Method for treating printing and dyeing wastewater in textile factory

A printing and dyeing wastewater and textile factory technology, applied in the field of printing and dyeing wastewater treatment equipment, can solve the problem of inconvenient transportation of sludge and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

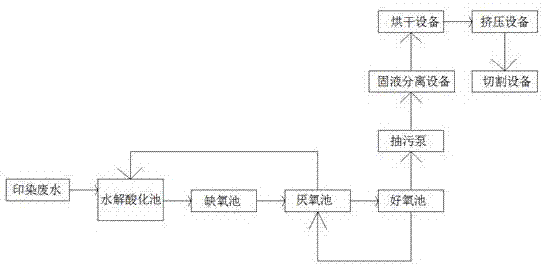

[0027] refer to figure 1 , a method for the treatment of printing and dyeing wastewater in textile mills is proposed in this embodiment, comprising the following steps:

[0028] S1: The printing and dyeing wastewater is first passed into the hydrolytic acidification tank, and the brevis and Alicyclobacillus inoculated in the hydrolytic acidification tank degrade the macromolecular organic matter in the printing and dyeing wastewater;

[0029] S2: The wastewater treated in the hydrolytic acidification tank described in S1 is passed into the anoxic tank, and the Bacillus cereus and Pseudomonas cerevisiae inoculated in the anoxic tank are used for denitrification treatment of the wastewater;

[0030] S3: The wastewater treated in the anoxic pool described in S2 is passed into the anaerobic pool, and the ethanol thermophilic anaerobic bacteria inoculated in the anaerobic pool are used to remove nitrogen and phosphorus from the wastewater. The denitrification acid solution is pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com