Dyeing process of basolan wool

A kind of craft and wool technology, applied in the field of Basolan wool dyeing process, can solve the problems affecting the overall quality and aesthetics of light-colored Basolan wool products, large color lag, color difference or To improve the efficiency of dyeing, improve the overall quality and aesthetics, and reduce knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of dyeing process of Basolan wool comprises the following concrete steps:

[0043] Step S1, hanging yarn into the vat: use the spray vat as the dyeing vat, which is produced in Dalang Zhongshun Boiler Operation Department, Dongguan City; the operator arranges the Basolan wool yarn to be dyed and places it in the steam pipe for fixing ;

[0044] Step S2, washing the yarn: add water to the dyeing vat to wash the yarn to 60°C, and discharge the washing water after 10-15 minutes;

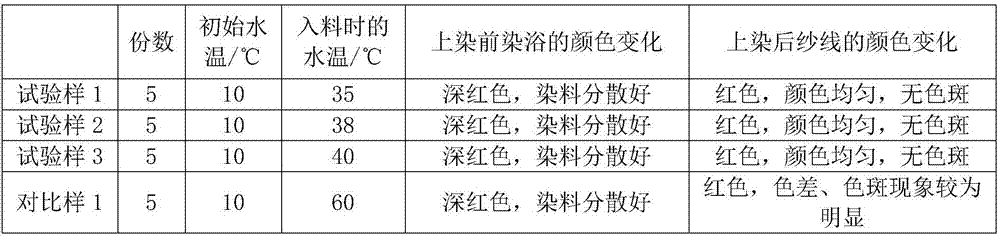

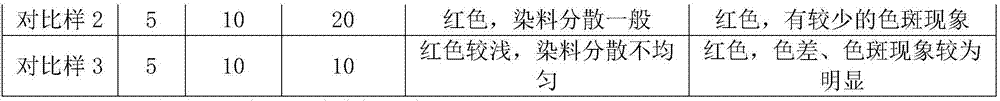

[0045] Step S3, add clear water again into the dye vat, add dark or light colored dye when the water temperature of the clear water is controlled at 35°C, and obtain a dye bath after standing for 6 minutes;

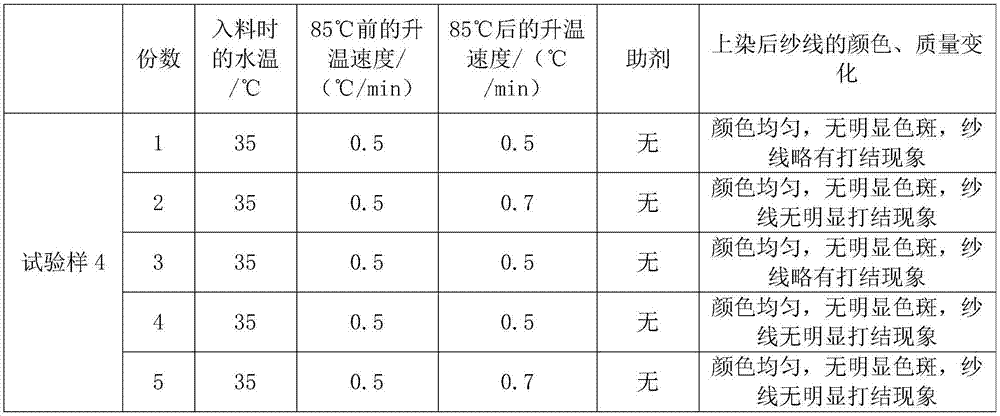

[0046] Step S4, raising the temperature of the dye bath in the dye vat to 98°C at a heating rate of 0.5°C / min;

[0047] Step S5, keeping the temperature of the dye bath at 98°C, keeping the temperature for 55 minutes and then lowering the temperature of the dye bath to...

Embodiment 2

[0049] Embodiment 2: A dyeing process of Basolan wool, the difference from Embodiment 1 is that in step S3, in summer, the water temperature of clear water (i.e. the natural water in the pipeline) is greater than 35°C, and at 38°C At the same time, the operator can directly add water and acid dyes into the dye vat, and let it stand for 5-8 minutes to obtain a dye bath.

Embodiment 3

[0050] Embodiment 3: a dyeing process of Basolan wool, the difference from embodiment 1 is that in step S3, in spring, autumn and winter, the water temperature of the clear water is less than 35°C, and the clear water added in the dye vat After the temperature of the water is raised to 40°C, acid dyes are added, and the dye bath is obtained after standing for 5-8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com