Intelligent control system based on biological fiber carbonization

An intelligent control system and bio-fiber technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as poor automation, manual input, cumbersome and inconvenient operations, and achieve high energy utilization and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

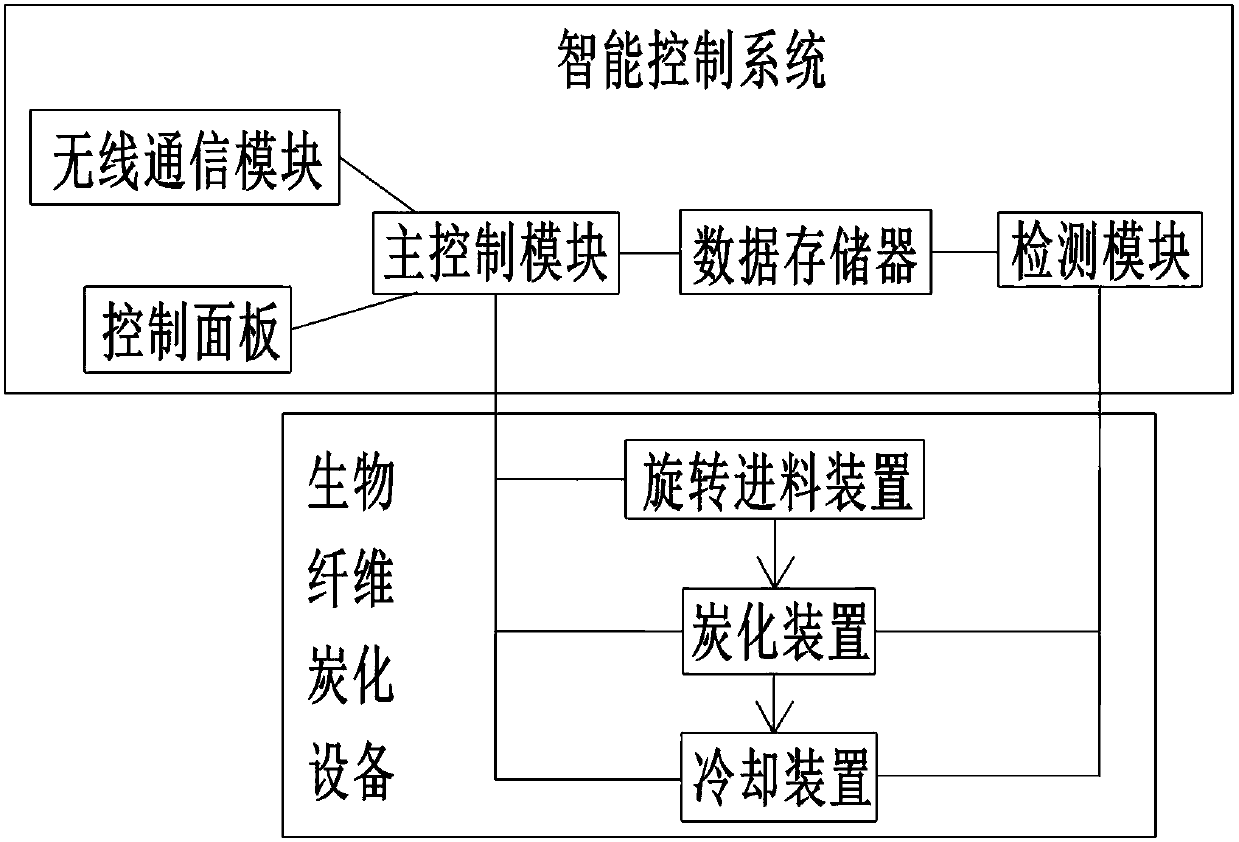

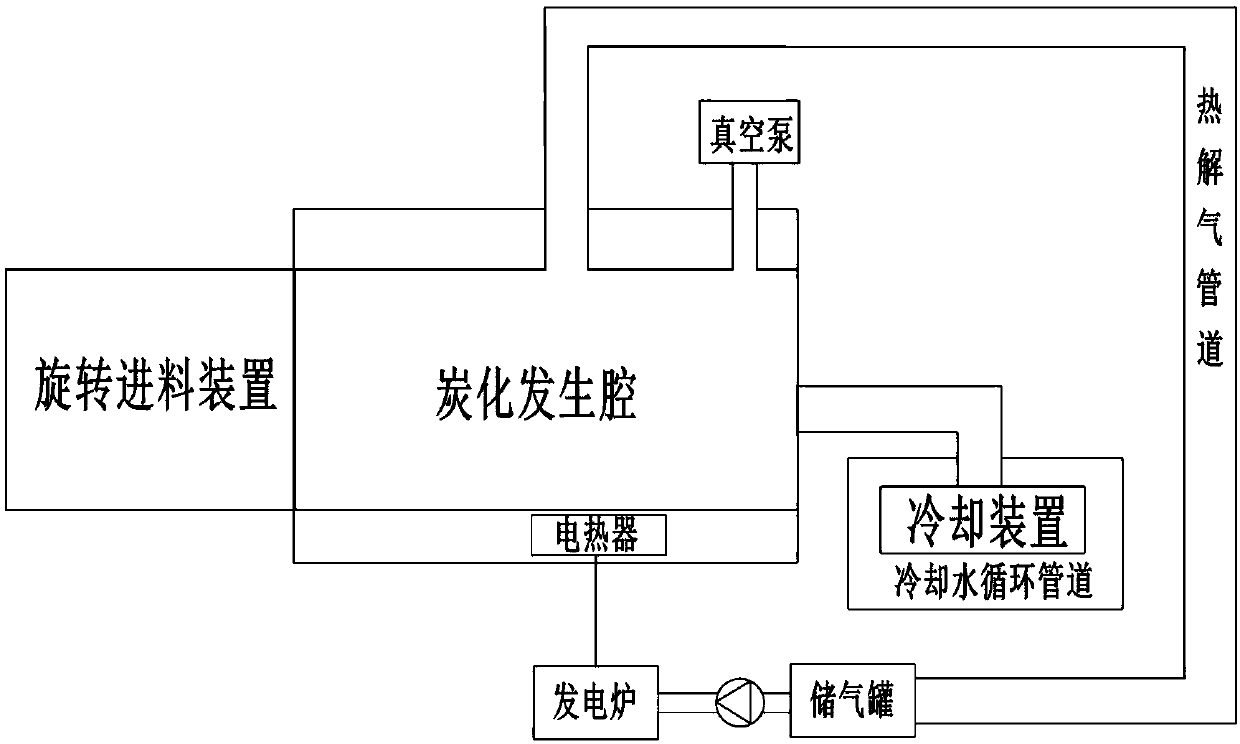

[0018] Implementation Case 1: Please refer to figure 1 , an intelligent control system based on biological fiber carbonization, including biological fiber carbonization equipment and an intelligent control system, the biological fiber carbonization equipment includes a rotary feeding device, a carbonization device and a cooling device connected in sequence; the intelligent control system includes a main Control module, detection module, data memory, wireless communication module and control panel;

[0019] The main control module is connected with the rotary feeding device, the carbonization device and the cooling device, and is used to control and set the rotary feeding speed of the rotary feeding device, the heating rate, the carbonization temperature and the carbonization time of the carbonization device, and the cooling The cooling time of the device and the temperature of the cooling carbon;

[0020] The detection module is connected with the carbonization device and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com