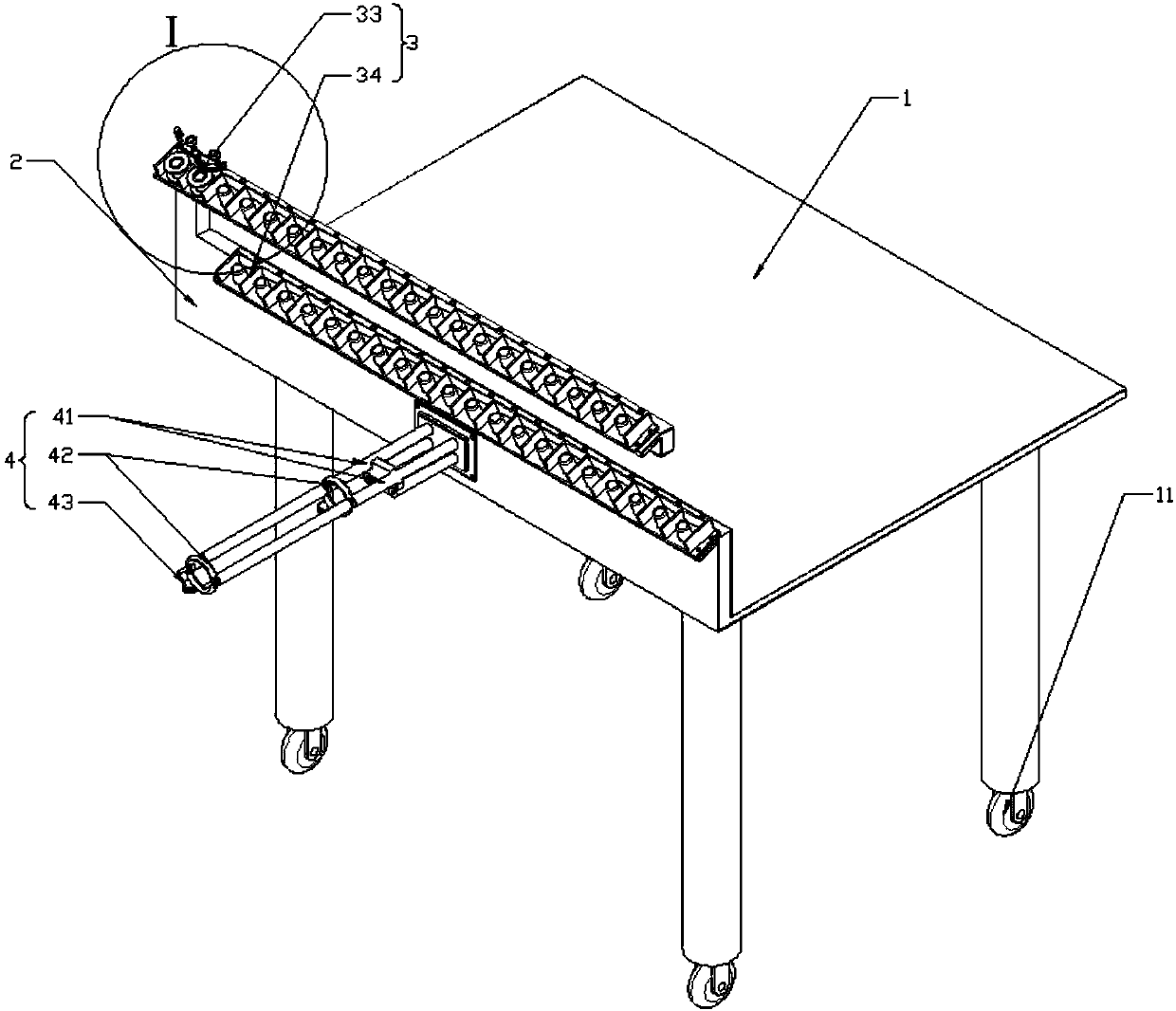

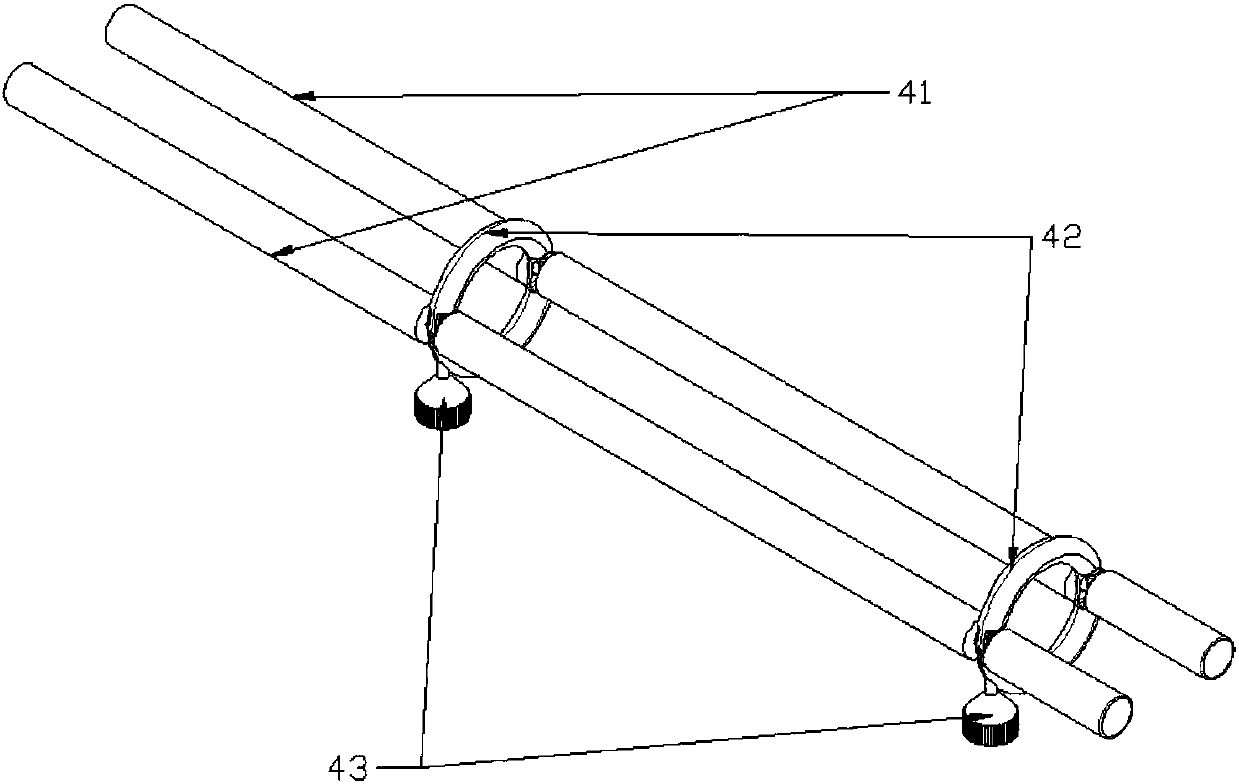

[0034] Such as figure 1 The shown a point layout tool for thermal vacuum test, including a workbench 1 with walking wheels 11, a bracket 2 installed on the workbench 1, and a bobbin frame 3 fixedly arranged on the