Underground utility tunnel region controller and work method thereof

A technology for area controllers and integrated pipe corridors, which is applied in the direction of program control, program control, and electrical program control in sequence/logic controllers, and can solve problems such as high equipment cost, increased processing pressure on the upper computer, and high technical threshold. Achieve the effects of reducing space occupation, reducing difficulty in use, and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] It should be pointed out that the following detailed description is exemplary and intended to provide further explanation to the present application. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

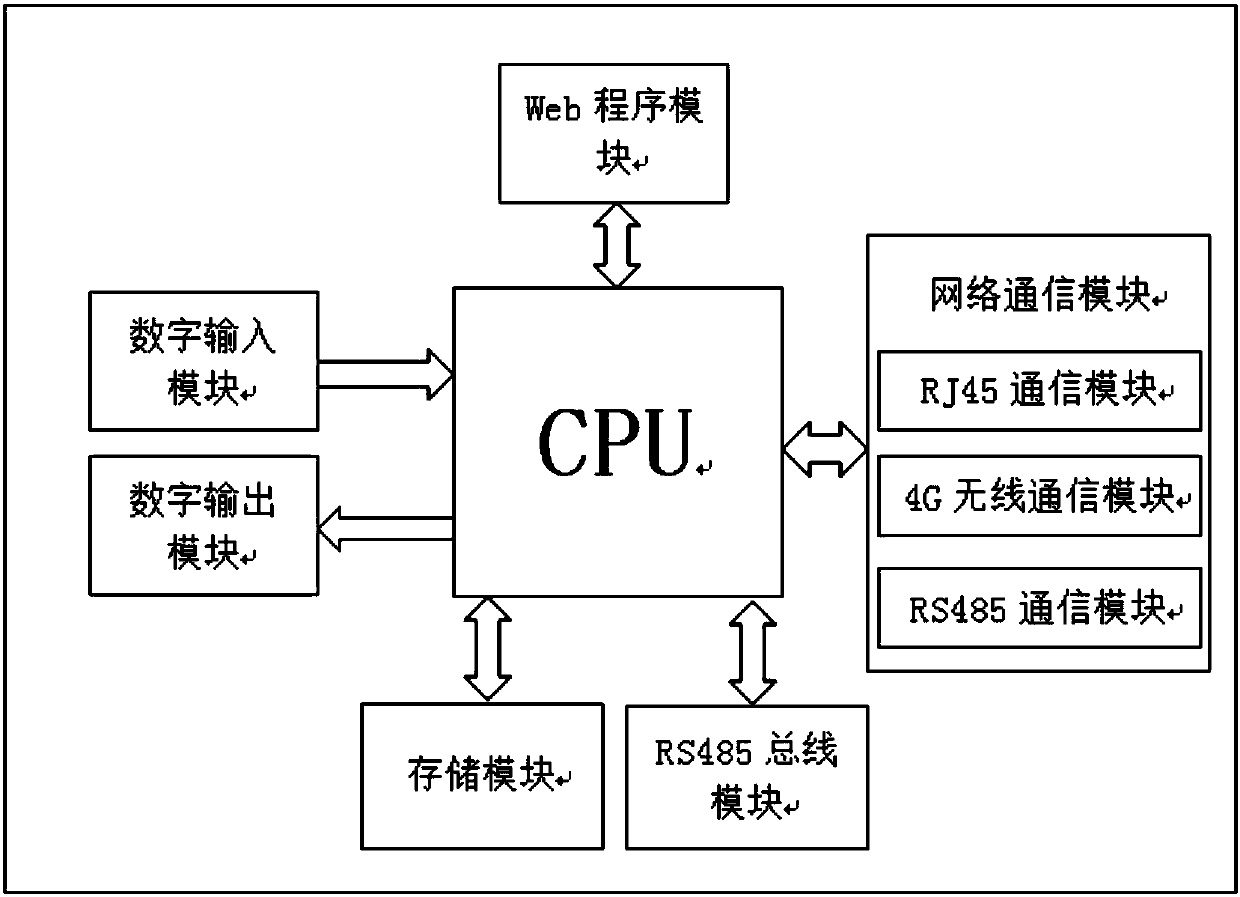

