A railway equipment tracking management system

A management system and equipment technology, applied in the field of tracking management system, can solve the problems of inconvenient production and maintenance, underutilization of computer technology, failure to grasp the service life of parts in time, and achieve the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

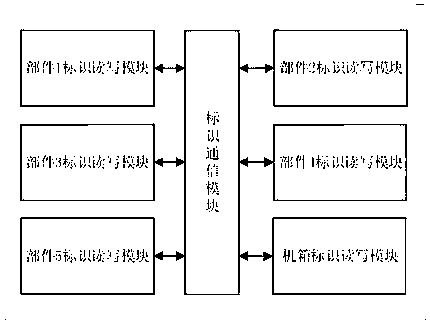

[0061] Take an in-vehicle device (hereinafter referred to as SN1) as an example. SN1 includes a power supply board, a signal acquisition board, a control output board, a driving record board, a backplane (providing an interface between boards), a chassis and other components. Each board and There are identification storage modules on the chassis, and besides the identification storage modules on the driving record board, there are identification read-write modules and identification communication modules. In this embodiment, CAN communication is adopted for all vehicle-mounted equipment components, and 4G communication is adopted for vehicle-mounted equipment, device server, and management system; the memory of all identification storage modules adopts EEPROM; all tags adopt the form of two-dimensional code plus electronic label , Are collectively referred to as tags in this embodiment; the management system is installed on the PC; the cable connection of the device is not the m...

Embodiment 2

[0076] 1. In the management system, query the information record of the board by entering the board card identification information or scanning the board card identification information, such as board maintenance information, work information, working years, etc.;

[0077] 2. You can send query instructions (such as CX+ board card identification information) to the server through mobile phone text messages to query board information records;

[0078] 3. In the management system, establish a three-dimensional model of the device, click on a part of the device and pop up all the registered logos of that part, and select any of the logos for visual query;

[0079] 4. The server pushes maintenance reminders to maintenance personnel or users according to the production date of equipment or components and the date of first installation in accordance with the corresponding maintenance procedures. For example, it is stipulated that ventilation and power supply are required for storage for thr...

Embodiment 3

[0081] On the basis of the above embodiment 1, the fault information can be inquired and managed:

[0082] 1. Server self-learning fault location: The server compares the meaning of the fault code with the maintenance record, and sorts the number of faults that occur under a certain fault code. When a new fault is found, it will compare the current fault according to the historical record data. The code and possible devices are automatically pushed to maintenance personnel or users through (not limited to) emails, short messages, or pop-up windows in the management system; for example, the STEP6 fault code CTR01 in Example 1 indicates that the control part is faulty, and the historical maintenance records are collected and controlled. If the number of relay failures in the circuit is 10, the number of diode failures is 2, and the number of capacitor failures is 0, then the push message is: failure code CTRO1, control circuit failure. The devices that may fail are relays, diodes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com