Glutinous rice flour returning device

A technology of glutinous rice flour and silo body, applied in food science and other directions, can solve the problems of unsanitary, long time-consuming process of returning flour, large natural environment factors, etc., and achieve the effect of accelerating the speed of moisture regaining, fast speed and guaranteeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

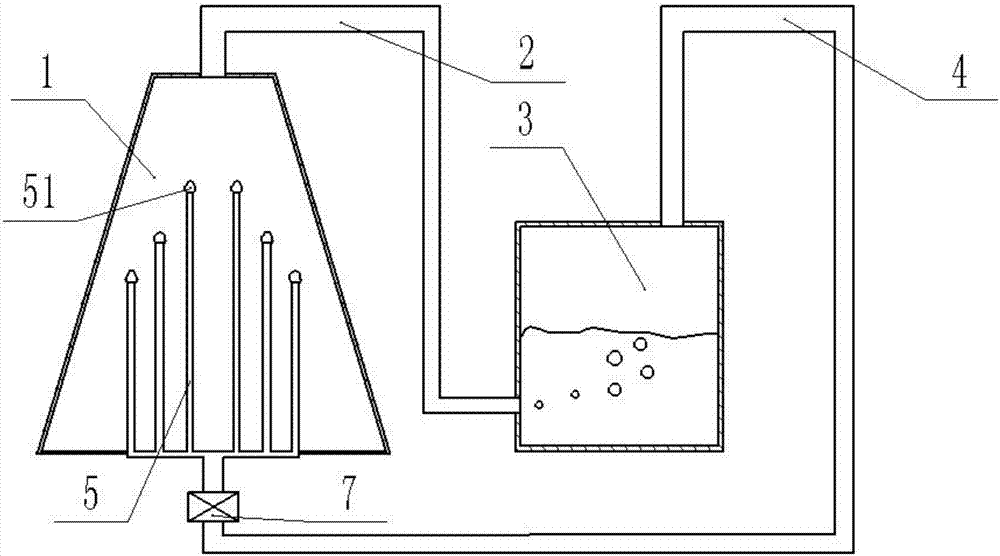

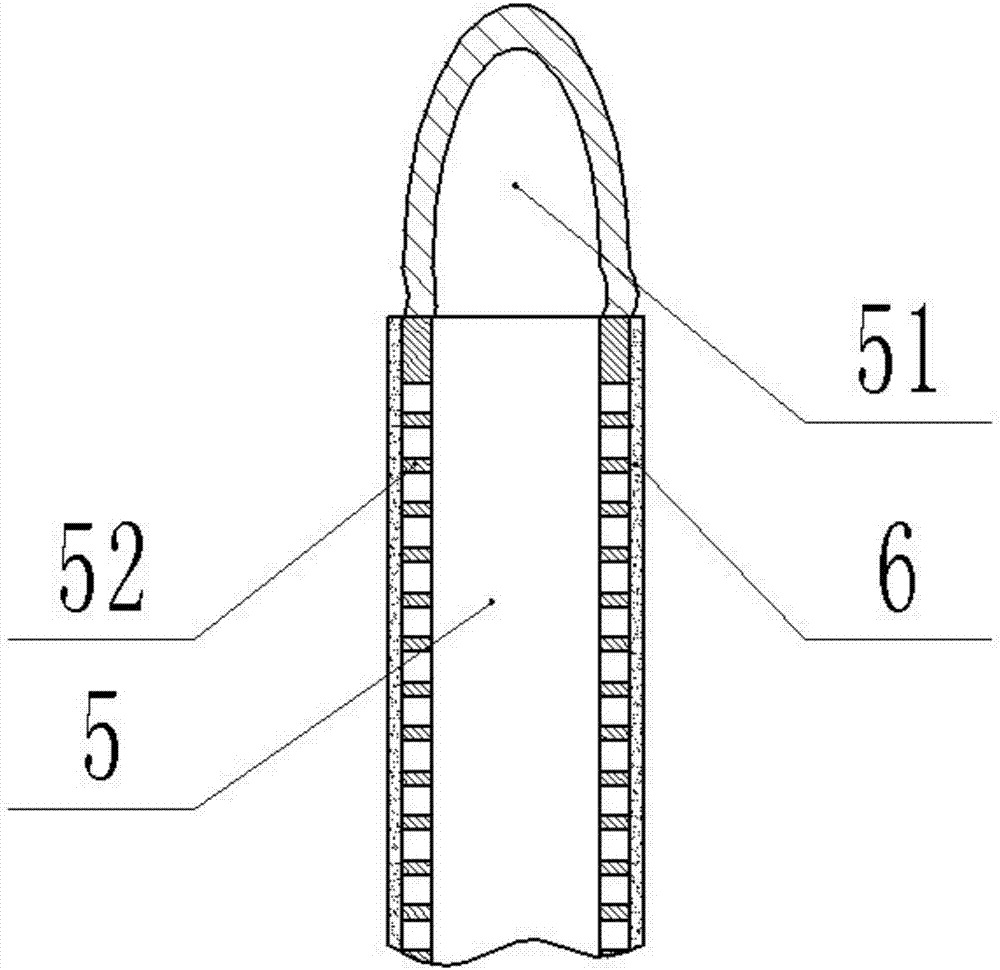

[0026] The reference numerals in the accompanying drawings of the description include: the warehouse body 1, the first pipeline 2, the water tank 3, the second pipeline 4, the air pipe 5, the balloon 51, the through hole 52, the first cotton cloth 6, and the air pump 7.

[0027] Such as figure 1 and figure 2 The shown glutinous rice flour returning device includes a warehouse body 1, a first pipeline 2, a water tank 3 and a second pipeline 4 connected in sequence. The warehouse body 1 is conical, and the smallest diameter end of the warehouse body 1 is located above. The first pipeline 2 communicates with the top of the warehouse body 1 and the bottom of the water tank 3, and the interior of the warehouse body 1 is provided with several vertically arranged ventilation pipes 5, and the ventilation pipes 5 are all communicated with the second pipeline 4, and the second pipeline 4 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com