Cold water simulation anti-corrosion system inside high-voltage direct-current converter valve

A high-voltage direct current, converter valve technology, applied in the field of electric power engineering, can solve problems such as metal corrosion, and achieve the effect of inhibiting metal corrosion and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

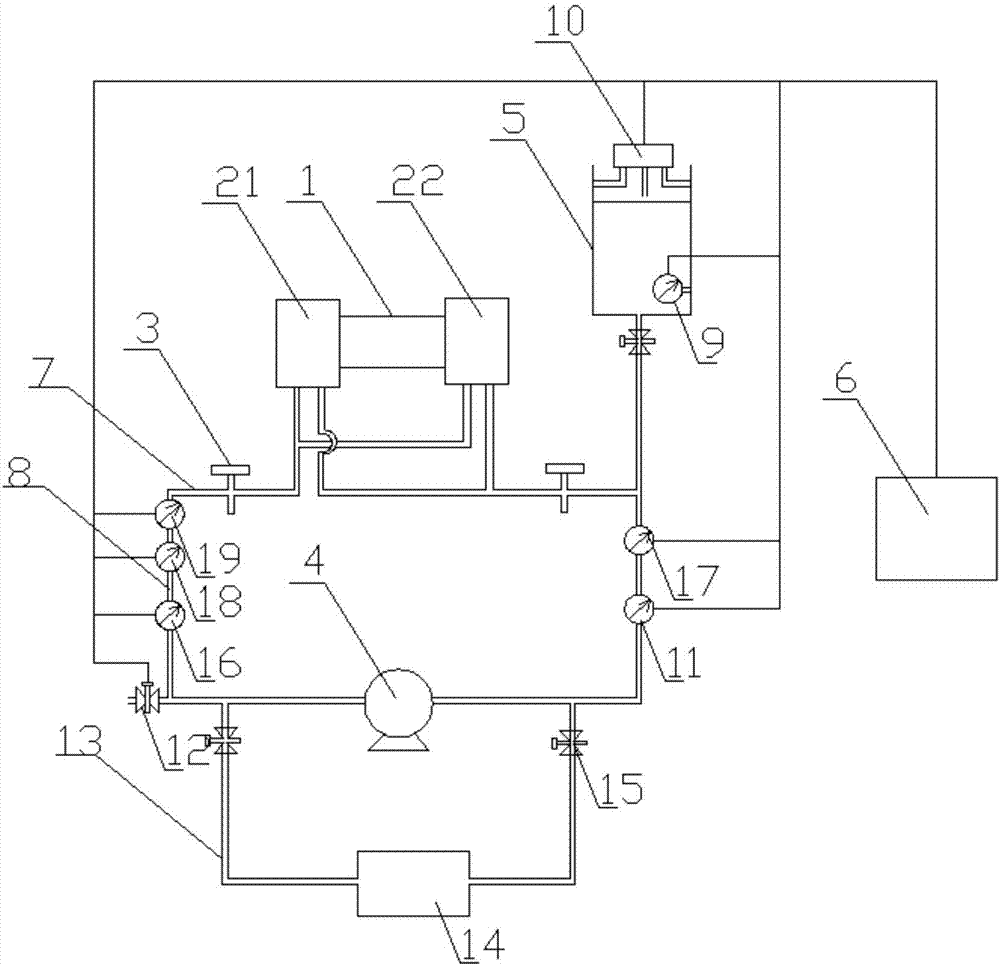

[0028] see figure 1 , is a structural schematic diagram of a simulated anti-corrosion system for internal cooling water of a HVDC converter valve provided in an embodiment of the present application. Depend on figure 1 It can be seen that the system includes a thyristor 1 and a cooler 2 for cooling the thyristor 1, and also includes a voltage equalizing electrode 3, a circulating water pump 4, an expansion tank 5 and a controller 6;

[0029] The cooler 2 communicates with the equalizing electrode 3 and the circulating water pump 4 through pipelines to form a circulation pipeline 7;

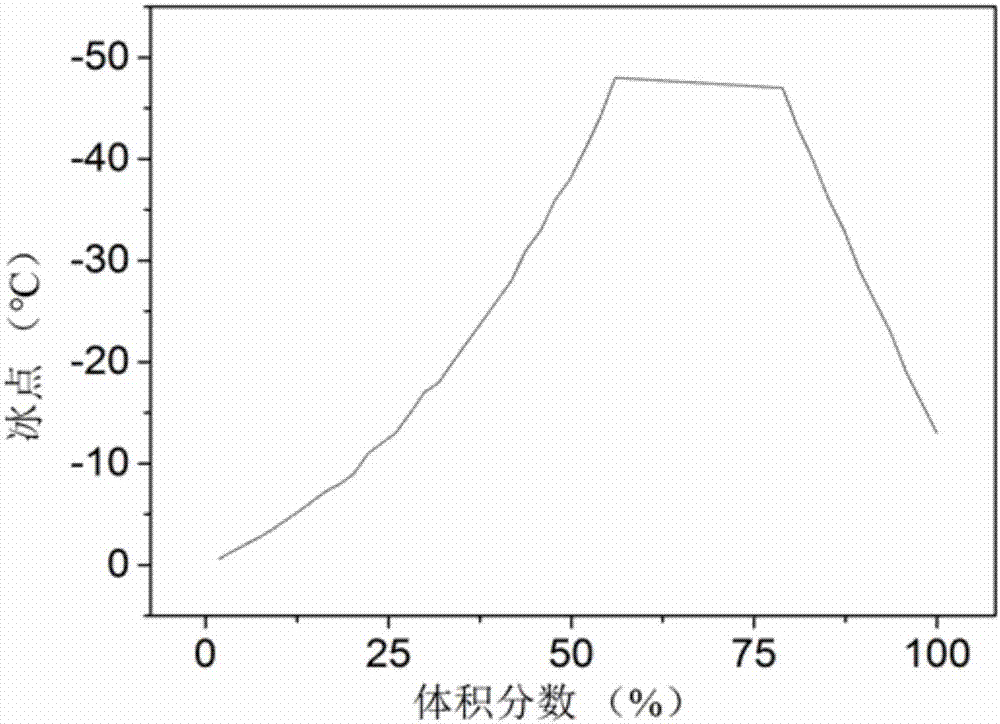

[0030] The circulation line 7 is in communication with the expansion tank 5; the circulation line 7 contains deionized water 8 containing ethylene glycol;

[0031] The expansion water tank 5 is provided with a detection instrument 9 for detecting the concentration of ethylene glycol in the deionized water 8, and is also provided with a liquid addition device 10 for adding ethylene glycol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com