Method for constructing economic forest on slit ground terraced fields under steep slope condition in loess geomorphy loess hill landform area

An economic forest and loess technology, applied in the field of ecological environment engineering, can solve problems such as water and soil loss, and achieve the effects of simple construction, improved agricultural production efficiency, and strong vegetation adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

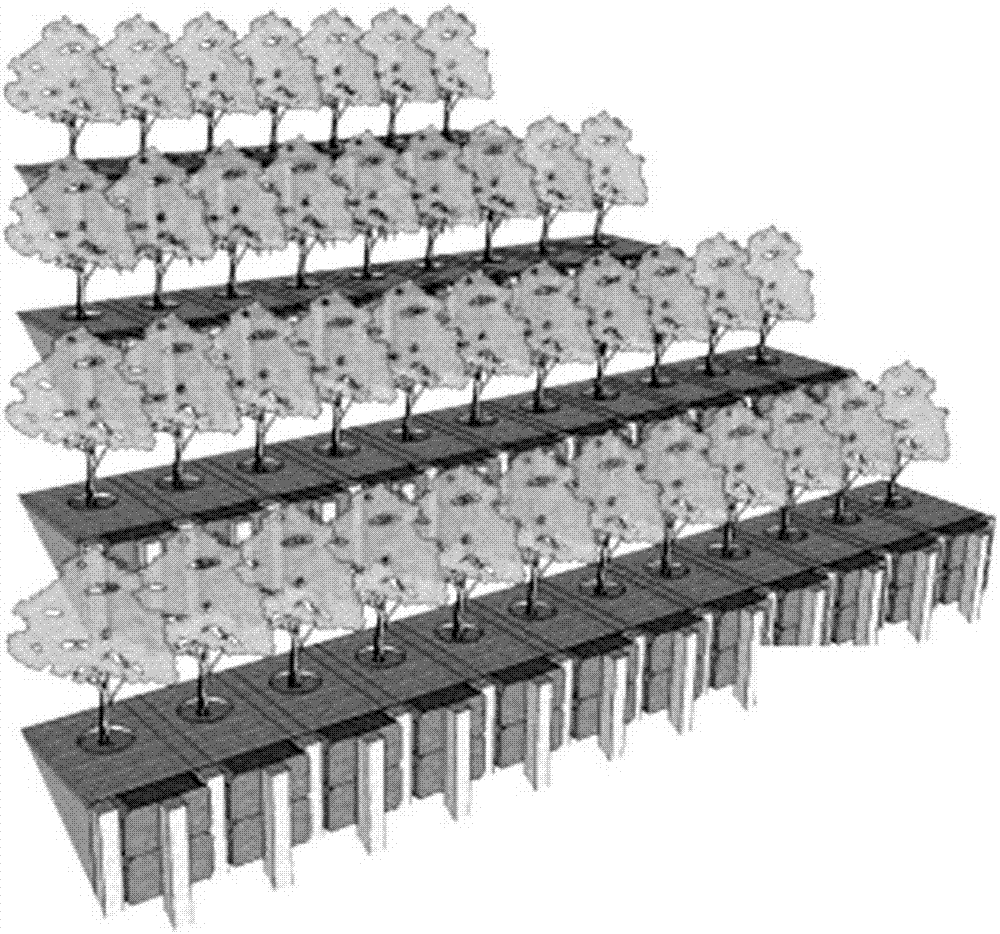

[0051] Such as Figure 1-13 Shown a kind of loess hilly geomorphic area steep slope condition silted land terrace economic forest construction method, comprises the following steps:

[0052] Step 1: prefabricated component one, component one is the reinforced concrete pile 5 that fixed pile is used;

[0053] Step 2: Prefabricate component 2. The component 2 is formed by putting formula loess carrier 6 into mold box 4, formula loess carrier 6 is filled with formula loess, and the formula loess carrier 6 is sealed after compaction.

[0054] Step 3: Assemble and arrange component one and component two;

[0055] Ramming component one prefabricated in step one on the original slope 9, placing prefabricated component two into the gap between prefabricated component one;

[0056] Step 4: forming the terraced alluvial soil layer 8;

[0057] The installed device is assembled in step 3 to intercept the soil, silt and organic matter carried by the rainwater, and form the silted soil lay...

Embodiment 2

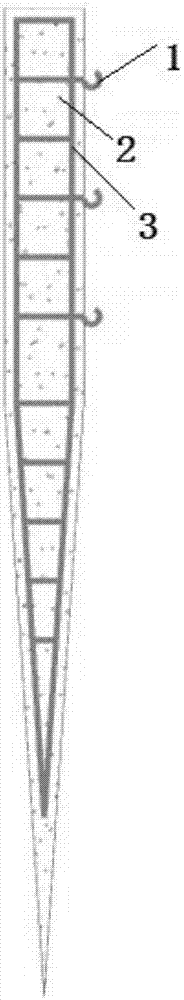

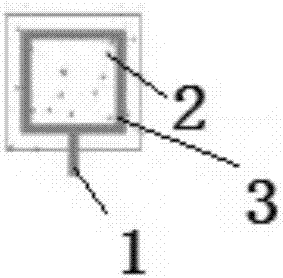

[0078] Such as Figure 1-3 and Figure 5-13 As shown, compared with Embodiment 1, the difference of this embodiment is that the upper section of the prefabricated component one is a cuboid and the lower section is a cone, and a hooking device is fixedly arranged on one side of the upper cuboid, and the prefabricated component The inside of one is provided with a support frame.

[0079] Preferably, the prefabricated component one is made of fine stone concrete 2 , the hooking device in the prefabricated component one is a steel bar prefabricated hook 1 , and the supporting framework inside the prefabricated component one is a threaded steel bar 3 .

[0080] In actual application, the lower section of the prefabricated component is a cone to facilitate ramming into the loess slope, and the upper section is a cuboid to facilitate overall installation and installation. The setting of the hook device makes the placement of the square loess load 6 more stable. The interior of the p...

Embodiment 3

[0082] Such as figure 1 , Figure 4-7 As shown, compared with Embodiment 1, the difference of this embodiment is that the inner dimensions of the mold box 4 are 75 cm, 30 cm, and 90 cm in length, width, and height, respectively, and the upper end of the mold box 4 is open.

[0083] It is preferred that described mold case 4 is custom-made wooden with 2cm thick plank

[0084] Preferably, the formula loess load placed in the wooden mold is a 75cm*105cm national standard sack.

[0085] During concrete implementation, 75cm*105cm national standard sack is placed in wooden mold 4, and formula loess is placed wherein to tamp in national standard sack as load-carrying object, and sews up with thread, preferably sews up with thick twine.

[0086] The present invention adopts this solution, well realizes the functions of the present invention, and is economical and practical in terms of materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com