Passive Q-switched Nd:YAG intra-cavity 1570nm OPO laser

A technology of lasers and inner cavities, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of low light-to-light conversion efficiency and difficulty in miniaturization, and achieve compact structure, reduced volume, and electro-optic efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

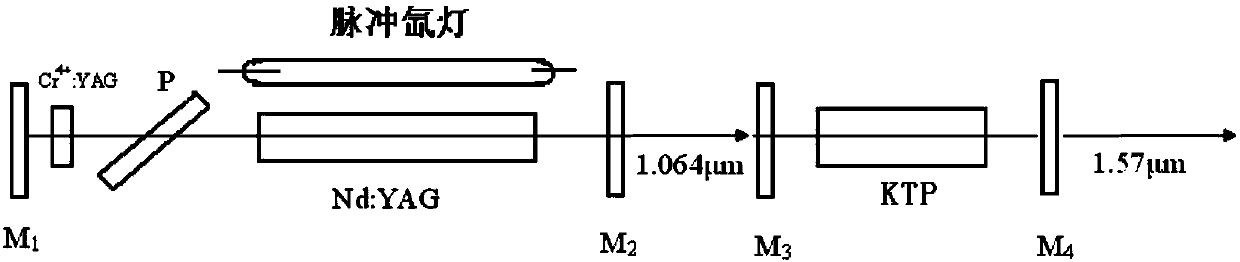

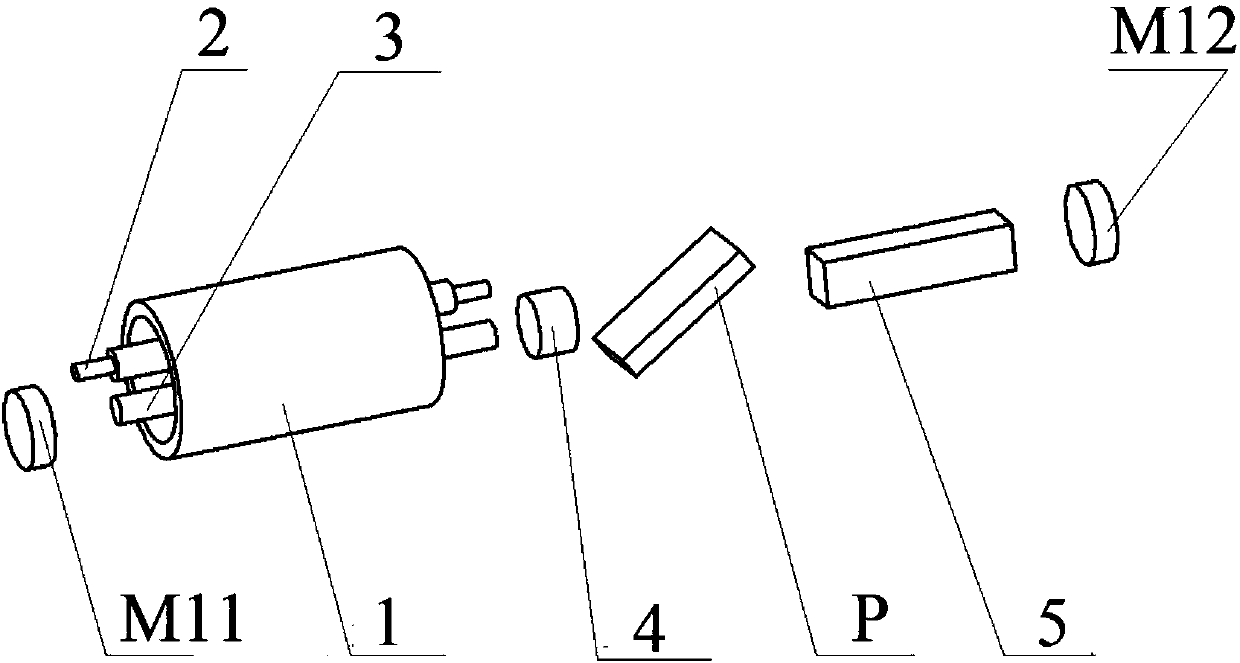

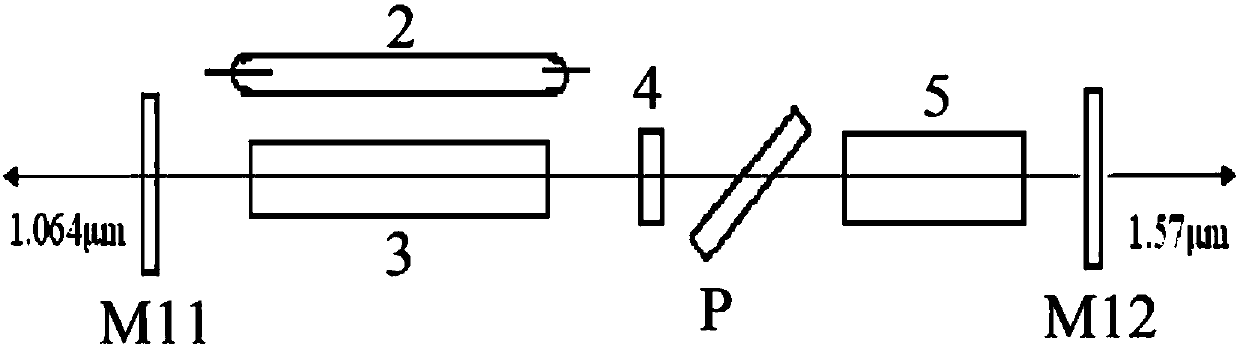

[0024] Such as figure 2 and image 3 Shown, this example Cr 4+ YAG passively Q-switched Nd:YAG intracavity 1.57μm OPO laser includes: Nd:YAG crystal 3, KTP crystal 5, Cr 4+ : YAG Q-switching crystal 4, polarizer P, planar resonant cavity mirror, diffuse reflection concentrating cavity 1 and pulse xenon lamp 2; pulse xenon lamp 2 and Nd:YAG crystal 3 are located in diffuse reflection concentrating cavity 1, and planar resonant cavity mirror includes 1.064μm output mirror M11 and 1.064μm total reflection and 1.57μm output mirror M12; Nd:YAG crystal 3, Cr 4+ : YAG Q-switching crystal 4, polarizer P, and KTP crystal 5 are coaxially arranged along the optical path direction, the 1.064 μm output mirror M11 is located outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com