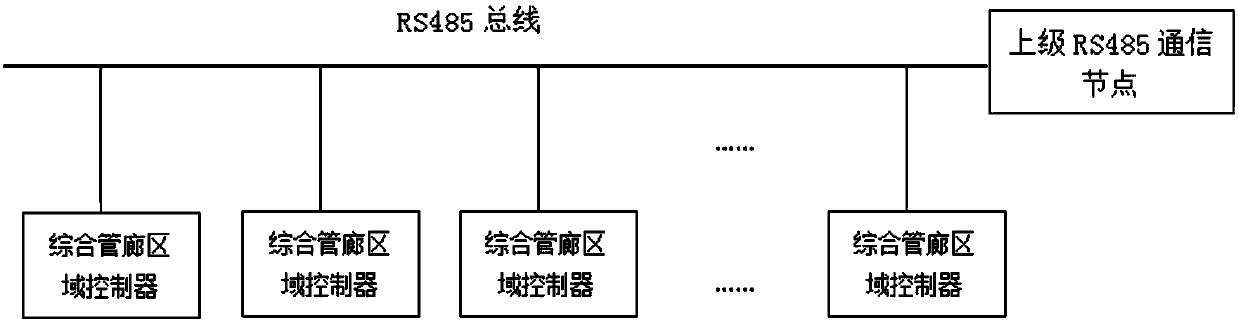

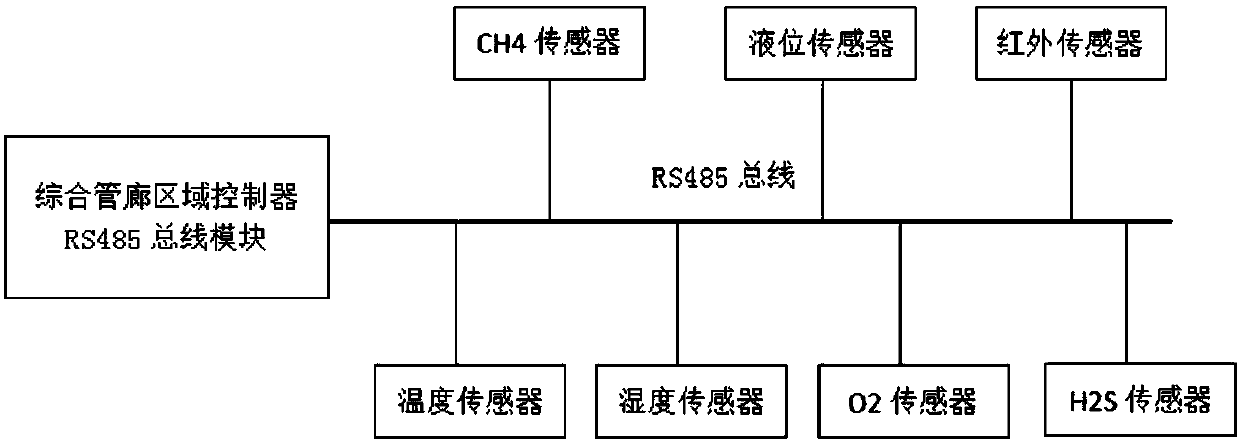

[0063] Such as figure 1 , The regional controller of the underground integrated pipe gallery, including: the central processing unit CPU and 16 digital input modules connected to it, 8 digital output modules, storage modules, 1 RS485 bus, network communication module, Web server, etc. The RS485 bus is connected to the temperature sensor, humidity sensor, CH4 sensor, O2 sensor, H2S sensor, etc. in the pipe gallery, using the standard MODBUS communication protocol, and using the same baud rate to connect to the regional controller of the underground comprehensive pipe gallery through the RS485 bus.

[0064] The web server provides web m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com