Double-row ball bearing

A technology for double-row ball bearings and outer rings, applied to bearings, bearing components, shafts and bearings, etc., can solve problems such as retention and reduce the service life of double-row bearings, and achieve improved balance, extended service life, improved reliability and The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

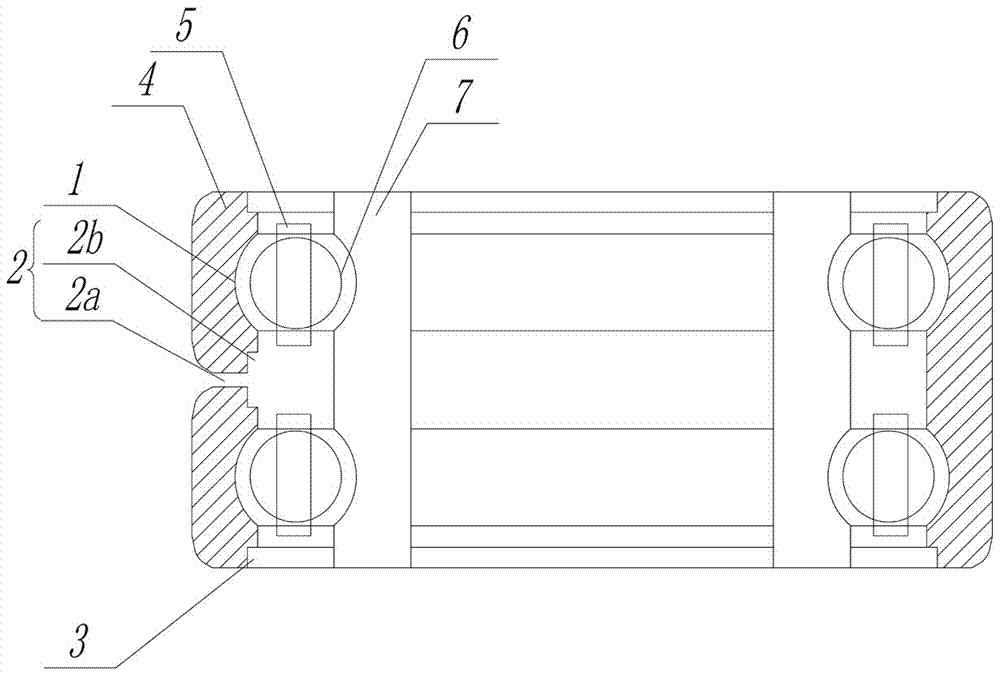

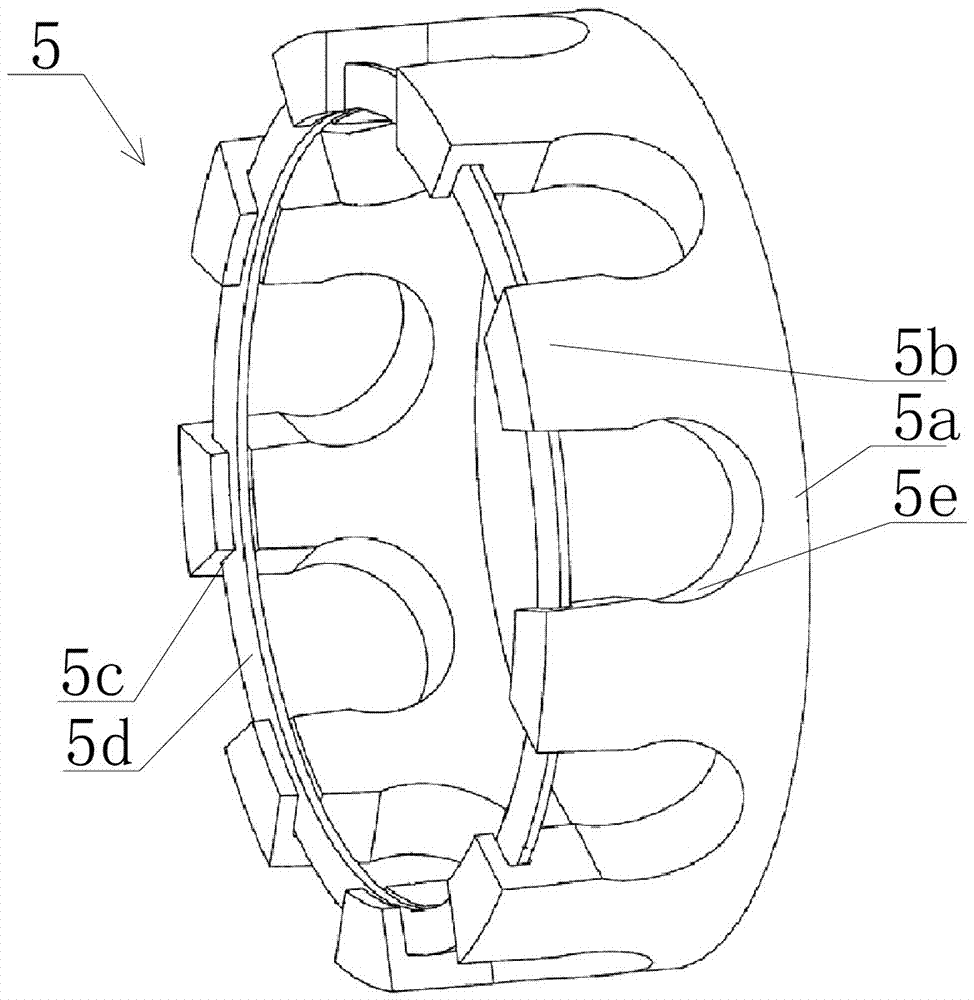

[0018] Double row ball bearing, including outer ring 4, inner ring 7, cage 5, and balls 6; the outer ring 4 is sleeved outside the inner ring 7; the cage 5 and balls 6 are located on the outer ring 4, inner ring 7 Between, and the ball 6 is embedded in the cage 5.

[0019] The outer ring 4 is in the shape of a hollow cylinder, and its inner wall is provided with two parallel raceways 1 . Preferably, the radius of the raceway 1 is 5mm.

[0020] An oil inlet channel 2 is radially opened in the middle of the inner wall of the outer ring 4 ; two raceways 1 are symmetrically arranged on both sides of the oil inlet channel 2 .

[0021] The oil inlet channel 2 includes a small oil inlet hole 2a and a large oil inlet hole 2b that are coaxially arranged and communicated with each other; the diameter of the large oil inlet hole 2b is greater than the diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com