bracket 2 from top to bottom and wire support assembly4.

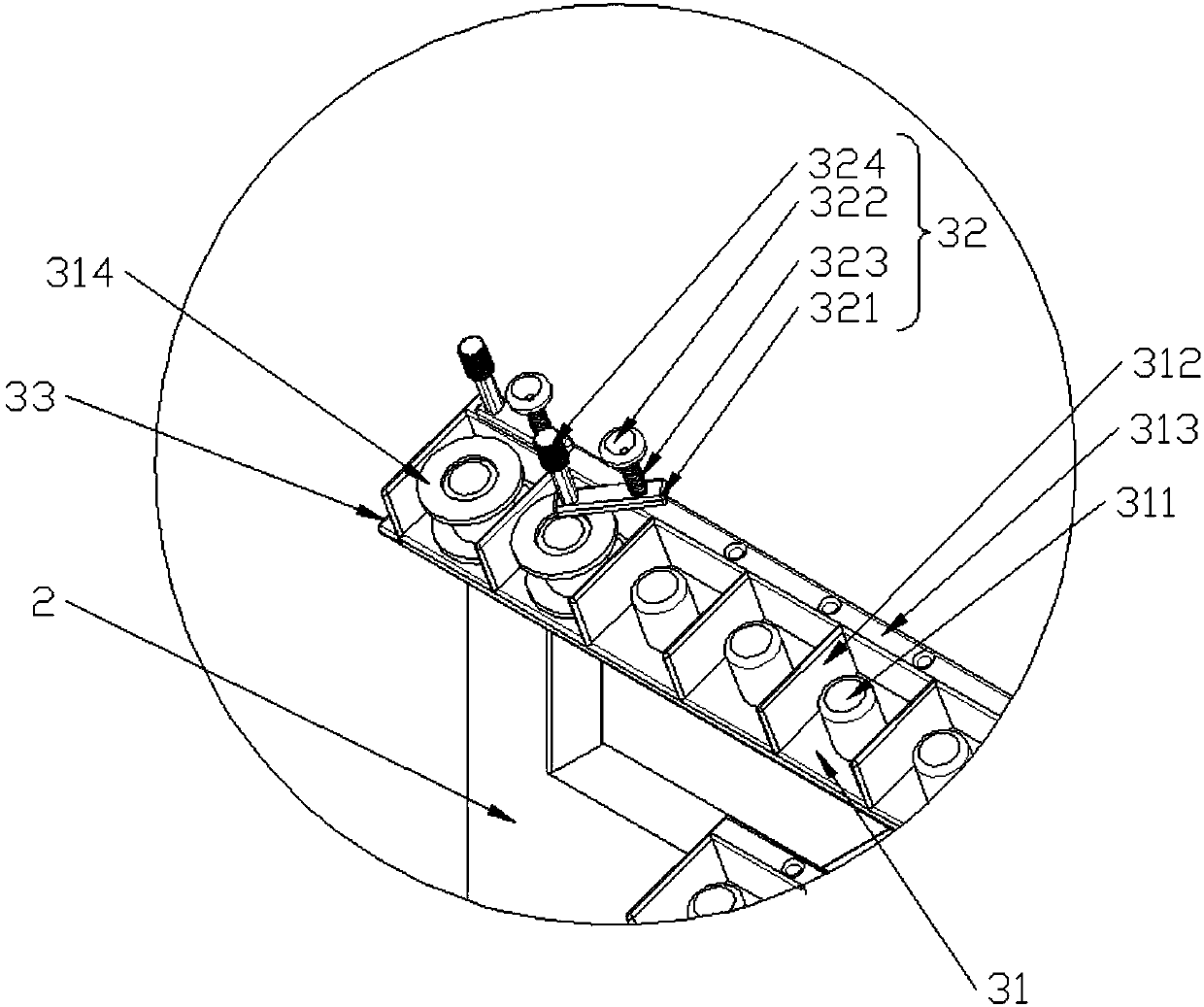

[0035] The creel 3 includes a first creel 33 and a second creel 34 in the form of horizontal strips, which are arranged in upper and lower layers. Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com